The Method of Accurately Filling High Polymers in Road Basic Diseases for Road Restoration

A road base and road repair technology, applied in road repair, roads, roads, etc., can solve the problems of time-consuming, labor-intensive excavation and filling, long-term safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

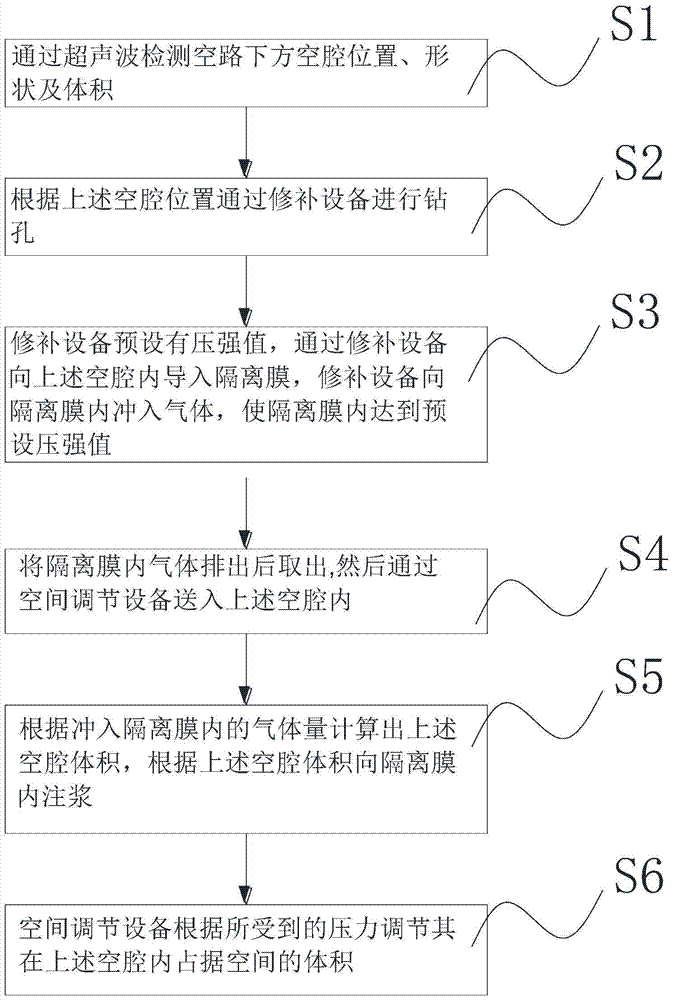

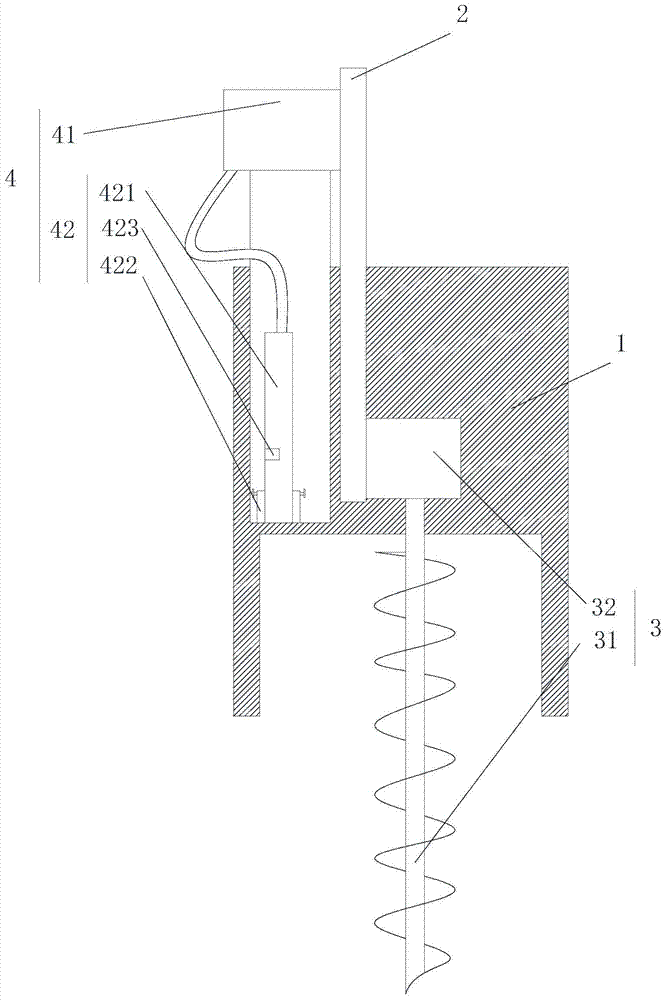

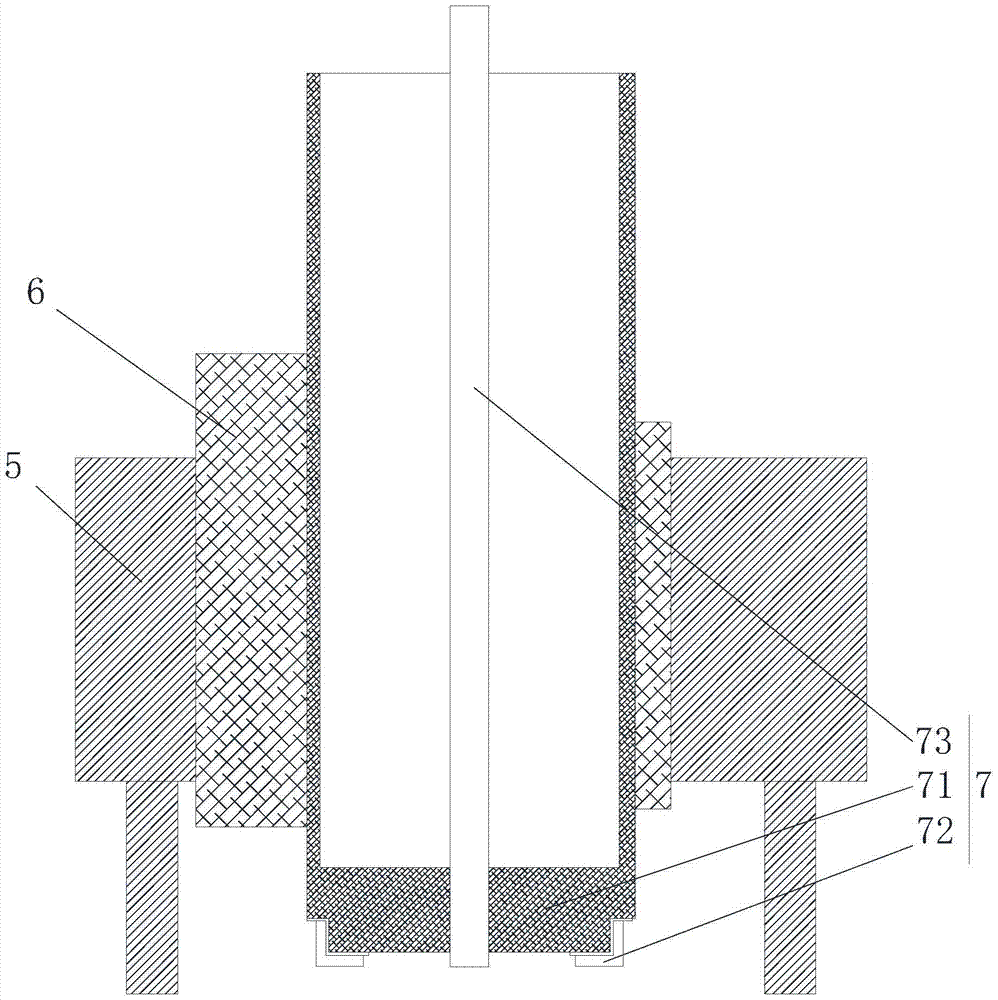

[0028] refer to figure 1 , figure 2 , image 3 and Figure 4 Shown, the method that the present invention proposes accurately filling high polymer to carry out road repair at road base disease place, comprises the following steps:

[0029] S1. Detect the position, shape and volume of the cavity below the air passage through ultrasonic waves.

[0030] S2. Drill holes with repairing equipment according to the position of the above cavity.

[0031] The repairing equipment includes a frame 1, a rotating shaft 2, a drilling mechanism 3 and an inflation mechanism 4;

[0032] The rotating shaft 2 is rotatably installed on the frame 1.

[0033] Drilling mechanism 3 comprises drilling part 31 and first driving device 32, and drilling part 31 can select screw rod for use, and screw rod facilitates earth discharge while effectively drilling, and first driving device 32 moves and is installed on the rotating shaft 2, the second A driving device 32 drives the screw rod to rotate; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com