Clamp for assembling and expanding conducting bar of motor rotor

A technology for tightening fixtures and motor rotors, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of unfixed guide bars at both ends, not tight guide bars, and unsafety, so as to improve positioning accuracy and expansion effects. The effect of reducing labor intensity and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

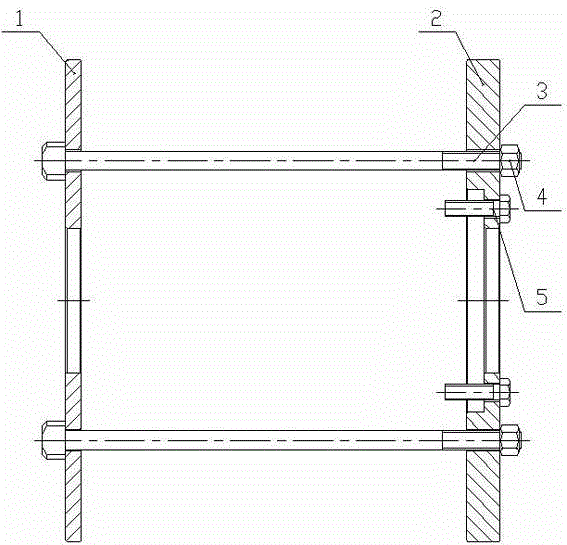

[0009] Such as figure 1 As shown, the present invention comprises a driving end pressing plate 1 and a non-driving end pressing plate 2, the driving end pressing plate 1 and the non-driving end pressing plate 2 are all circular steel plates, and four The screw rod 3 is connected and fixed with the nut 4; the four circular holes connecting the screw rod 3 on the drive end pressure plate 1 correspond to the four ventilation holes on the rotor core; the outer circle size of the non-drive end pressure plate 2 is smaller than the rotor core The outer diameter size and the inner circle size are larger than the diameter of the rotor core gear shaft. There is an annular step on the inner ring of the non-drive end pressure plate 2, and the annular step is set on the side of the transmission end pressure plate 1. There are four bolts 5 evenly connected along the circumference on the annular step; working principle: when the present invention is in use, the nut 4 on the four screw rods 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com