High salinity wastewater zero-emission method

A high-salt wastewater and zero-discharge technology is applied in energy wastewater treatment, chemical instruments and methods, and multi-stage water/sewage treatment. Low operating cost and effective solution to difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

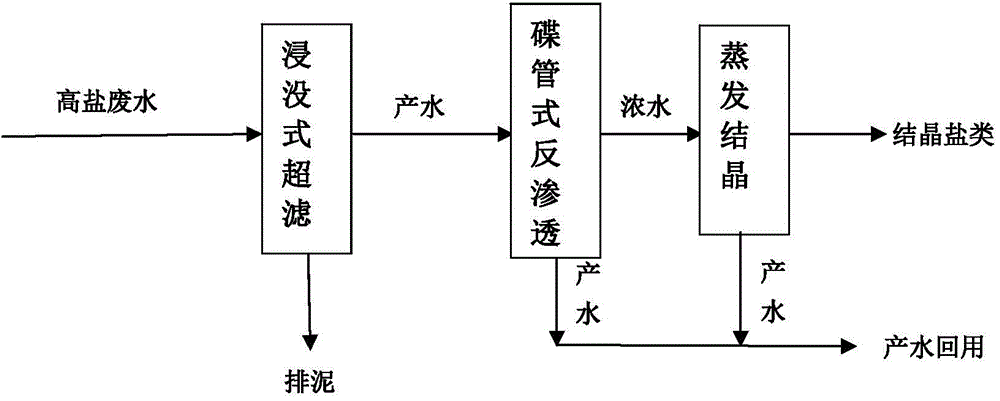

[0066] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt wastewater in this example are: wastewater pH6.5, conductivity 10000μs / cm, COD cr 0 mg / L, Na + 2000mg / L, Cl - 2500mg / L, total hardness (CaCO 3 )100mg / L, SS500mg / L, dissolved silicon 50mg / L, NH 4 -N50mg / L.

[0067] Adopt the zero discharge method of high-salt wastewater of the present invention to process the steps of high-salt wastewater as follows:

[0068] (1) Submerged ultrafiltration: High-salt wastewater enters the submerged ultrafiltration unit for filtration treatment to remove most of the turbidity and suspended solids in the high-salt wastewater. After being separated by the submerged ultrafiltration unit, the obtained ultrafiltration product Water enters step (2) for treatment, and the submerged ultrafiltration system regularly discharges sludge, and the discharged sludge is dried and disposed of;

[0069] (2) Disk-type reverse osmosis: The ultrafiltrat...

Embodiment 2

[0082] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt wastewater in this example are: wastewater pH 7, conductivity 15000 μs / cm, COD cr 50mg / L, Na + 3000mg / L, Cl - 3500mg / L, total hardness (CaCO 3 )500mg / L, SS700mg / L, dissolved silicon 70mg / L, NH 4 -N200mg / L.

[0083] The operating steps of embodiment 2 are the same as embodiment 1, and the differences between this embodiment and embodiment 1 are:

[0084] In the above steps, the submerged ultrafiltration unit in step (1) adopts an external pressure type, submerged polysulfone hollow fiber curtain membrane module with a membrane pore size of 0.03 μm;

[0085] In the above steps, the aeration system at the bottom of the submerged ultrafiltration tank of the submerged ultrafiltration unit in step (1) adopts aeration tube aeration, adopts an air compressor to generate compressed air, and the air-to-water volume ratio is 15:1;

[0086] In the above steps, the operating ...

Embodiment 3

[0095] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt wastewater in this example are: wastewater pH 7.5, conductivity 20000 μs / cm, COD cr 100mg / L, Na + 4000mg / L, Cl - 5000mg / L, total hardness (CaCO 3 )1000mg / L, SS1000mg / L, dissolved silicon 100mg / L, NH 4 -N500mg / L.

[0096] The operating steps of embodiment 3 are the same as embodiment 1, and the differences between this embodiment and embodiment 1 are:

[0097] In the above steps, the submerged ultrafiltration unit in step (1) adopts an external pressure type, submerged polytetrafluoroethylene hollow fiber curtain membrane module, and the membrane pore size is 0.05 μm;

[0098] In the above-mentioned steps, the aeration system at the bottom of the submerged ultrafiltration tank of the submerged ultrafiltration unit in step (1) adopts aeration disc aeration, adopts an air compressor to generate compressed air, and the air-to-water volume ratio is 20:1;

[0099] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com