Special tool for maintenance of corrugated beam barrier of highway

A technology of wave beam guardrails and special tools, which is applied in the fields of line shape adjustment and rebound prevention tools, guardrail plate handling, load-bearing bolt installation, highway wave beam guardrail maintenance, and can solve the problems of the end of the guardrail 4 bouncing, hurting people, Large deformation elastic stress and other problems, to achieve the effect of reducing construction safety hazards, reducing labor intensity, and reducing force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

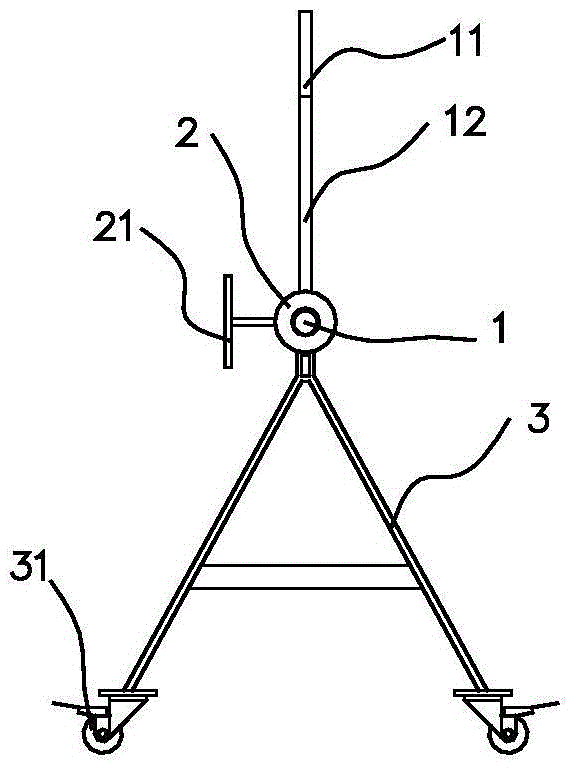

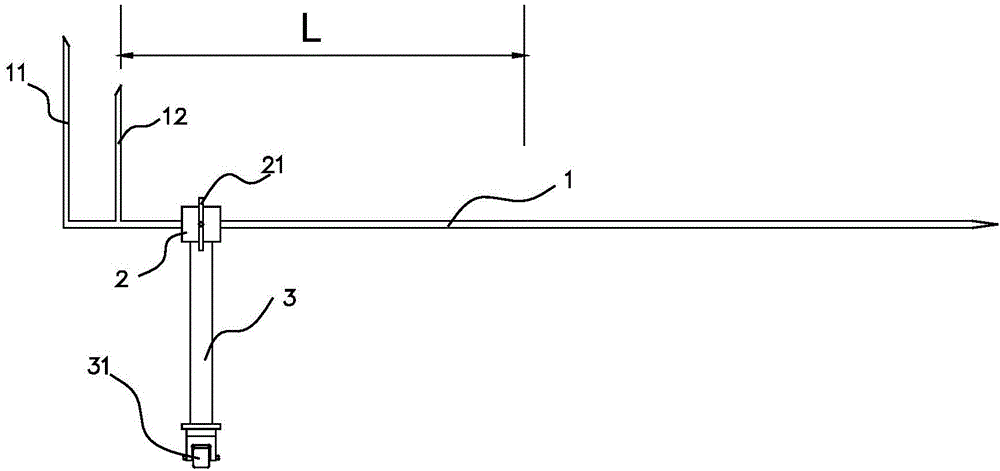

[0028] A. If figure 1 As shown, the movable support structure 2 is a collar structure, the bottom end of the collar is fixedly connected to the top of the walking bracket 3, and the inner diameter of the collar is 1.1-1.5 times the diameter of the main rod 1; The axial length of the collar is 1.1-3.0 times the inner diameter of the collar. This can not only ensure the axial adjustment of the position of the main rod 1 relative to the collar, but also ensure that the main rod can perform a prying action therein.

[0029] A stop screw 21 is provided on the ring wall of the collar for locking the main rod 1 .

[0030] B. If image 3 As shown, the movable support structure is a U-shaped groove structure block, and the bottom end of the U-shaped groove structure block is fixedly connected to the top of the walking bracket. The groove width of the U-shaped groove structure block is 1 / 2 of the diameter of the main rod 1.1-1.5 times; the axial length of the U-shaped groove structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com