Automatic automobile waxing machine

An automatic and automotive technology, applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc., can solve the problems of different thickness of wax on the car body, affect the appearance of the car body, wax melting or condensation, etc., to improve the appearance of waxing performance, improved waxing efficiency, consistent waxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

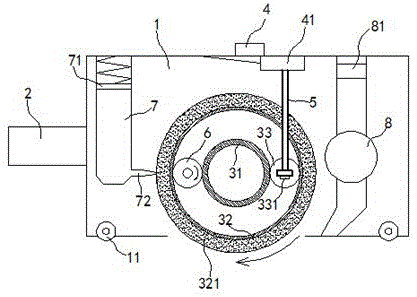

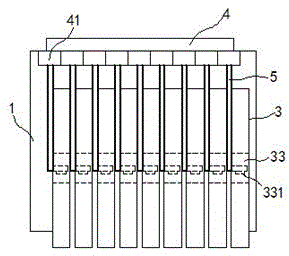

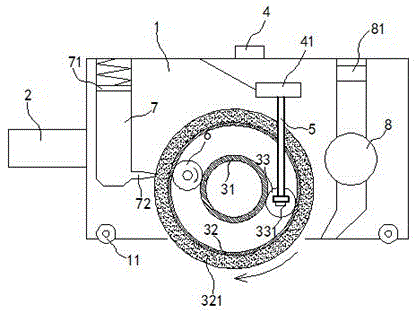

[0019] exist Figure 1 to Figure 4 In the shown embodiment, the automobile automatic waxing machine includes a housing 1 and a handle 2, and the handle 2 is fixedly mounted on the side wall of the housing 1; Wheel 3, described waxing wheel 3 coaxial, parallel arrangement; Described waxing wheel 3 comprises inner wheel 31, outer wheel 32 and transmission wheel 33, and described inner wheel 31 and outer wheel 32 are concentric structures, and described transmission The wheel 33 is located between the inner wheel 31 and the outer wheel 32, and is tangent to the inner wheel 31 and the outer wheel 32; a waxing sponge 321 is fixedly adhered to the outer peripheral surface of the outer wheel 32; A distance sensor 331; a controller 4 is installed on the housing 1, and each distance sensor 331 is electrically connected to the controller 4; the controller 4 includes a controller corresponding to each waxing wheel 3 end 41, a transmission rod 5 is also installed on each of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com