A method for preparing a medium-low temperature and long-term oxidation-resistant coating on the surface of a carbon/carbon composite material

A technology of carbon composite material and anti-oxidation coating, which is applied in the field of anti-oxidation of carbon/carbon composite materials, and can solve the problems such as difficulty in achieving anti-oxidation of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

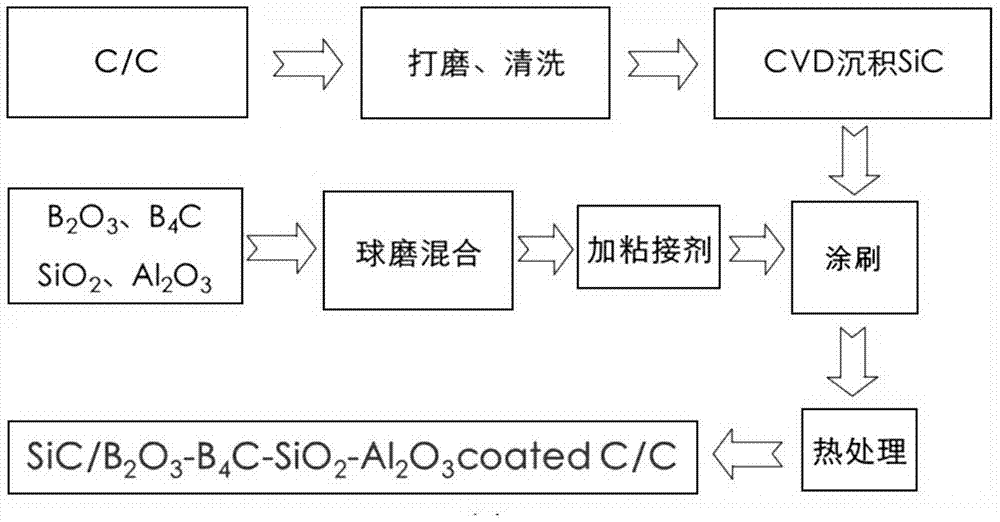

Method used

Image

Examples

Embodiment 1

[0030] The carbon / carbon sample is pretreated first. Choose a density of 1.6g / cm 3 The C / C composite material was polished with 400# silicon carbide sandpaper, ultrasonically oscillated in distilled water for 60 minutes, and then rinsed repeatedly with distilled water; the cleaned carbon / carbon composite material was dried at 160°C for 48 hours for later use.

[0031] Deposit a silicon carbide coating. The carbon / carbon sample after the above treatment is placed in a graphite crucible and placed in a chemical vapor deposition furnace for silicon carbide deposition. Small holes are drilled at the bottom of the graphite crucible to ensure gas circulation. The deposition temperature is 1000°C, the deposition pressure is 5mmHg, the flow rate of trichloromethylsilane (MTS) is 80g / h, and the flow rate of hydrogen gas is 0.04m 3 / h, argon gas flow rate 0.01m 3 / h. Take it out after 20 hours of deposition, turn it over and deposit it for another 20 hours. Increase the deposition ...

Embodiment 2

[0037] The carbon / carbon sample is pretreated first. Choose a density of 1.70g / cm 3 After polishing the C / C composite material with 120# and 400# silicon carbide sandpaper, ultrasonically oscillate in distilled water for 30 minutes, and then rinse repeatedly with distilled water; dry the cleaned carbon / carbon composite material at 120°C for 24 hours for later use .

[0038] Deposit a silicon carbide coating. The carbon / carbon sample after the above treatment is placed in a graphite crucible and placed in a chemical vapor deposition furnace for silicon carbide deposition. Small holes are drilled at the bottom of the graphite crucible to ensure gas circulation. The deposition temperature is 1200°C, the deposition pressure is 10mmHg, the flow rate of trichloromethylsilane (MTS) is 140g / h, and the flow rate of hydrogen gas is 0.16m 3 / h, argon flow rate 0.05m 3 / h. Take it out after 12 hours of deposition, turn it over and deposit it for another 12 hours. Co-deposition 4 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com