A humanoid automatic palletizing device for automobile glass

A technology for automotive glass and palletizing devices, applied in transportation and packaging, program control manipulators, furnaces, etc., can solve the problems of lack of mechanization, large floor space, and reduced glass qualification rate, and achieve novel structure, simple structure, Realize the effect of motion planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

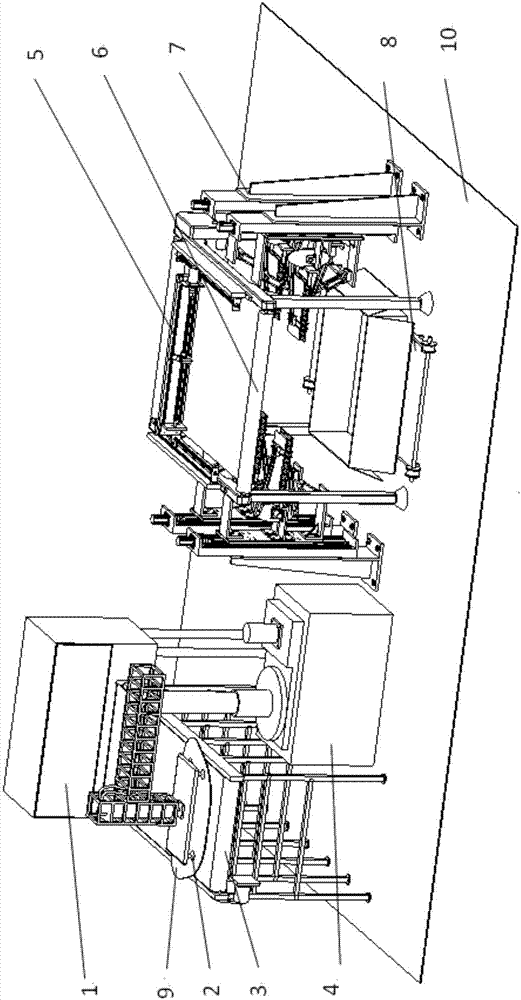

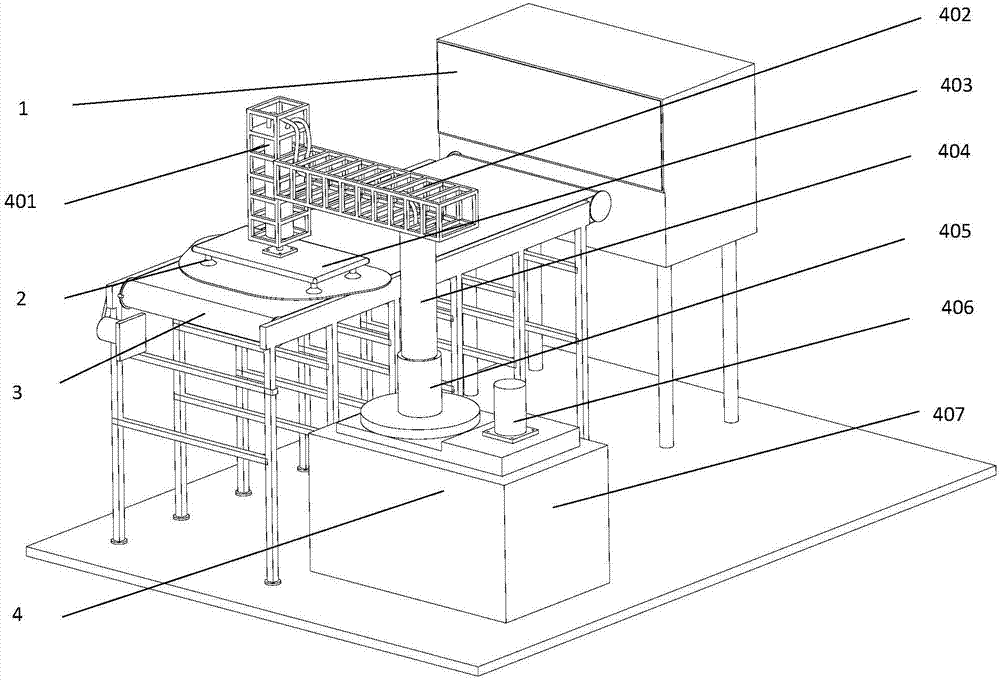

[0026] The discharge box 1 is fixedly installed on the bottom plate 10, the extruding exhaust type pick-up hand 2 is fixedly connected with the rotary mechanism 4, the glass conveyor belt 3 is fixedly installed on the bottom plate 10, the glass cutting device 5 is fixedly connected with the paper stick device 6, and the paper stick device 6 is fixedly connected. The stick device 6 is fixedly installed on the base plate 10, the humanoid manipulator mechanism 7 is fixedly connected with the base plate 10, and two groups of two pieces are installed in parallel on both sides of the paper stick device 6, so as to realize the stable clamping of the automobile glass; The conveyor belt device 8 is placed directly below the paper stick device 6 , and the packing case conveyor belt device 8 is fixedly connected to the bottom plate 10 .

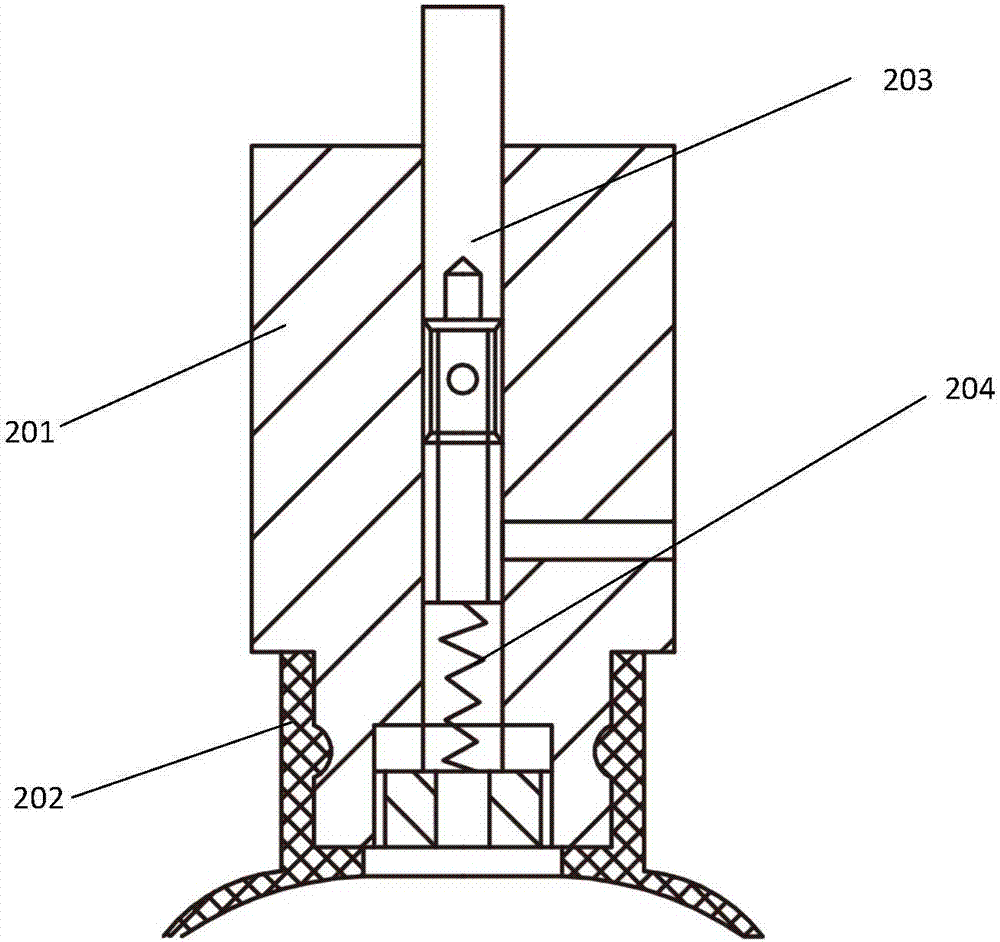

[0027] The structure of the extruding exhaust type material retrieving hand 2 described in the present invention is: comprise shell 201, rubber sucker 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com