Profiled steel structure beam column joint for reverse construction of stiffened structure and construction method

A technology of beam-column joints and construction methods, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of excessive cross-sectional size of beam-column joints, dense steel bars, and affecting building structures, etc., and achieve efficient construction methods. Save construction cost and promote the effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

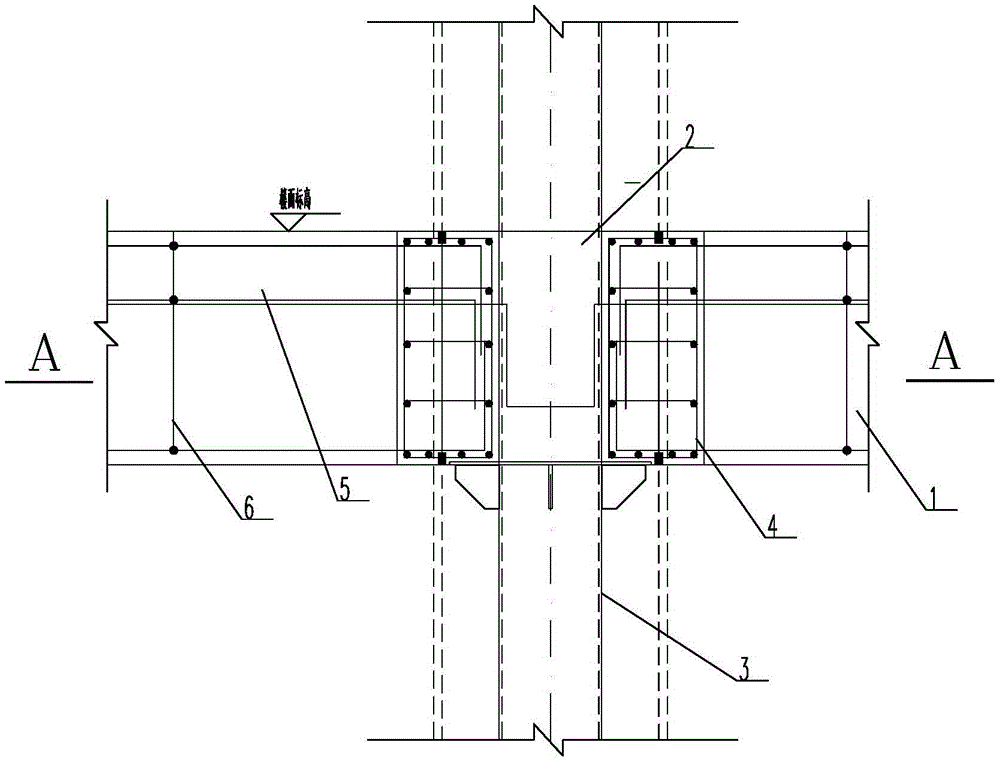

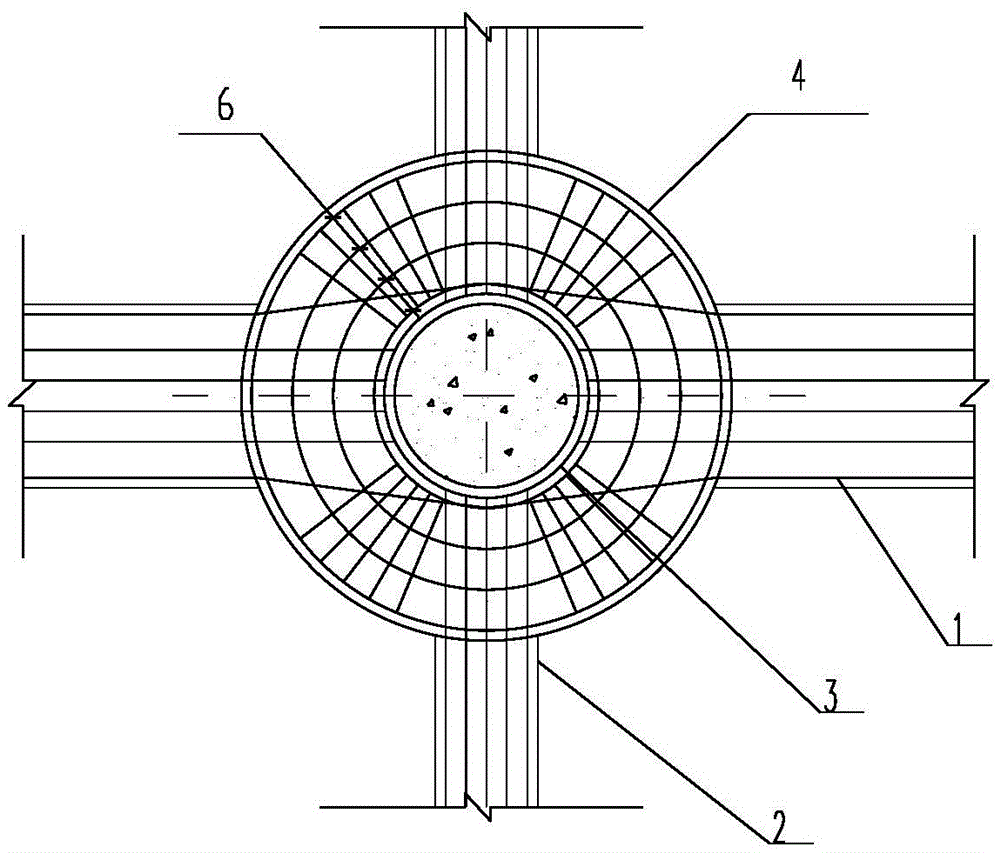

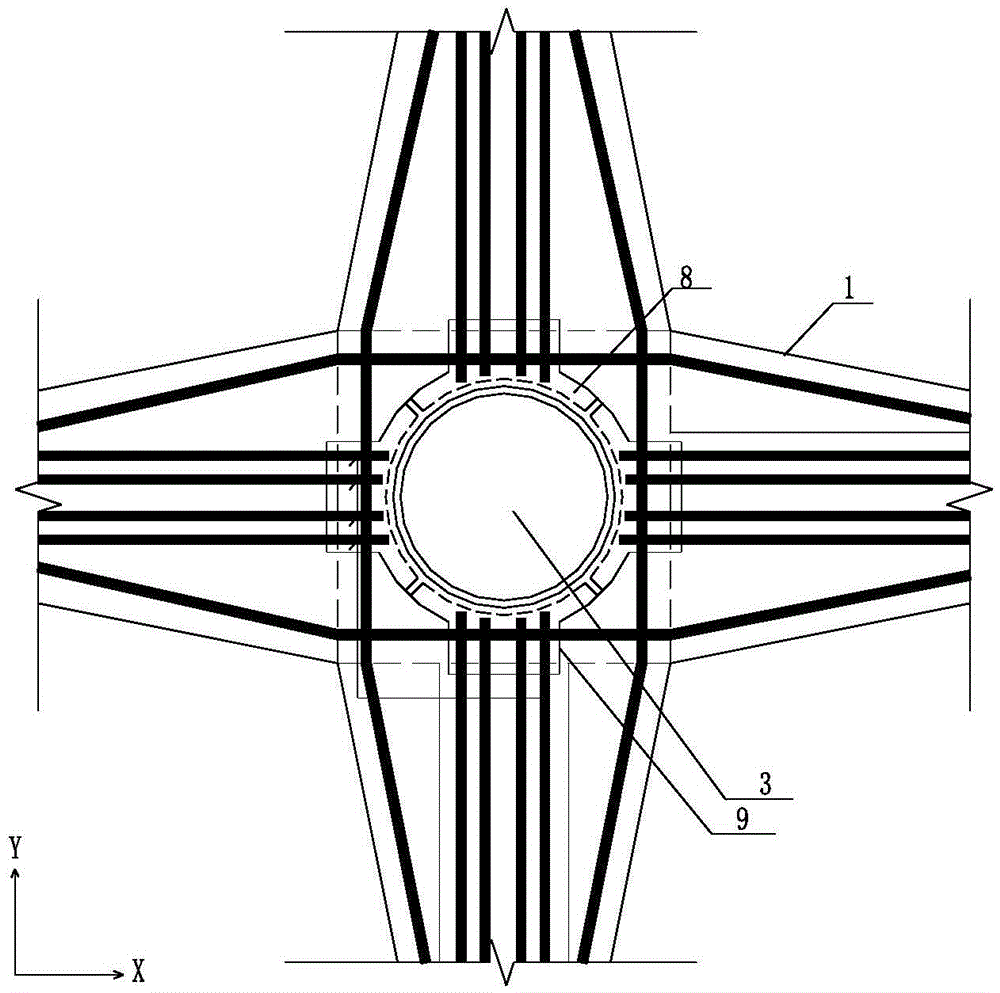

[0034] Such as Figure 3 to Figure 7 As shown, the steel structure beam-column node of the stiff structure is reversed. The stiff structure includes frame beams 1 and frame columns 10 that are vertically intersected and fixed. There is a circular tube column 3 inside, and the H-shaped steel beam and the circular tube column 3 are shaped steel structures. The outer wall of the circular tube column 3 at the beam-column node is welded with two horizontally parallel steel ring plates 8, and the H-shaped steel ring plate near the beam-column node The end of the beam is sandwiched between two steel ring plates 8, and the steel ring plate 8 is also provided with a cantilevered steel plate 9 along the length direction of the frame beam 1, and the cantilevered steel plate 9 is consistent with the elevation and thickness of the steel ring plate 8 .

[0035] Specifically, a pair of horizontally parallel steel ring plates 8 are welded to the outer wall of the round pipe column 3 at the b...

Embodiment 2

[0042] Correspondingly, this embodiment provides a construction method for a steel structure beam-column joint of a rigid structure reversed method. Please refer to Figure 3 to Figure 7 , a construction method of a steel structure beam-column joint with a rigid structure inversion method, the construction method includes the following steps:

[0043] S001: Make the steel ring plate 8 standby: calculate the theoretical size of the steel ring plate 8, and establish the finite element calculation model of the steel ring plate 8, so as to determine the actual size of the steel ring plate 8. In this embodiment, large-scale general-purpose finite element software ANSYS12.1 is used, and the round pipe column 3 and the steel ring plate 8 with the cantilevered steel plate 9 both adopt SEHLL93 units, and both ends of the round pipe column 3 are consolidated. The steel material is Q345B, which adopts the ideal elastic-plastic constitutive model, and the yield strength is 345MPa. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com