Bipolar membrane device for preparing amino-1-propanol

An aminopropanol, bipolar membrane technology, applied in the field of membrane separation, can solve the problems of unsafe production, short electrode life, rising production costs, etc., and achieve the effects of reducing equipment investment costs, improving processing capacity, and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

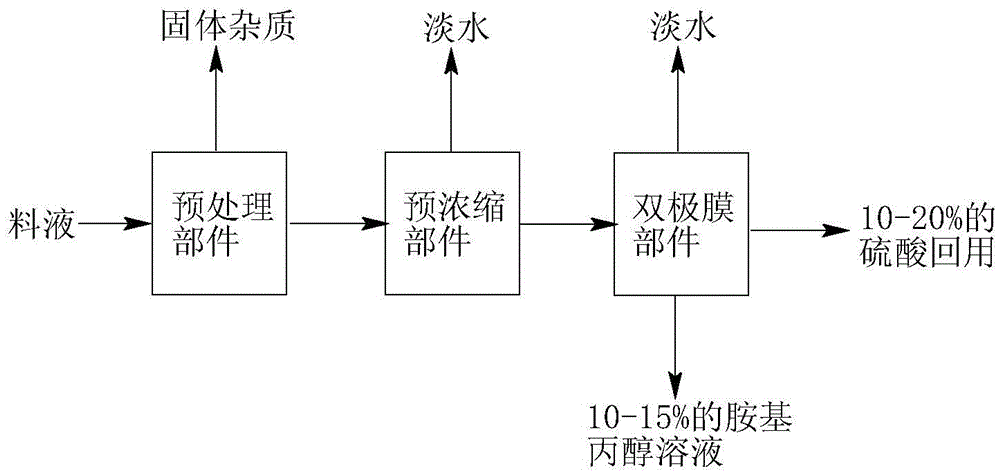

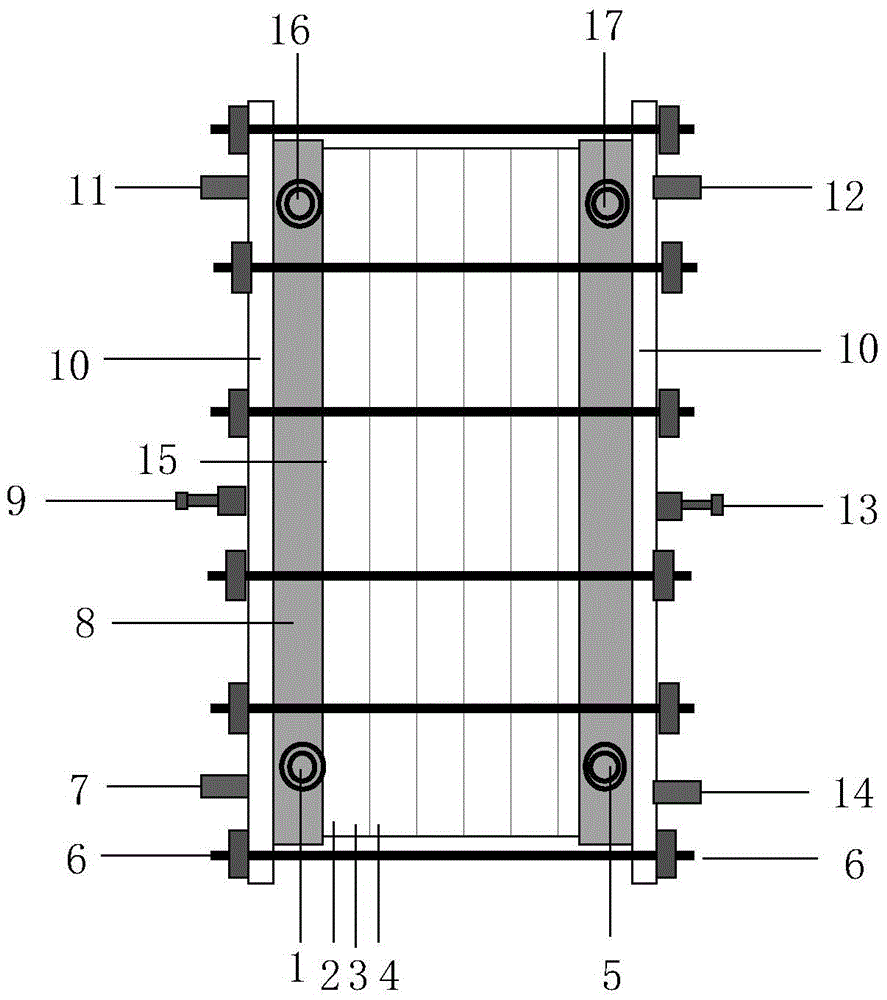

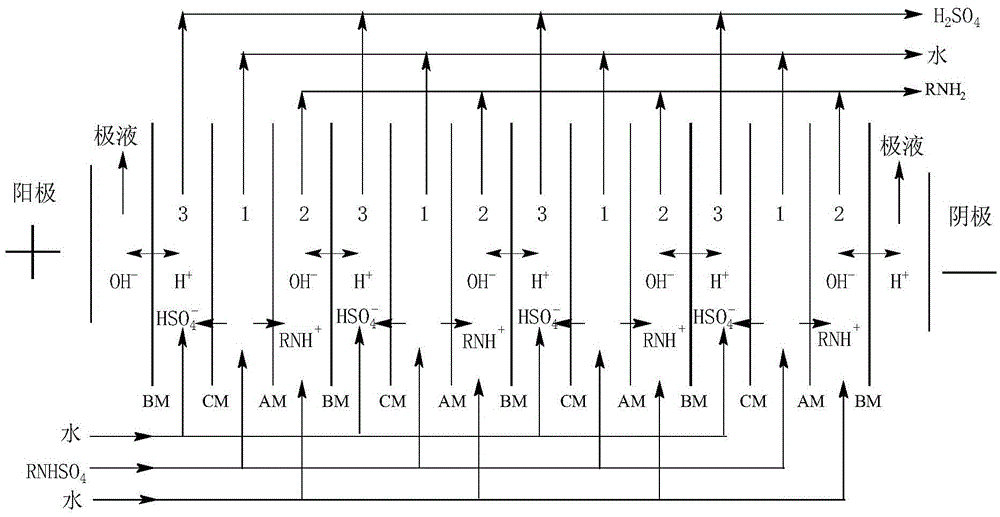

[0034] according to figure 1 , figure 2 , image 3 As shown, a set of bipolar membrane device for preparing aminopropanol is installed, including a pretreatment component, a preconcentration component, and a bipolar membrane component. The bipolar membrane components include acid-resistant electrodes, strong acid-resistant and aminopropanol-resistant bipolar membranes, strong alkali-resistant positive membranes for alkali resistance, and strong acid-resistant acid-resistant negative membranes. Among them, the pretreatment part adopts micro-ultrafiltration membrane of polytetrafluoroethylene; the pre-concentration part adopts homogeneous membrane electrodialysis prepared by impregnation method; the size of bipolar membrane part adopts 400*800mm, and the thickness of acid-resistant electrode platinum primer is 1 micron , the mass ratio of tantalum oxide, iridium oxide, and ruthenium oxide is 2:3:5; the sintering temperature is 800°C, and the sintering time is 4 hours each tim...

Embodiment 2

[0038] according to figure 1 , figure 2 , image 3 As shown, a set of bipolar membrane device for preparing aminopropanol is installed, including a pretreatment component, a preconcentration component, and a bipolar membrane component. The bipolar membrane components include acid-resistant electrodes, strong acid-resistant and aminopropanol-resistant bipolar membranes, strong alkali-resistant positive membranes for alkali resistance, and strong acid-resistant acid-resistant negative membranes. Among them, the pretreatment part adopts micro-ultrafiltration membrane of polytetrafluoroethylene; the pre-concentration part adopts homogeneous membrane electrodialysis prepared by impregnation method; the size of bipolar membrane part adopts 400*800mm, and the thickness of acid-resistant electrode platinum primer is 1 micron , the mass ratio of tantalum oxide, iridium oxide, and ruthenium oxide is 1:2:1; the sintering temperature is 750°C, and the sintering time is 3 hours each tim...

Embodiment 3

[0042] according to figure 1 , figure 2 , image 3 As shown, a set of bipolar membrane device for preparing aminopropanol is installed, including a pretreatment component, a preconcentration component, and a bipolar membrane component. The bipolar membrane components include acid-resistant electrodes, strong acid-resistant and aminopropanol-resistant bipolar membranes, strong alkali-resistant positive membranes for alkali resistance, and strong acid-resistant acid-resistant negative membranes. Among them, the pretreatment part adopts micro-ultrafiltration membrane of polytetrafluoroethylene; the pre-concentration part adopts homogeneous membrane electrodialysis prepared by impregnation method; the size of bipolar membrane part adopts 600*1200mm, and the thickness of acid-resistant electrode platinum primer is 1 micron , the mass ratio of tantalum oxide, iridium oxide, and ruthenium oxide is 3:2:5; the sintering temperature is 850°C, and the sintering time is 5 hours each ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Membrane resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com