Electric auxiliary pressurization system and application method thereof

A supercharging system and electric auxiliary technology, applied in the direction of charging system, engine components, combustion engine, etc., can solve the problems of weak supercharging effect and difficult installation, achieve strong supercharging effect, small installation difficulty, solve magnetic effect of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

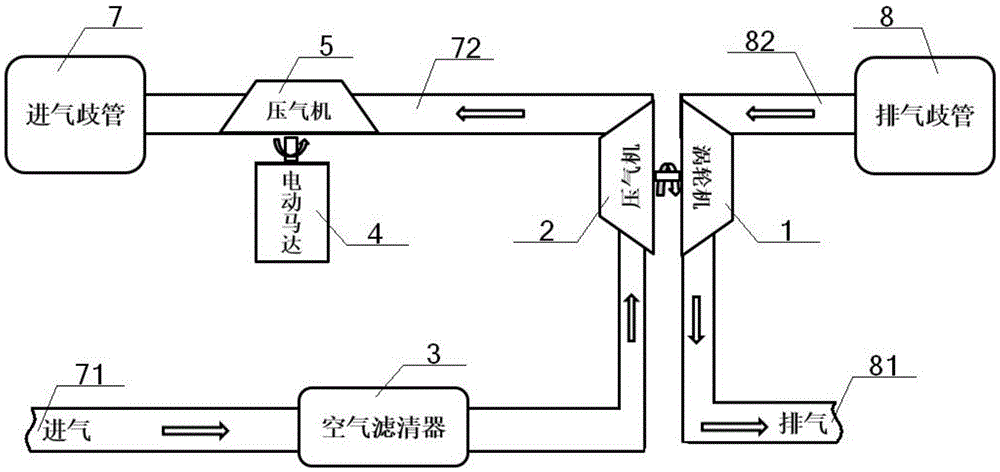

[0050] see figure 1 and figure 2 :

[0051] Structurally: an electric auxiliary supercharging system, including an exhaust gas turbine 1, an exhaust gas compressor 2, an air filter 3, an electric motor 4 and an auxiliary compressor 5, the output end of the electric motor 4 is connected to the auxiliary compressor 5 The driving shaft of the impeller is connected, and one end of the air filter 3 communicates with the air inlet 71, and the other end successively passes through the impeller air channel in the exhaust compressor 2 and the impeller air channel in the auxiliary compressor 5, and then connects with the air intake port. The gas manifold 7 communicates, the impeller in the exhaust gas compressor 2 is coaxially connected with the turbine in the exhaust gas turbine 1, the inlet port of the turbine air passage in the exhaust gas turbine 1 communicates with the exhaust manifold 8, and the gas outlet communicates with the exhaust gas exhaust port 81 are connected.

[005...

Embodiment 2

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] Structurally: a pressure sensor 61 is arranged on the position between the intake manifold 7 and the auxiliary compressor 5 in the intake passage 72, the output end of the pressure sensor 61 is connected to the input end signal of the ECU6, and the output end of the ECU6 Terminal is connected with the input signal of electric motor 4.

[0056] On the method: the pressure value in the air inlet 72 is measured by the pressure sensor 61, and the measured value is transmitted to the ECU6 immediately; the operation of the electric motor 4 driving the auxiliary compressor 5 means that the ECU6 controls the electric motor 4 to Driving the auxiliary compressor 5 to run; the electric motor 4 and the auxiliary compressor 5 to stop running means that the ECU 6 controls the electric motor 4 to stop running so that the auxiliary compressor 5 stops running.

Embodiment 3

[0058] Basic content is the same as embodiment 2, the difference is:

[0059] Structurally: the output end of the electric motor 4 is connected with the drive shaft of the impeller in the auxiliary compressor 5 through the electromagnetic clutch 42 . The electromagnetic clutch 42 is preferably a multi-disc electromagnetic clutch.

[0060] In terms of method: the ECU6 controls the electric motor 4 to drive the auxiliary compressor 5 to run, which means: the ECU6 controls the electromagnetic clutch 42 to close to conduct the electric motor 4 and the auxiliary compressor 5, thereby driving the auxiliary compressor 5 to run; the ECU6 controls The stopping of the electric motor 4 means that the ECU 6 controls the electromagnetic clutch 42 to disconnect, and the electric motor 4 and the auxiliary compressor 5 stop running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com