Preparation method of HOY spring wire

A spring yarn and spinning technology, applied in the field of spinning, can solve the problems of many broken ends, and achieve the effect of excellent performance and good coiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the first embodiment, the process of HOY satisfies the following conditions:

[0040]

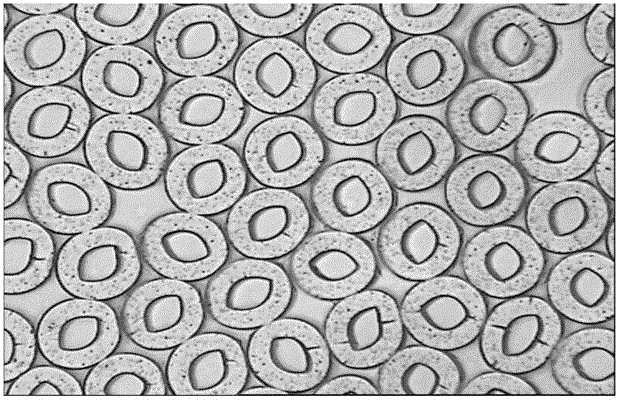

[0041] The cross-sectional photos of the obtained HOY wire are as follows figure 1 As shown, the HOY silk obtained in embodiment 1 is detected, and the detection data:

[0042] Fineness 162.8dt

[0043] elongation 56.19%

[0044] strength 3.56CN / dtex

[0045] boiling water 4.2% .

Embodiment 2

[0047] In the second embodiment, the process of HOY satisfies the following conditions:

[0048]

[0049] The HOY silk that embodiment 2 obtains is detected, and detection data:

[0050] Fineness 166.3dt

[0051] elongation 54.2%

[0052] strength 3.31CN / dtex

[0053] boiling water 4.2% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com