Novel screw take-up device of belt type conveyor

A belt conveyor and tensioning device technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of reduced service life, inconvenient operation of personnel, bending and deformation of screw rods, etc., and achieve low noise, stable transmission and good use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

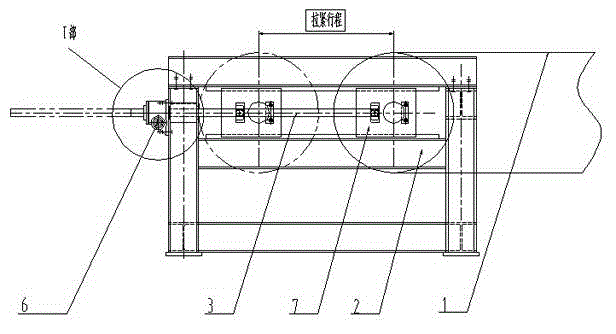

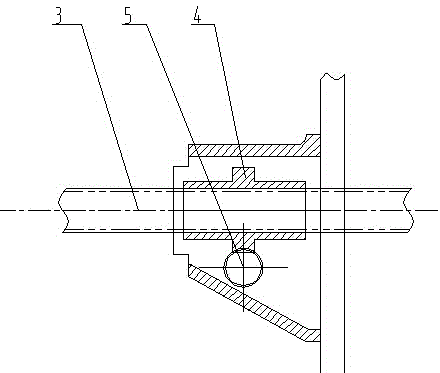

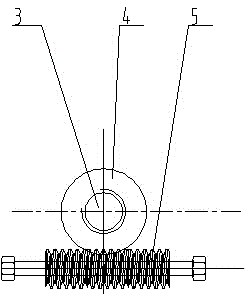

[0015] The present invention includes a drum 2 connected with a belt 1, and the drum 2 is provided with a screw 3 that drives the motion of the drum 2, and the screw 3 is sleeved in a worm wheel 4, and the worm 4 is provided with an internal thread that cooperates with the screw 3; the worm wheel 4 Driven by the worm 5, the worm 5 is externally equipped with a driving mechanism for driving the worm 5 to run.

[0016] The driving mechanism is a rotating nut 6 matched with the worm 5, and the rotating nut 6 is pulled by a wrench.

[0017] The drum 2 is connected with the screw mandrel 3 through a slider 7 .

[0018] The working principle of the tensioning device is as follows:

[0019] The present invention rotates the rotating nut 6 on the screw lifting mechanism with a wrench, thereby driving the worm 5 to rotate, and the worm 5 drives the worm wheel 4 to rotate, and the worm wheel 4 is provided with an internal thread matched with the screw rod 3, and drives the screw rod 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com