A lcc-hvdc topology with auxiliary commutation circuit

An LCC-HVDC, commutation circuit technology, applied in electrical components, power transmission AC networks, output power conversion devices, etc., can solve the problems of high equipment cost, limited application, and many additional components, and achieves fewer additional components. Improve the ability to resist commutation failure, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

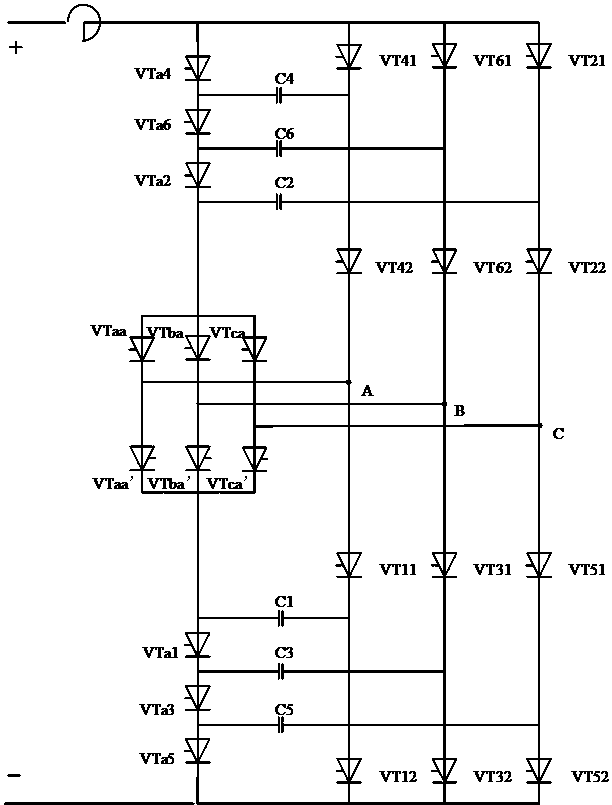

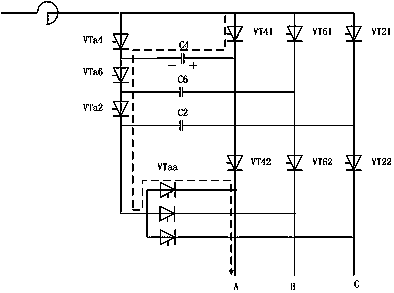

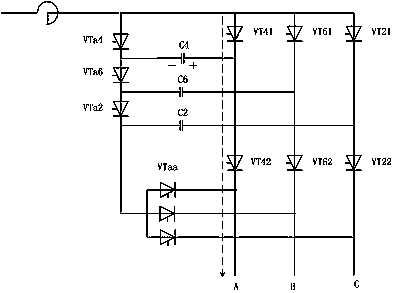

[0023] The invention provides an LCC-HVDC topology with an auxiliary commutation circuit, which includes six valve arms of a six-pulse converter, two sets of auxiliary commutation circuits and six capacitors. Each group of auxiliary commutation circuits is composed of thyristors connected in series with a star-connected structure composed of thyristors; each group of auxiliary commutation circuits is connected in parallel with three valve arms through a capacitor, and the capacitor divides each group of auxiliary commutation circuits. It is a three-segment structure, and each valve arm is divided into two-segment structures; each group of auxiliary commutation circuits is respectively connected to the AC systems A, B, and C through a star thyristor structure. The auxiliary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com