A Component Curtain Wall System Suitable for Dry Construction

A curtain wall and component technology, applied in the field of component curtain wall system, can solve the problem of difficult replacement, and achieve the effect of good waterproof and energy saving performance, convenient material selection and production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

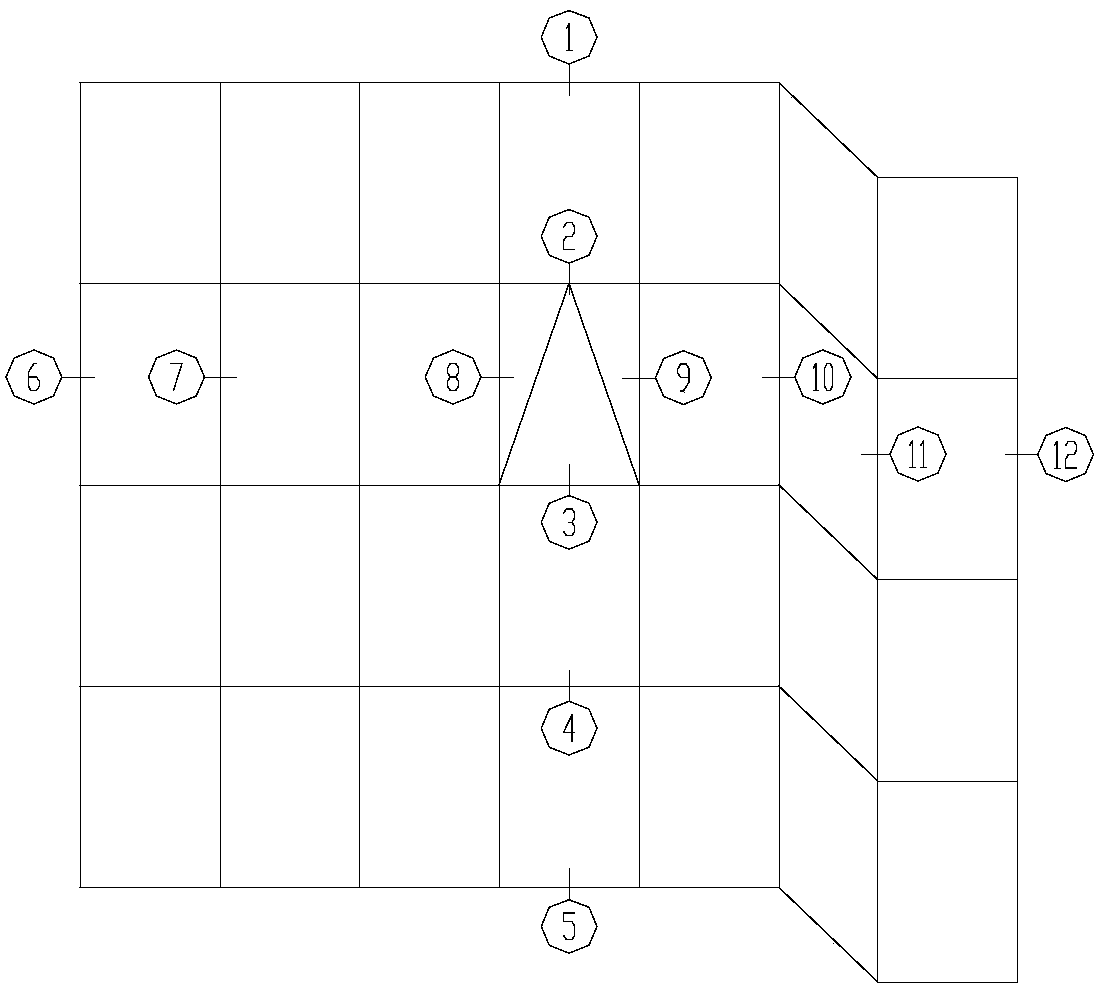

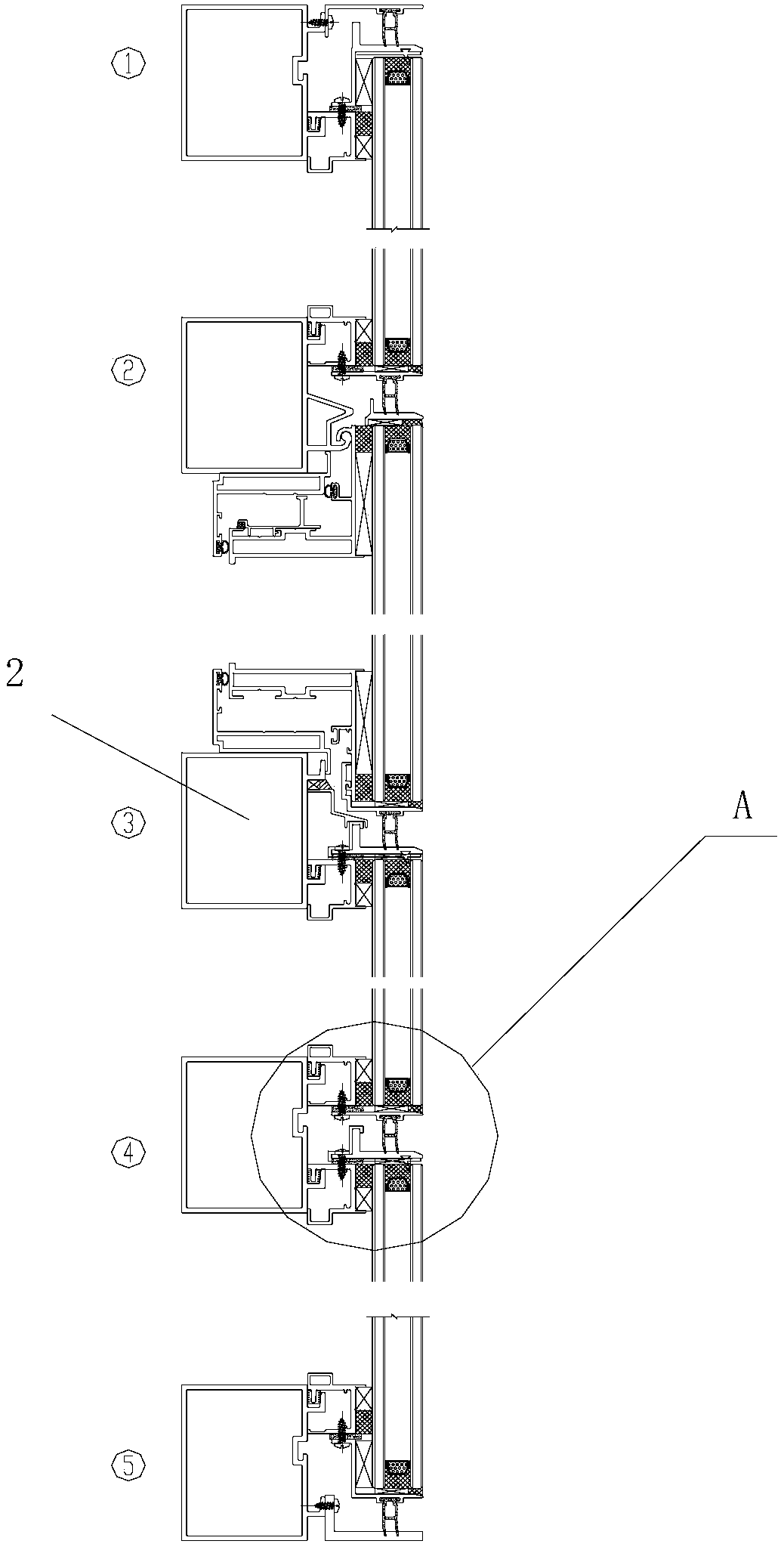

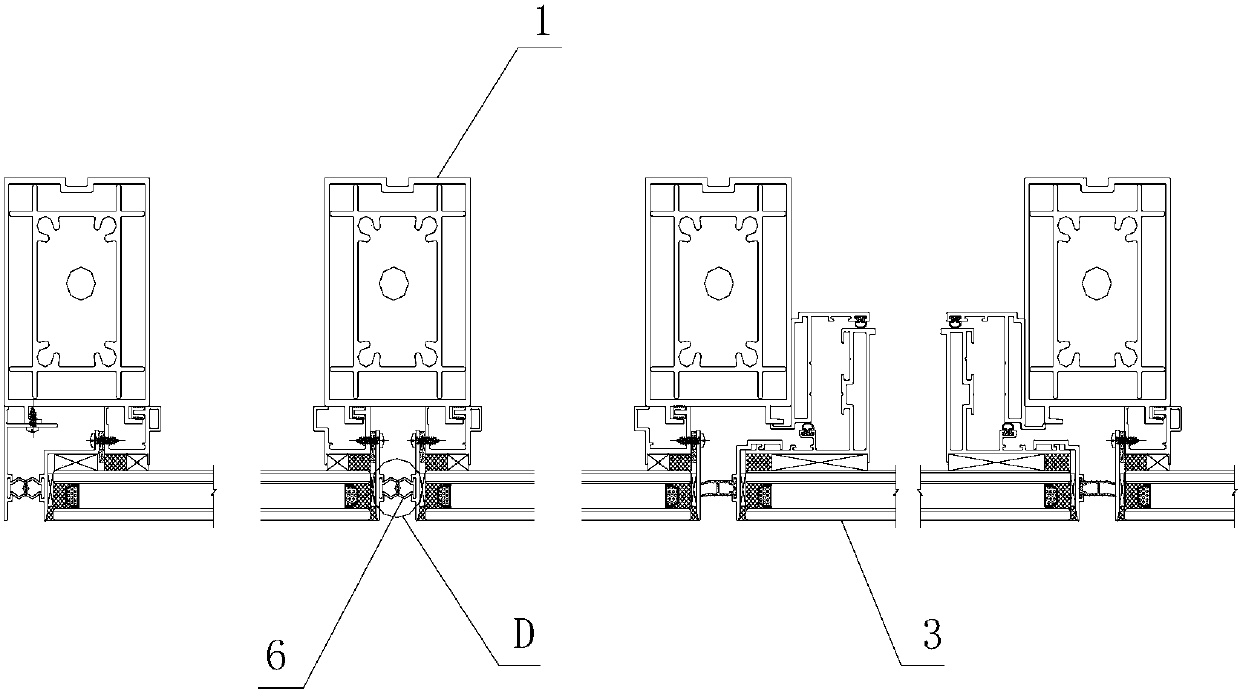

[0049] Such as Figure 1-Figure 8 As shown, a constructive curtain wall system suitable for dry construction includes: a column 1, a beam 2 connected to the column 1, and a panel 3 installed on the column 1 and the beam 2; in the longitudinal gap formed by the panel 3 There are several interface auxiliary materials 4 and a plurality of first sealing strips 6, the first sealing strips 6 are installed between two adjacent interface auxiliary materials 4, and a water retaining strip 9 is arranged on the top of each panel 3, and each panel 3 is provided with a second sealing strip 10; it is characterized in that the interface auxiliary material 4 is installed across the top of the adjacent two panels 3 to cut off the longitudinal gap, and the two ends of the interface auxiliary material 4 are inserted into the water retaining strip 9 The end portion of the interface auxiliary material 4 is also provided with a sealing layer 5 that is sealingly connected with the end of the water r...

Embodiment 2

[0061] Such as Figure 9 As shown, this embodiment provides a constructional curtain wall system suitable for dry construction, which is basically the same as Embodiment 1, the difference lies in:

[0062] 1. An exposed frame 11 is installed corresponding to the horizontal gap of the curtain wall, forming a semi-exposed frame curtain wall system with horizontal and vertical concealment.

[0063] 2. The left and right rubber strips are pre-installed on the left and right sides of each panel, and the second sealing strip is pre-installed on the lower side of each panel, and the ends of the second sealing strip are attached to the sides of the left and right sealing strips. In this way, when the bearing structure is formed, the left and right rubber strips of the adjacent two panels are closely attached to each other to form the first sealing strips, so that the bearing structure and the first sealing strips are assembled at the same time, and the installation is extremely conven...

Embodiment 3

[0065] Such as Figure 10 As shown, this embodiment provides a constructive curtain wall system suitable for dry construction, which is basically the same as that of Embodiment 1, the difference is that a bright frame 12 is installed in the longitudinal gap corresponding to the curtain wall, forming a vertically bright and horizontally concealed semi-blind Frame curtain wall system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com