Extractor hood

The technology of a range hood and a smoke panel is applied in the field of range hoods, which can solve the problems of inability to expand the working distance of the negative pressure area of the left and right chambers of the fume collecting hood, poor smoke blocking effect, and oil fume escape, so as to reduce the chance of escape, Good smoke blocking effect and the effect of expanding the action distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

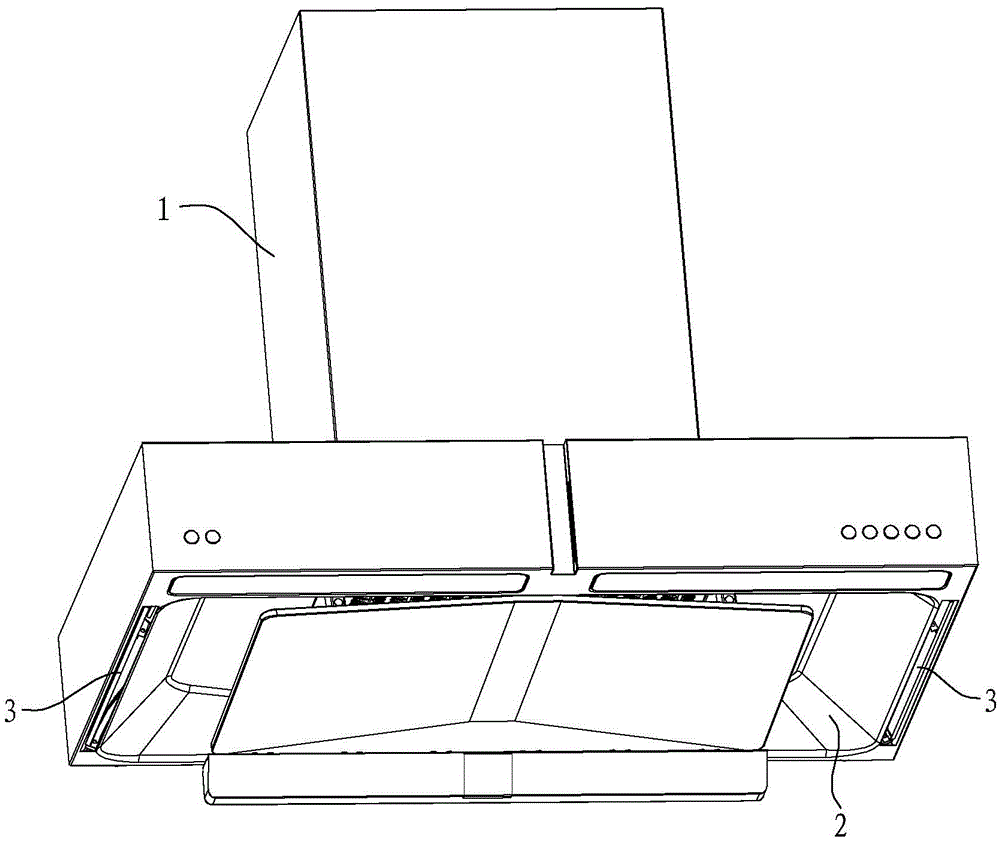

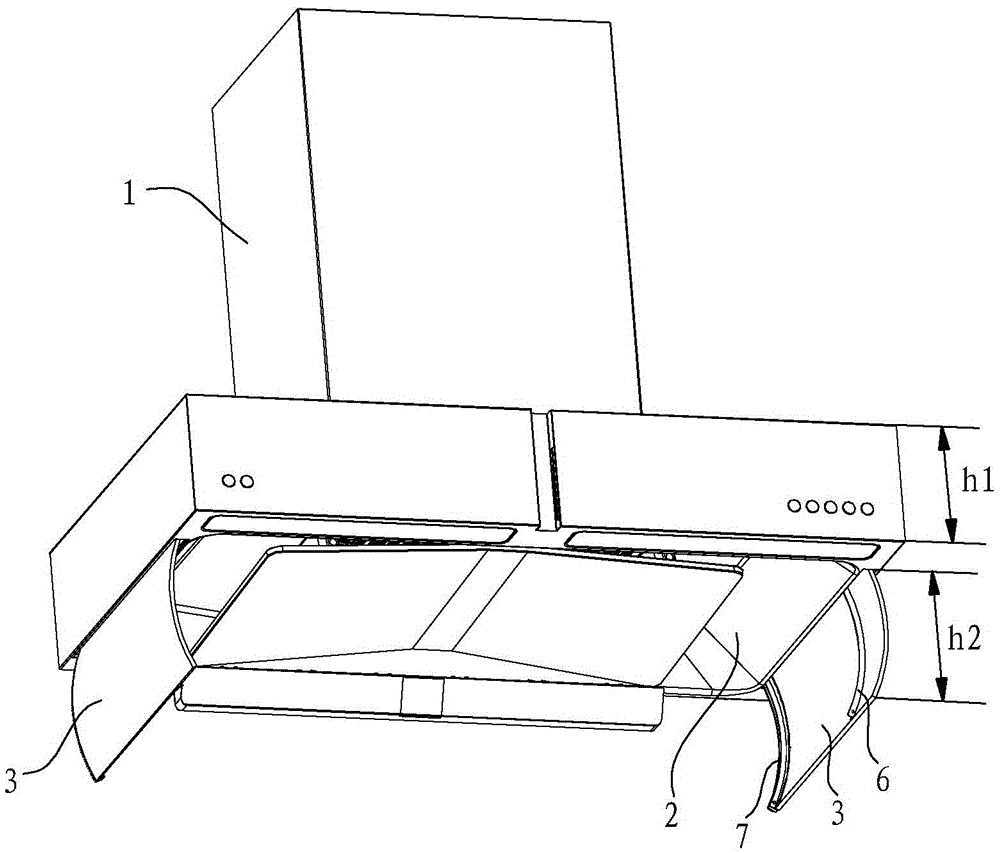

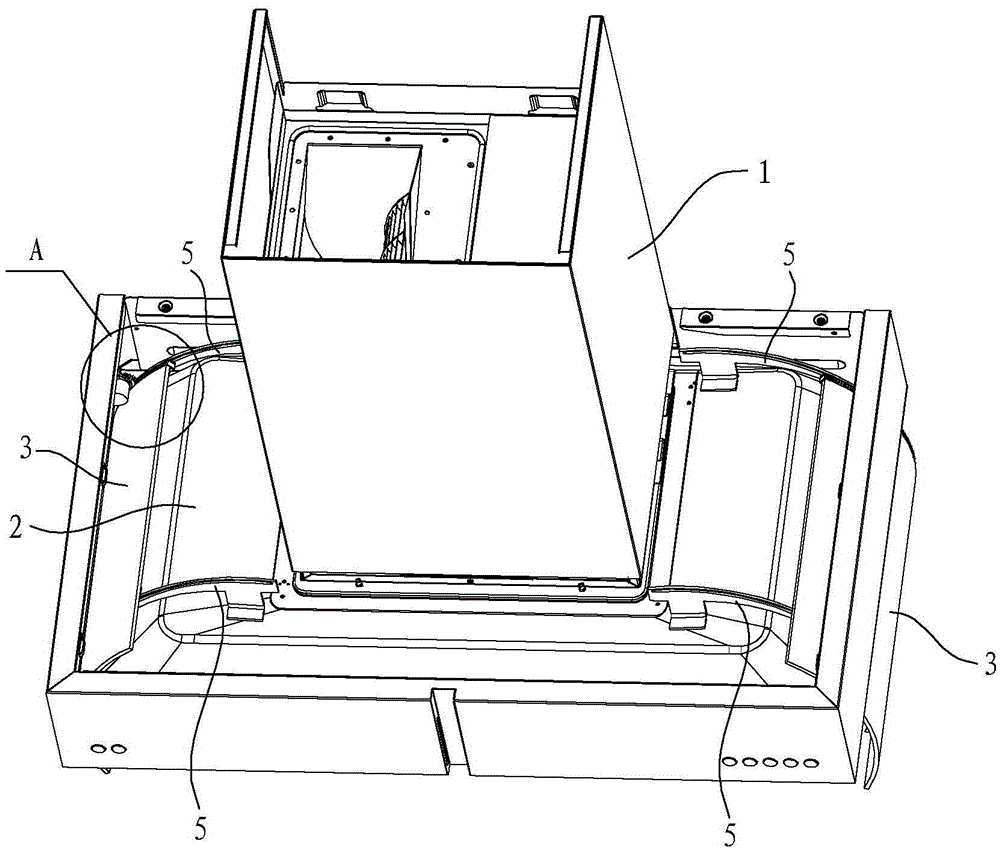

[0023] Such as Figure 1 to Figure 6 As shown, the range hood in this embodiment includes a fan cover 1 and a smoke collection hood 2, the smoke collection hood 2 is arranged under the fan cover 1, and movable smoke baffles 3 are installed on the left and right sides of the smoke collection hood 2, The movable smoke baffle 3 is an arc-shaped plate with the concave surface facing downwards. The movable smoke baffle 3 is retracted upwards into the smoke collection hood 2 or protrudes downwards to the outside of the smoke collection hood 2 under the drive of the driving mechanism.

[0024] Arc-shaped guide brackets 5 are respectively installed on the front and rear sides of the inside of the smoke collecting hood 2, and arc-shaped guide brackets 5 are provided with arc-shaped grooves 51. . A front bracket 6 and a rear bracket 7 are respectively fixed on the front and rear sides of the movable smoke baffle 3 , and rollers 8 capable of rolling along arc grooves 51 are arranged on ...

Embodiment 2

[0029] Such as Figure 7 and Figure 8 As shown, the driving mechanism of the range hood in this embodiment adopts the second driving mechanism 42, and the movable smoke baffles 3 on both sides are retracted into the smoke collecting hood 2 synchronously or extended synchronously under the driving of the second driving mechanism 42. Out to the outside of the fume collecting hood 2. Specifically, the second driving mechanism 42 includes a cylinder 421, a cylinder push rod 422, a first connecting rod 423 and a second connecting rod 424. The cylinder 421 is fixed in the fan housing 1, and the cylinder push rod 422 is vertically arranged on the cylinder 421. above, and the cylinder push rod 422 is located in the middle above the smoke collecting hood 2 and close to the front side of the smoke collecting hood 2, the upper ends of the first connecting rod 423 and the second connecting rod 424 are hinged to the lower end of the cylinder pushing rod 422, the first The lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com