Cable striping pincers and stripping method therefor

A cable and pliers body technology, applied in the field of cable stripping pliers and stripping, can solve the problems of inability to achieve axial stripping, unadjustable axial length, and inability to strip cables, and achieve simple structure and method, strong versatility, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

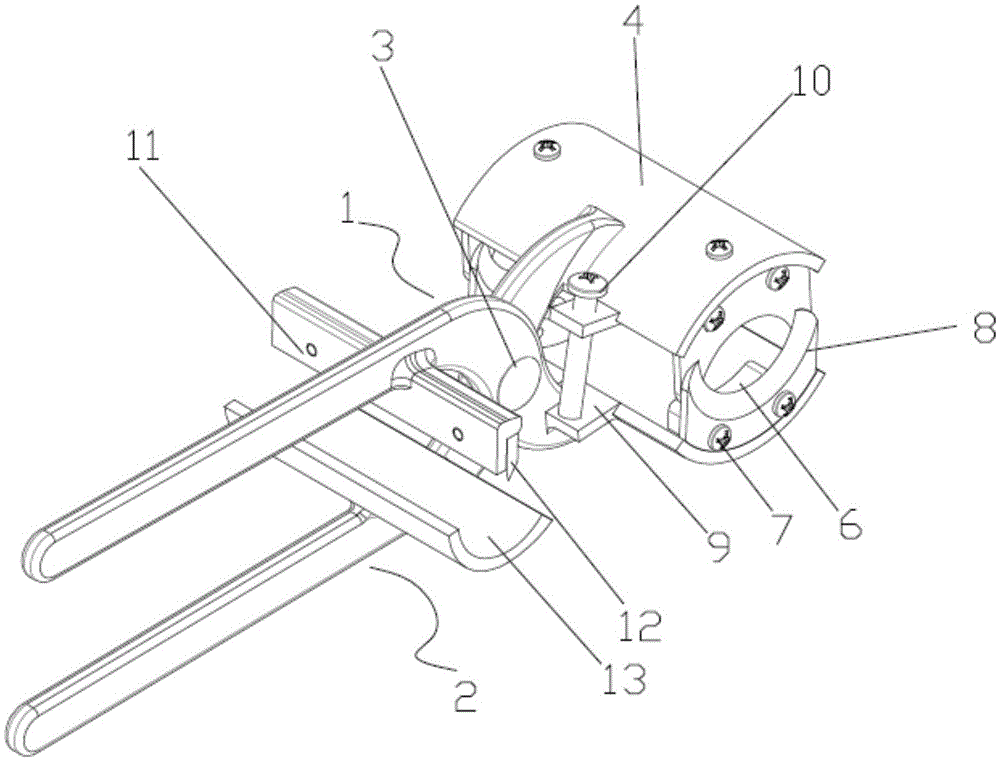

[0041] like figure 1 As shown, a cable stripping pliers includes an upper pliers body 1 and a lower pliers body 2 hinged through a pin shaft 3, and a pliers head is respectively formed at the front end of the hinge point of the upper pliers body 1 and the lower pliers body 2, and at the hinge point A pliers handle is formed at the rear end of the pliers respectively, and a transverse blade 12 for axial peeling is fixed on the upper pliers body 1 or the lower pliers body 2 .

[0042] Wherein, a transverse blade 12 for axial peeling is fixed on the inner side of the forceps head of the upper forceps body 1 or the inner side of the forceps head of the lower forceps body 2, and the inner side of the forceps handle of the upper forceps body 1 and the forceps handle of the lower forceps body 2 are fixed A vertical blade 8 for circumferentially peeling the cable is fixed on the inner side, and the vertical blade 8 fixed on the clamp handle of the upper clamp body 1 and the vertical b...

Embodiment 2

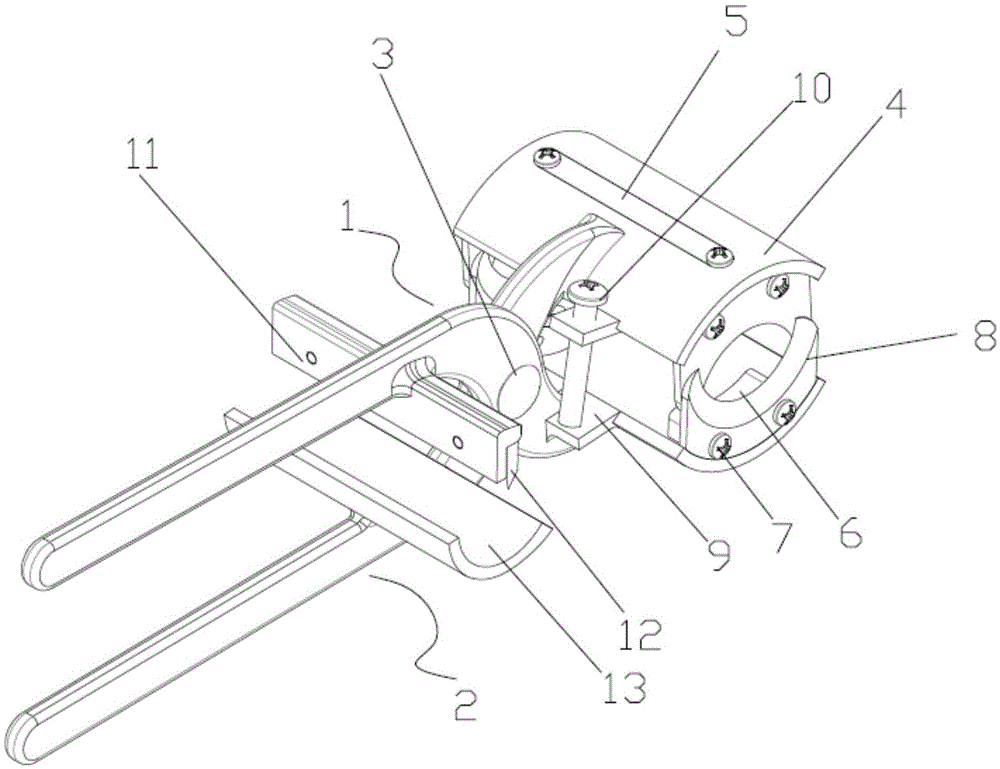

[0057] like figure 2 As shown, this embodiment adds an axial peeling length adjustment structure of the vertical blade 8 on the basis of the first embodiment. The fixing bolts 7 of 5 are fixed on the connecting piece 4 on the corresponding pliers body in the upper pliers body 1 and the lower pliers body 2, and the connecting block 6 can slide on the connecting piece 4 along the length direction of the guide groove to adjust the connecting piece 4. The distance between the two connecting blocks 6 can be adjusted to realize the peeling length.

Embodiment 3

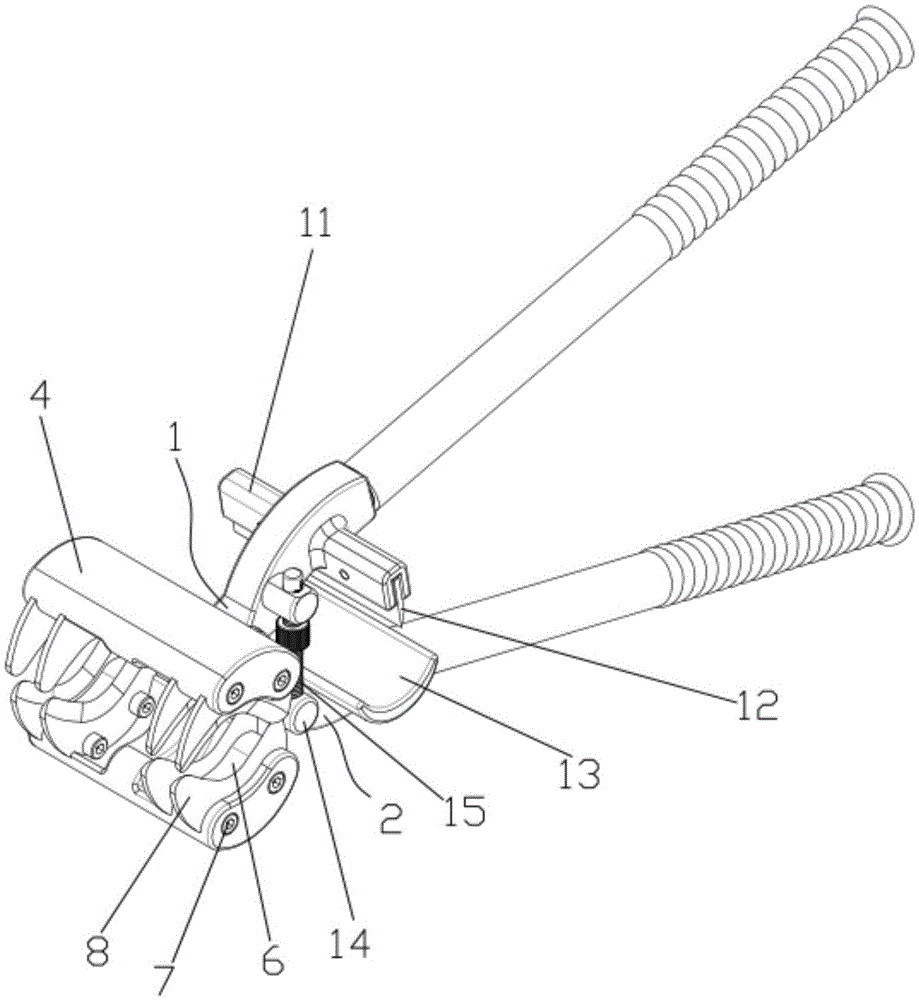

[0059] like image 3 As shown, this embodiment is provided with an axial peeling length adjustment structure that is different from the vertical blade in Example 2. The adjustment structure includes that a plurality of vertical blades 8 corresponding to each other are arranged on the connecting block 6, so that the peeling length can be adjusted. tune.

[0060] like image 3 As shown in the figure, this embodiment is provided with a peeling depth adjustment structure that is different from that in Embodiment 1 and Embodiment 2. The adjustment structure includes that both the upper jaw body 1 and the lower jaw body 2 are provided with A cylinder 14 with a threaded hole, and at least one cylinder 14 is hinged with the pliers head on which the cylinder 14 is provided, or a cylinder with a threaded hole is provided on the pliers handle of the upper pliers body 1 and the pliers handle of the lower pliers body 2 14, and at least one cylinder 14 is hinged with the clamp handle on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com