Anti-seismic anchor bolt

An anti-seismic anchor and screw technology, applied in the direction of connecting components, pins, mechanical equipment, etc., to achieve the effect of easy popularization and application, good practicability and reasonable overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings.

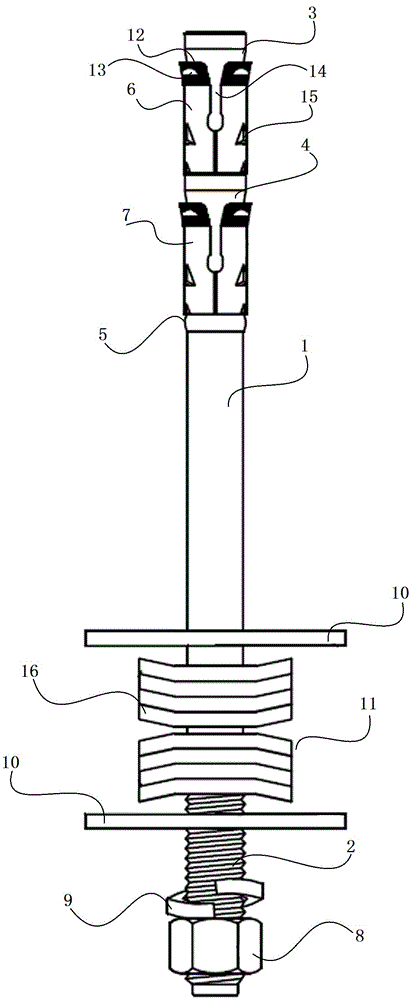

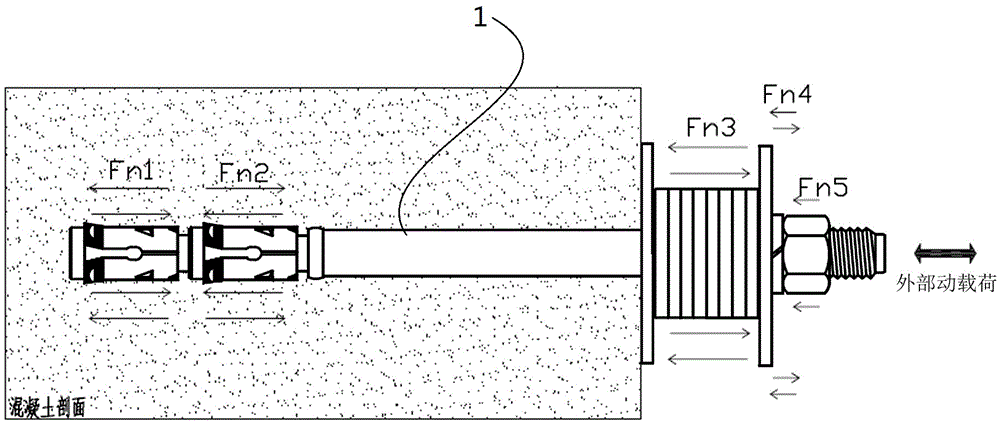

[0026] The invention discloses an anti-seismic anchor bolt, which is different from the prior art in that it includes a double-shrink screw 1, an external thread 2 is formed on the wall of one end of the double-shrink screw 1, and the other side of the double-shrink screw 1 One end is sequentially provided with a first conical flange 3, a second conical flange 4, an annular flange 5, a first conical flange 3 and a second conical flange along the wall of the double shrinkage screw from the end. The rod wall between 4 is covered with a first strong friction plate 6, and the second strong friction plate 7 is sleeved between the second tapered flange 4 and the annular flange 5. The external thread 2 at one end of the above-mentioned double shrinkage screw 1 There is at least one nut 8 screwed on at least one nut 8, and a spring washer 9 is sleeved on the double shrinkage scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com