Engine torsional vibration simulation method for automobile test bed

A technology of automobile test and simulation method, which is applied in the direction of internal combustion engine test, etc., which can solve the problems of unfavorable environmental protection of exhaust gas, reduce the service life of parts, and affect the test of transmission, etc.

Active Publication Date: 2016-06-08

CHONGQING UNIV OF TECH +1

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In recent years, the NVH problem of automobiles has attracted more and more attention from engineers. The periodic fluctuation of engine torque will cause torsional vibration of the drive train, resulting in noise and reducing the service life of components.

If the transmission gears are not properly designed, the engine cycle torque pulsation can cause transmission rattle, which can affect the NVH quality of the car

Carrying out NVH test with physical engine drive has many disadvantages, 1) The engine fuel is flammable, and it is easy to produce dangerous factors such as fire during its working process, and its exhaust gas is not conducive to environmental protection

2) The NVH test mainly measures the noise problem of the transmission under test, and the higher noise of the real engine in the test will affect the NVH test of the transmission

3) In the initial stage of powertrain development, usually the matching engine is also under development and testing, so it is difficult to obtain the engine as a drive to perform NVH and other performance tests on the powertrain on an indoor bench

Accurate engine models have been discussed in many literatures, such as black-box models and models based on physical structures, etc., because these models require a large amount of engine development data or detailed engine design parameters, these parameters are not easy to obtain in drive train tests, and Traditional physical models are difficult to meet the requirements of high dynamic control response when simulating engine combustion characteristics with complex mathematical calculations, so these models are not suitable for dynamic simulation of drive train benches

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0044] Embodiment: The engine torsional vibration simulation method of the automobile test bench is mainly applied to the indoor automobile transmission train test bench, and the periodic pulsating torque (i.e. torsional vibration) of the engine is simulated by the driving motor. Provide a realistic engine operating condition to achieve the purpose of performance testing of clutches, transmissions and other drive train components.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

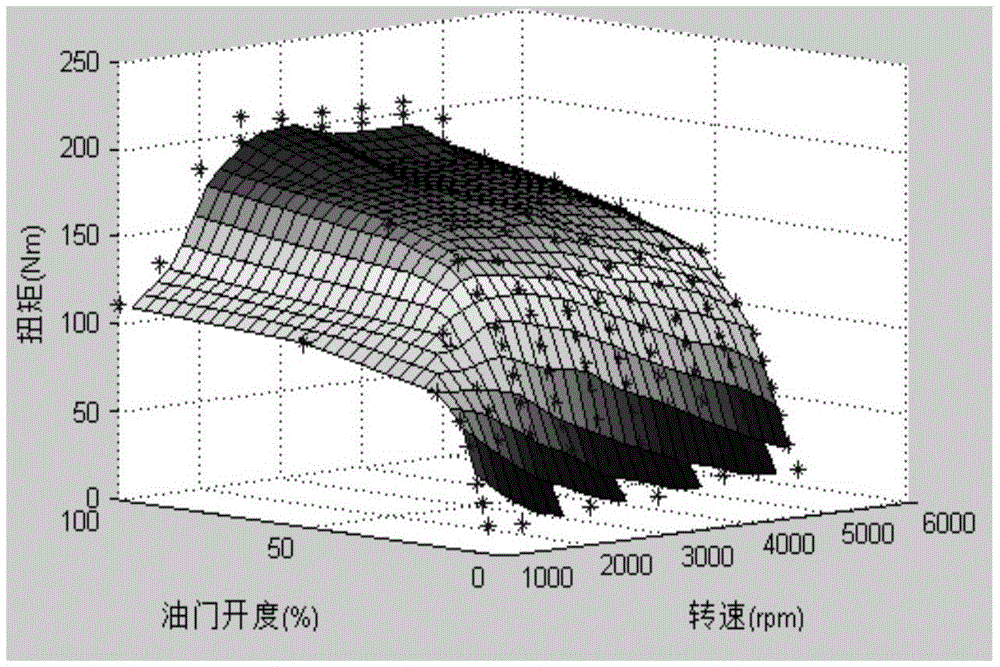

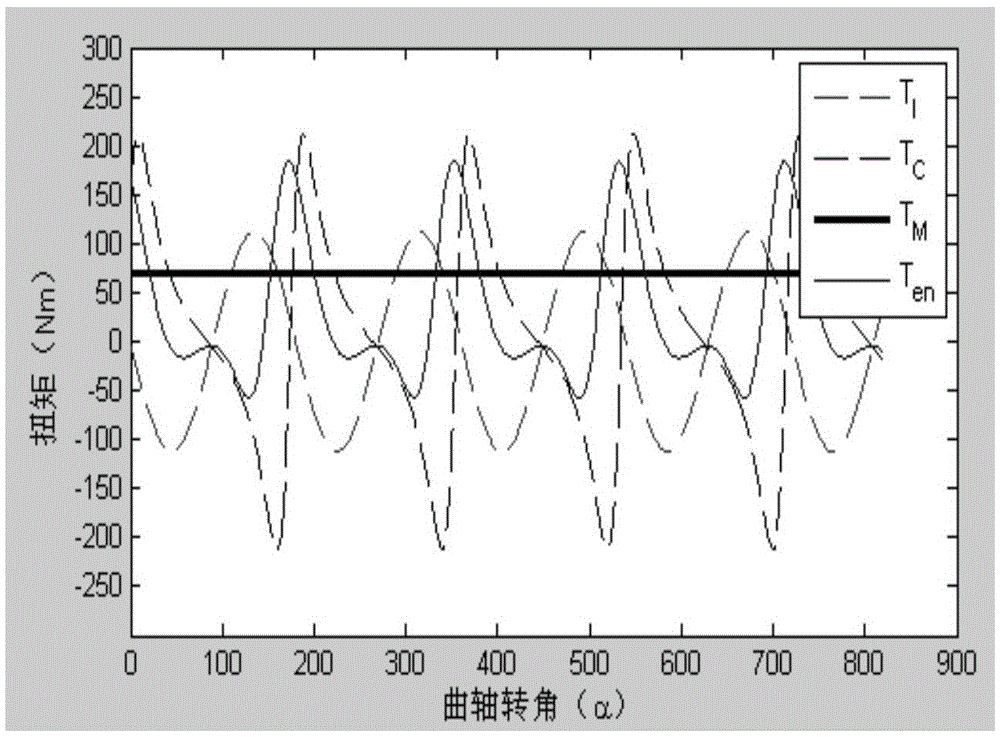

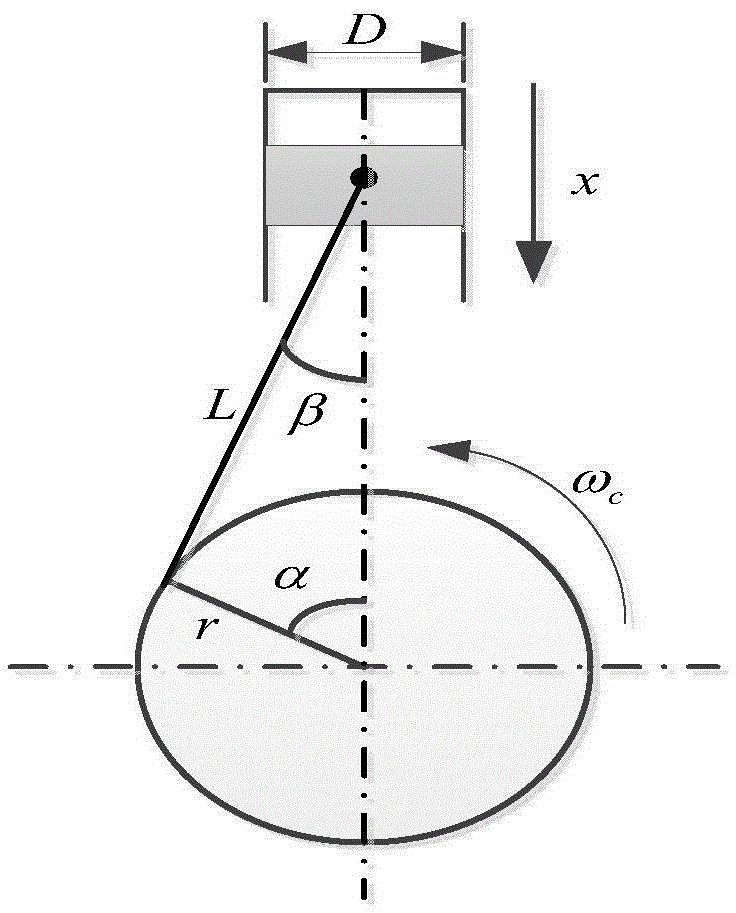

The invention discloses an engine torsional vibration simulation method for an automobile test bed. The method comprises the steps of 1) establishing a "throttle opening degree-rotating speed-torque" model of an engine according to the intrinsic parameters of the engine; 2) establishing an inertia torque solution model and obtaining an inertia torque TI; 3) establishing a combustion torque solution model and obtaining a combustion torque TC; 4) fitting an average torque TM, the inertia torque TI and the combustion torque TC to obtain the input torque of the engine, namely the total torque Ten of the engine. According to the technical scheme of the invention, the above method is high in simulation accuracy, good in real-time performance, and small in calculation amount. Meanwhile, the high-dynamic control response requirement during the periodic torque pulsation (torsional vibration) simulating process of the engine can be met.

Description

technical field [0001] The invention relates to a method for simulating the performance test of an automobile engine, in particular to a method for simulating the torsional vibration of an engine on an automobile drive train test bench. Background technique [0002] In recent years, the NVH problem of automobiles has attracted more and more attention from engineers. The periodic fluctuation of engine torque will cause torsional vibration of the drive train, which will generate noise and reduce the service life of parts. If the transmission gears are not properly designed, engine cycle torque ripple can cause transmission rattle, which can affect the NVH quality of the car. There are many disadvantages in using real engine to drive NVH test. 1) Engine fuel is flammable, and it is prone to fire and other dangerous factors during its working process. At the same time, the exhaust gas it emits is not conducive to environmental protection. 2) The NVH test mainly measures the noi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M15/12

CPCG01M15/12

Inventor 李文礼石晓辉施全王晶晶易鹏

Owner CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com