High-speed train shock absorber universal test bench

A technology for high-speed trains and shock absorbers, which is applied in railway vehicle testing, machine/structural component testing, vibration testing, etc. It can solve problems such as low precision, high cost, and poor performance of shock absorber test benches, and achieve convenient installation It has the effect of unloading, convenient maintenance or replacement, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further explained and illustrated in the form of specific embodiments in conjunction with the accompanying drawings.

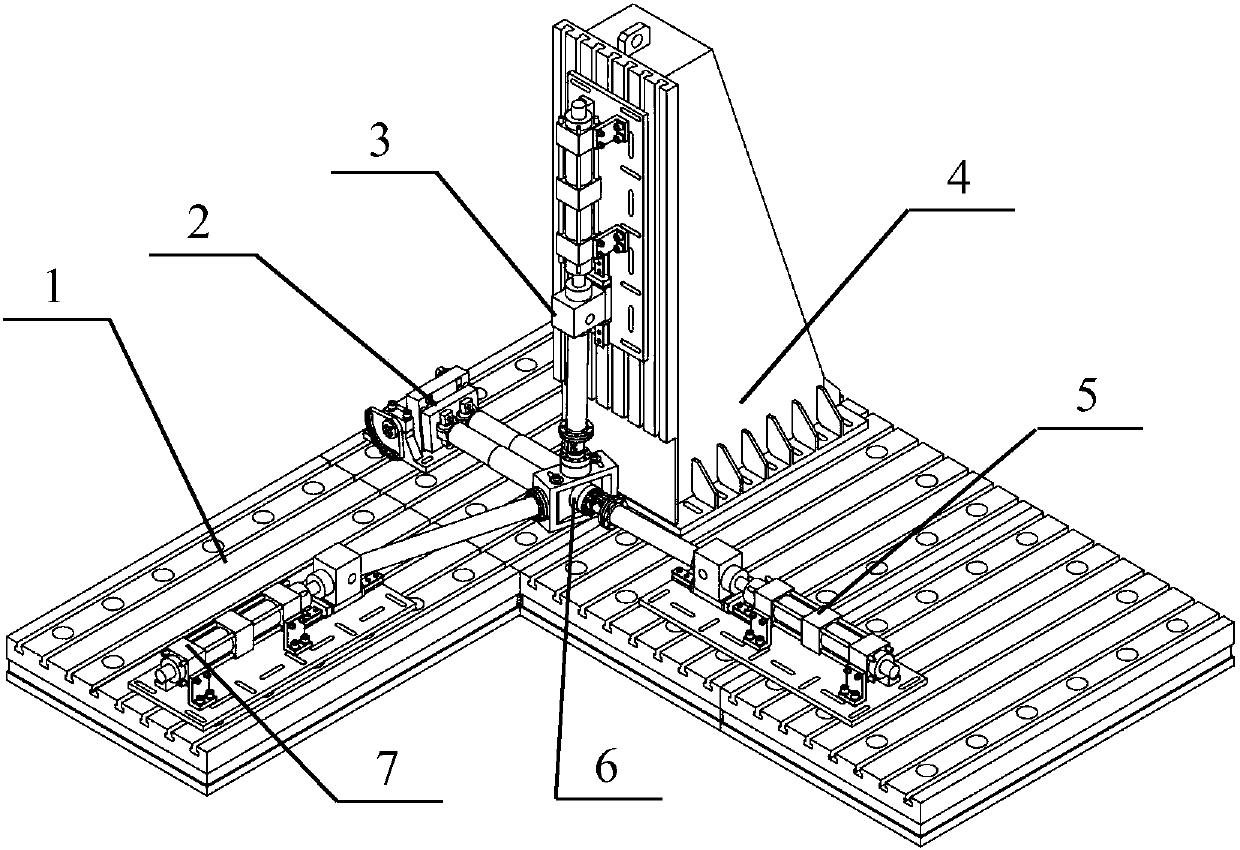

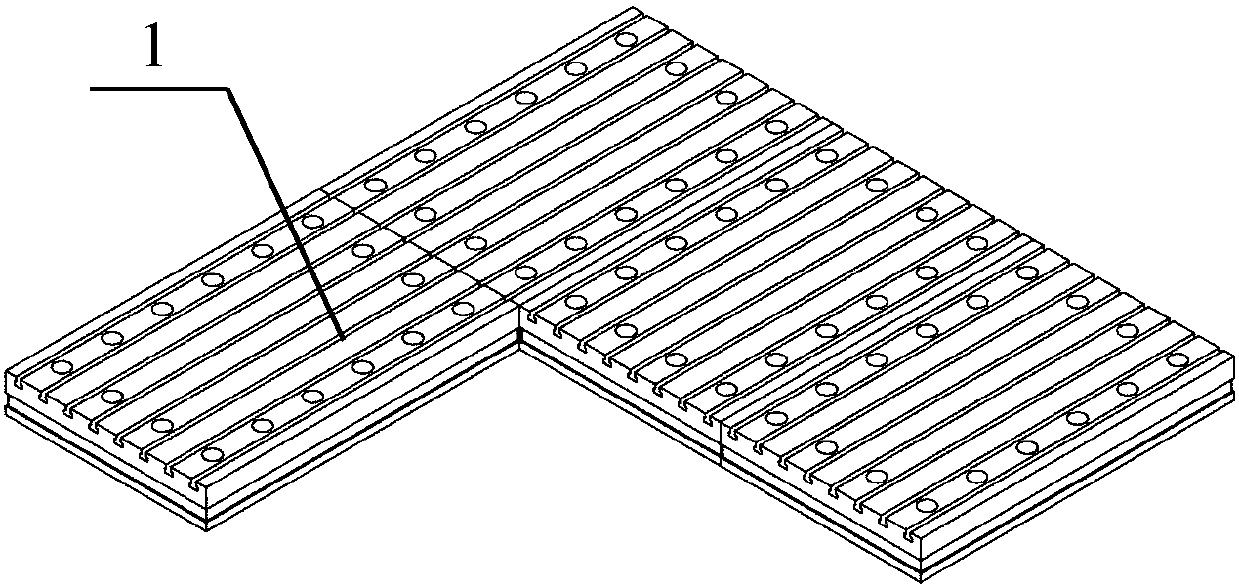

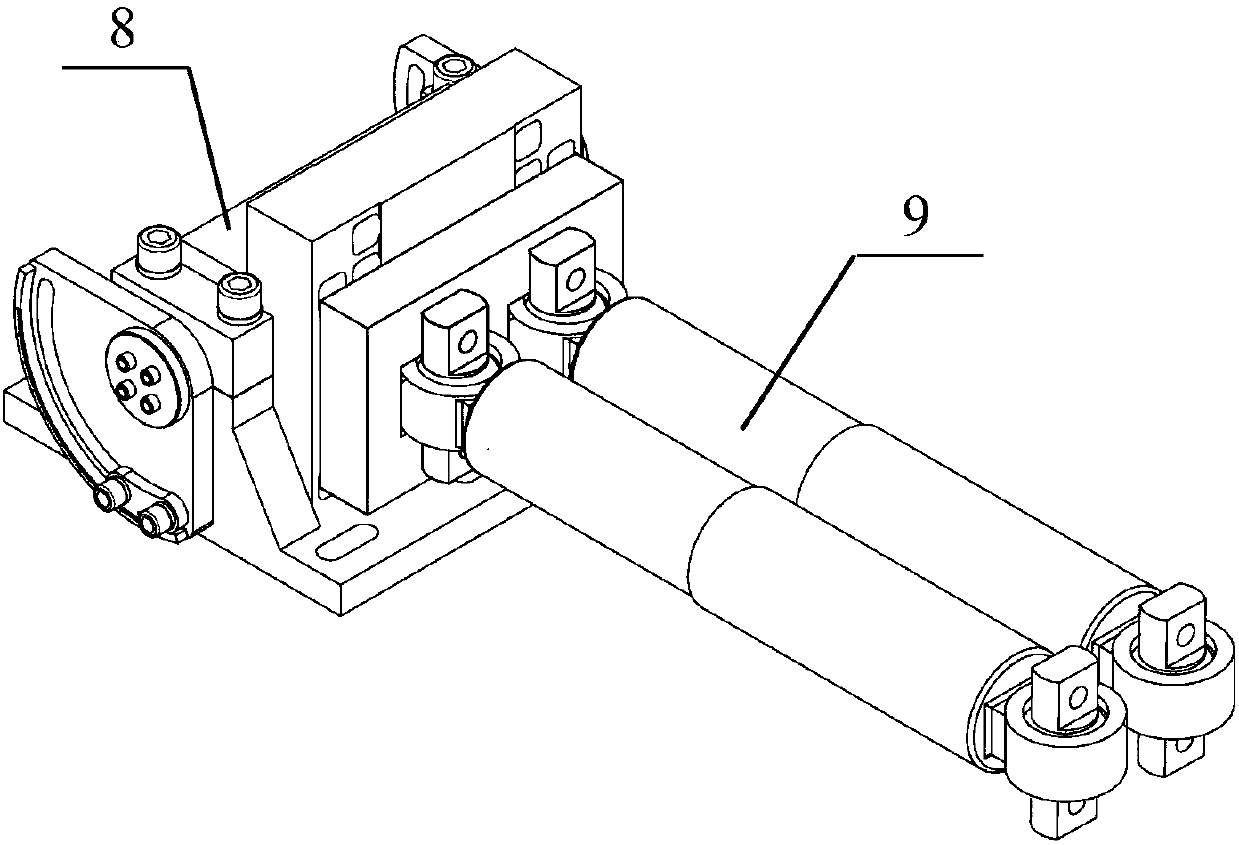

[0051] refer to Figure 1 to Figure 2 , high-speed train shock absorber universal test bench includes cast iron installation platform 1, shock absorber universal support assembly 2, vertical actuator assembly 3, support column 4, lateral actuator assembly 5, shock absorber The variable angle installation assembly 6 and the longitudinal actuator assembly 7; the vertical actuator assembly 3, the transverse actuator assembly 5 and the longitudinal actuator assembly 7 have the same structure.

[0052] The shock absorber universal support assembly 2, support column 4, transverse actuator assembly 5 and longitudinal actuator assembly 7 are fixed and installed on the upper working surface of the cast iron installation platform 1 through T-shaped bolts, and can be installed according to the test Need to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com