A grain moisture detection device

A detection device and grain moisture technology, which is applied in the direction of testing food, material inspection products, etc., can solve the problems of different rolling positions of metal rollers, inconsistent particle sizes, and affecting moisture monitoring, so as to improve the overall adaptability and increase the rolling force , the effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as limiting the present invention.

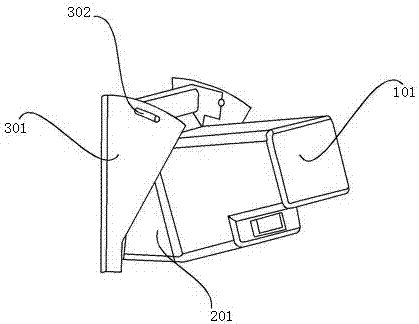

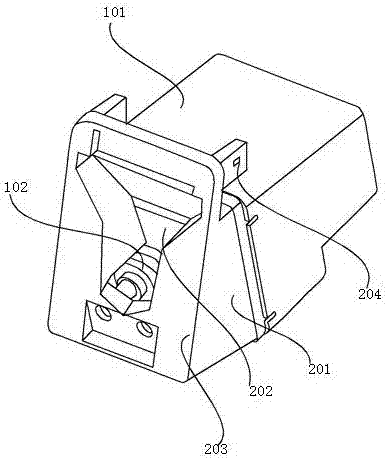

[0018] as attached Figure 1-3 Shown, a kind of grain moisture detection device, it comprises a moisture detection device body, a diversion box assembly and a position adjustment assembly, wherein:

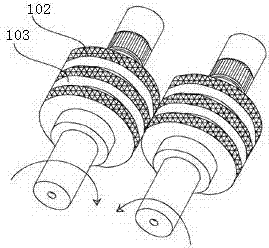

[0019] A moisture detection device body, which has a moisture detection housing 101 and a roller assembly located in the moisture detection housing 101, the roller assembly includes a symmetrically arranged roller 102, the roller 102 is provided with a circumferential groove 103; the roller 102 rotates relatively.

[0020] A guide box assembly, which has a connection housing 201, the connection housing 201 is provided with an opening 202, and the opening 202 is adapted to the roller assembly; one end of the connection housing 201 is fixedly connected with the moisture detection hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com