Housing and housing removal machine

A shell and machine technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of high price of mold release agent and epoxy material, unsuitable for automatic machine operation, air bubbles affecting pressure resistance, etc. The filling labor cost is low, the possibility of scratches is reduced, and the product has good pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

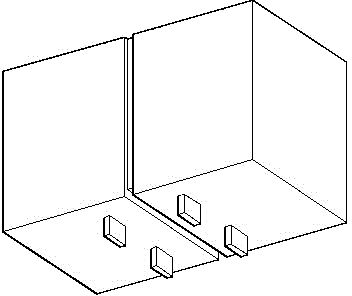

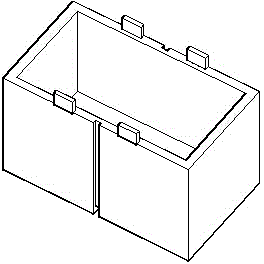

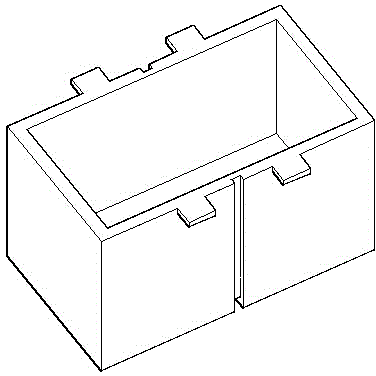

[0029] Put the inner core into figure 1 with 2 In the transformer, after the epoxy potting and curing is completed, put the transformer into the vibrating plate, and after screening, the transformers are arranged in an orderly manner with the pins facing upward and the bottom of the shell downward, entering such as Figure 8 In the shown rails, screened into an orderly arrangement of matching grooves along the bottom ears, along the rails into the dehulling machine's Figure 9 with 10 In the groove of the gripper, the gripper moves to the two sides, the outer shell is torn off, and the finished transformer with epoxy as the outer part falls into the finished product box, and this implementation is completed.

Embodiment 2

[0031] Put the inner core into figure 1 with 2 In the square transformer, after the epoxy potting and curing is completed, use two vices to clamp the ears on both sides of the groove respectively, tear the shell along the groove, and leave the transformer without a shell encapsulated by epoxy. To complete this implementation, of course, if the manpower is large, you can also use two vices to clamp the ears on both sides of the bottom groove, tear the shell along the groove, and leave the transformer without a shell encapsulated by epoxy to complete this implementation.

Embodiment 3

[0033] Put the inner core into Figure 4 with 5 In the cylindrical transformer, after the epoxy potting and curing is completed, use two vices to clamp the ears on both sides of the groove respectively, tear the shell along the groove, and leave the transformer without a shell encapsulated by epoxy , to complete this implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com