Flexible liquid crystal display panel and display device

A flexible liquid crystal display and panel technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage and non-perpendicularity of flexible liquid crystal display panels, and achieve the effect of improving the problem of dark state light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

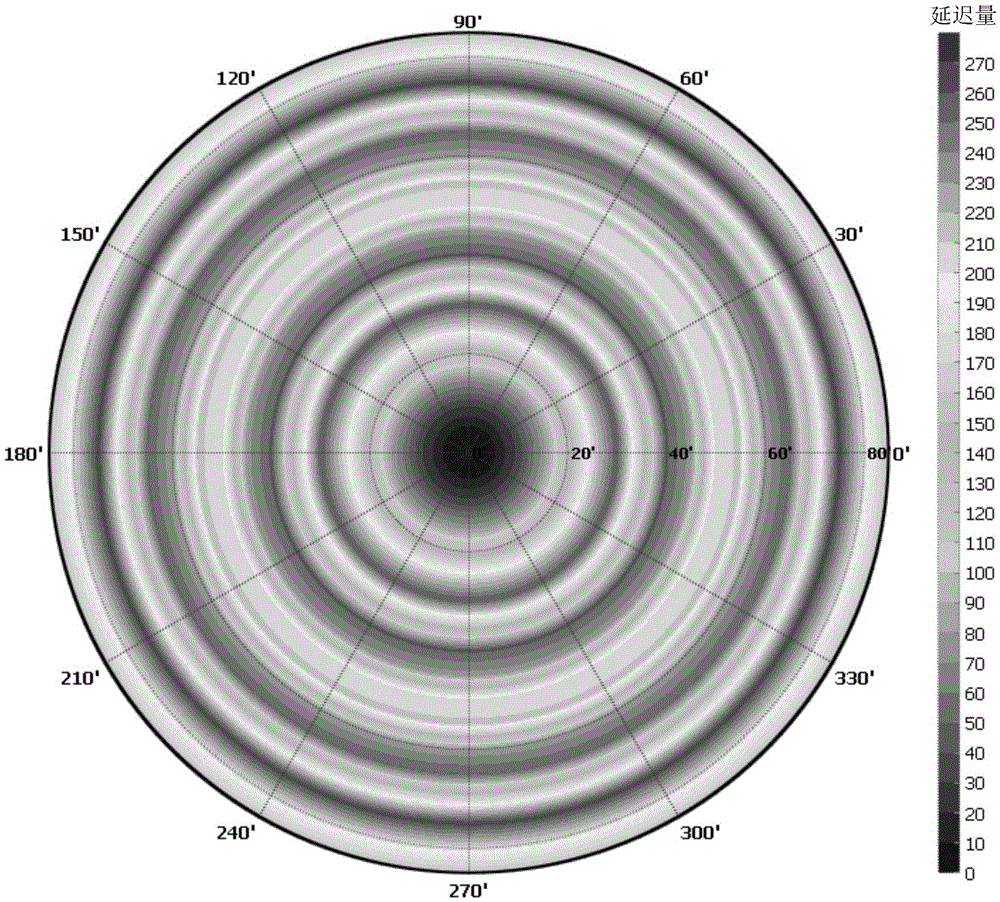

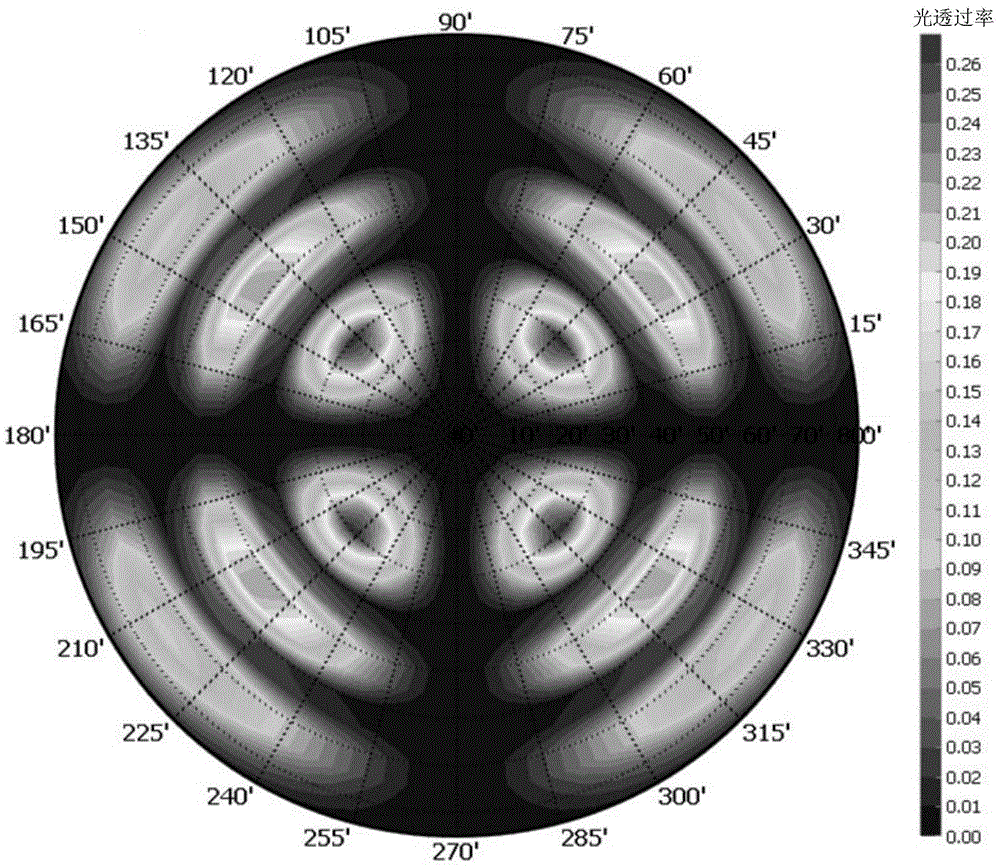

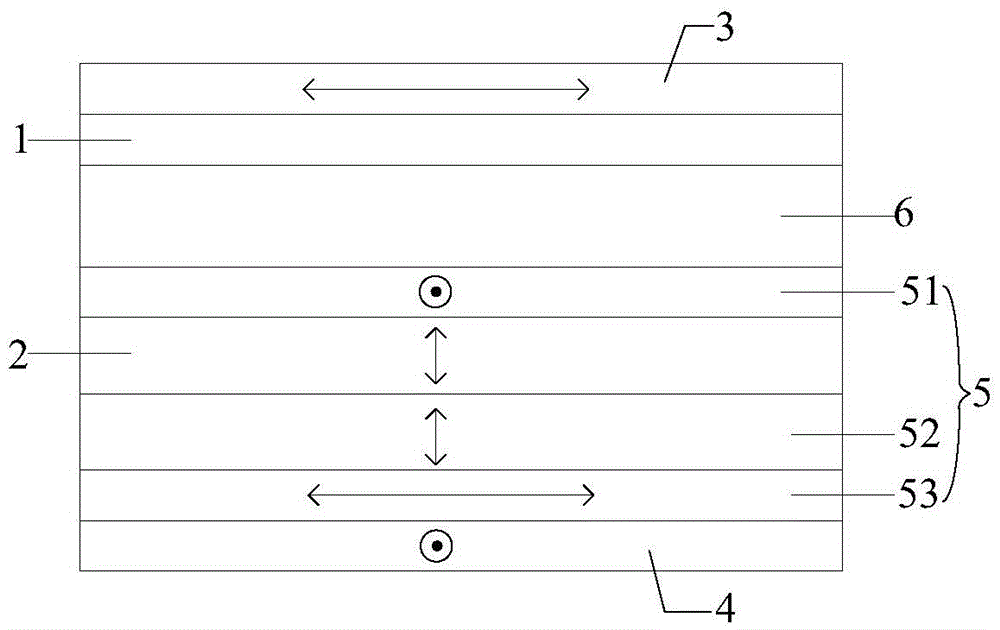

[0055] Example 1: If Figure 3a As shown, the compensation film 5 includes: a first compensation film 51 located between the second flexible substrate 2 and the liquid crystal cell 6, and a second flexible substrate 2 located between the second polarizer 4 and on the second flexible substrate 2 The second compensation film 52 and the third compensation film 53 are sequentially stacked on the top; wherein, the optical axis of the first compensation film 51 and the light absorption axis of the second polarizer 4 are parallel to each other, which is equivalent to an -Aplate; the first compensation film 51 The range of the retardation Ro of the plane where the second compensation film 52 is located is -80nm to -100nm; the optical axis of the second compensation film 52 is perpendicular to the second flexible substrate 2, which is equivalent to a +Cplate; the retardation of the plane where the second compensation film 52 is located The range of Ro is 2320nm to 2380nm; the optical a...

example 2

[0063] Example 2: If Figure 4a As shown, the compensation film 5 includes: a first compensation film 51 and a second compensation film 52 that are sequentially stacked between the second flexible substrate 2 and the second polarizer 4 and arranged on the second flexible substrate 2; The optical axis of a compensation film 51 is perpendicular to the second flexible substrate 2, which is equivalent to a +Cplate; the retardation Ro of the plane where the first compensation film 51 is located ranges from 2360nm to 2440nm; the optical axis of the second compensation film 52 and The light absorption axes of the first polarizer 3 are parallel to each other, corresponding to an -Aplate; the retardation Ro of the plane where the second compensation film 52 is located ranges from -120nm to -150nm. It should be noted that the optical axis of the second flexible substrate 2 is perpendicular to its surface, and the retardation of its plane is Ro=0nm.

[0064] In specific implementation, ...

example 3

[0070] Example 3: If Figure 5a As shown, the compensation film 5 includes: a first compensation film 51 and a second compensation film 52 that are sequentially stacked between the second flexible substrate 2 and the liquid crystal cell 6 and arranged on the second flexible substrate 2; wherein, the first compensation film The optical axis of the film 51 is perpendicular to the second flexible substrate 2, which is equivalent to a +Cplate; the retardation Ro of the plane where the first compensation film 51 is located ranges from 2400nm to 2450nm; the optical axis of the second compensation film 52 and the second The light absorption axes of the polarizers 4 are parallel to each other, corresponding to an -Aplate; the retardation Ro of the plane where the second compensation film 52 is located ranges from -120nm to -160nm. It should be noted that the optical axis of the second flexible substrate 2 is perpendicular to its surface, and the retardation of its plane is Ro=0nm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amount of delay | aaaaa | aaaaa |

| Amount of delay | aaaaa | aaaaa |

| Amount of delay | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com