Sling type lifting tool

A sling and sling technology, applied in the field of hoisting slings, can solve problems such as limited use, inability to accurately hang workpieces, asymmetrical hanging positions, etc., achieve strong adaptability, not easy to fall off, and improve safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

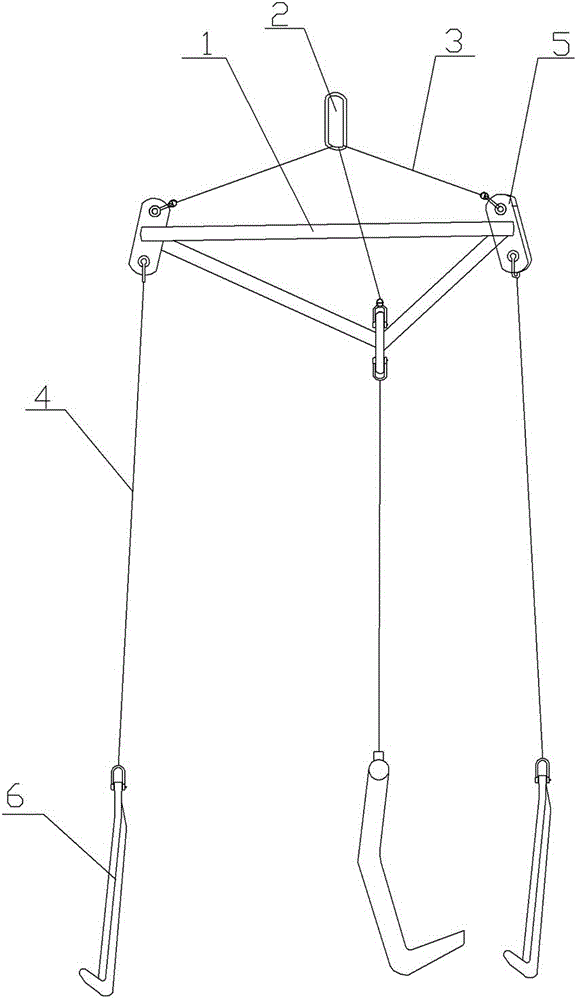

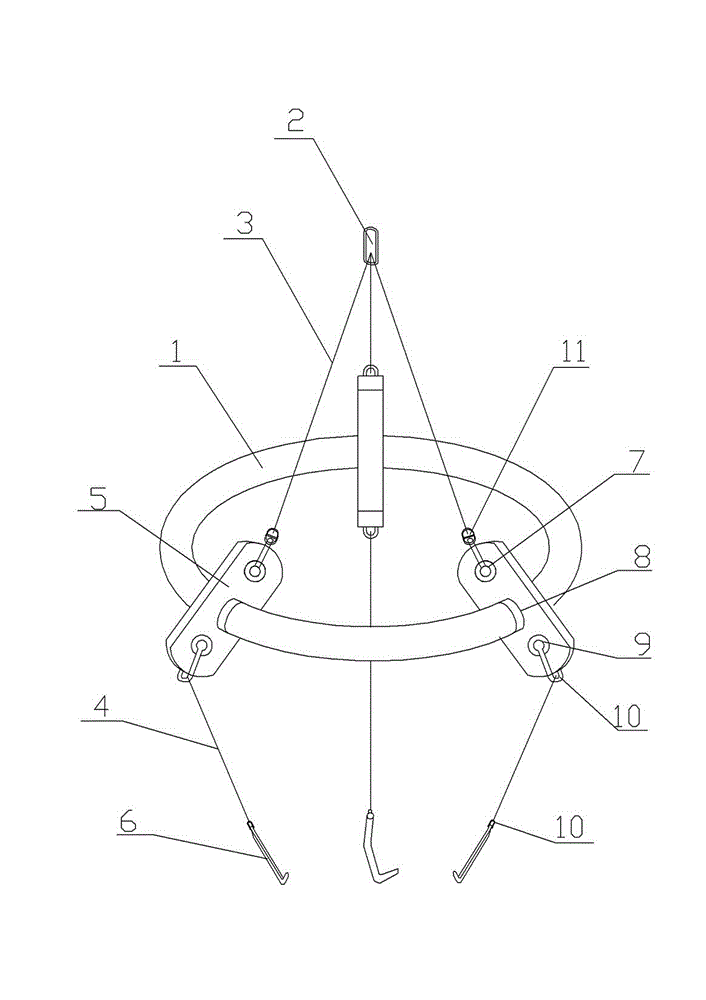

[0012] Such as figure 2 As shown, the present invention includes an annular connector 1, a suspension ring 2, an upper sling 3, a lower sling 4, a lifting ear 5, and a hook 6. The upper hanging hole 7, the lower hanging hole 9, and the installation hole 8. The installation hole 8 is located between the upper hanging hole 7 and the lower hanging hole 9. The outer wall of the connector 1 is slidingly fitted; the lower end of the upper sling 3 is connected with the upper hole 7 of the lifting ear 5 through a shackle 10; a butterfly buckle 11 is arranged between the lower end of the upper sling 3 and the shackle 10; the lower sling The upper end of the sling 4 is connected with the lower hanging hole 9 of the lifting ear 5 through a shackle 10; the lower end of the lower sling 4 is connected with the hook 6 through a shackle 10; the upper sling 3 and the lower sling 4 can be wire ropes , It can also be a lifting chain, which is selected according to the use occasion, and its len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com