A three-motor hybrid drive truck and its power system parameter matching method

A technology for trucks and hybrid drives, applied in electric vehicles, electric braking systems, control drives, etc., can solve the problems of inability to fully recover braking energy, complex manufacturing processes, and high production costs, and achieve flexible braking energy recovery. , to ensure rationality, the effect of power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

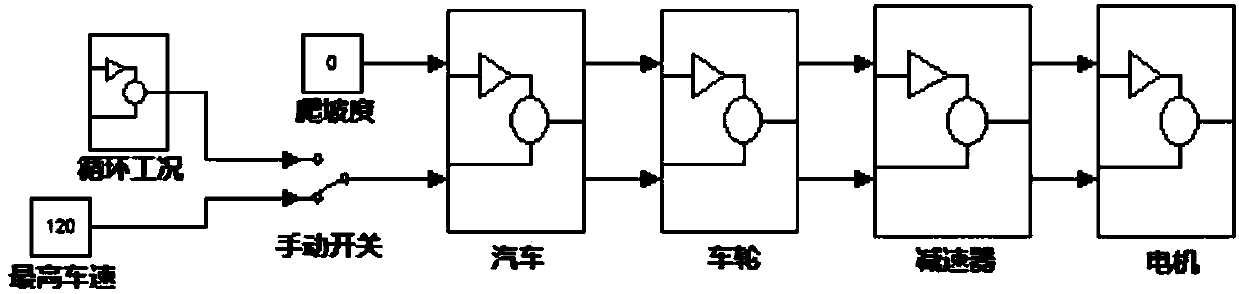

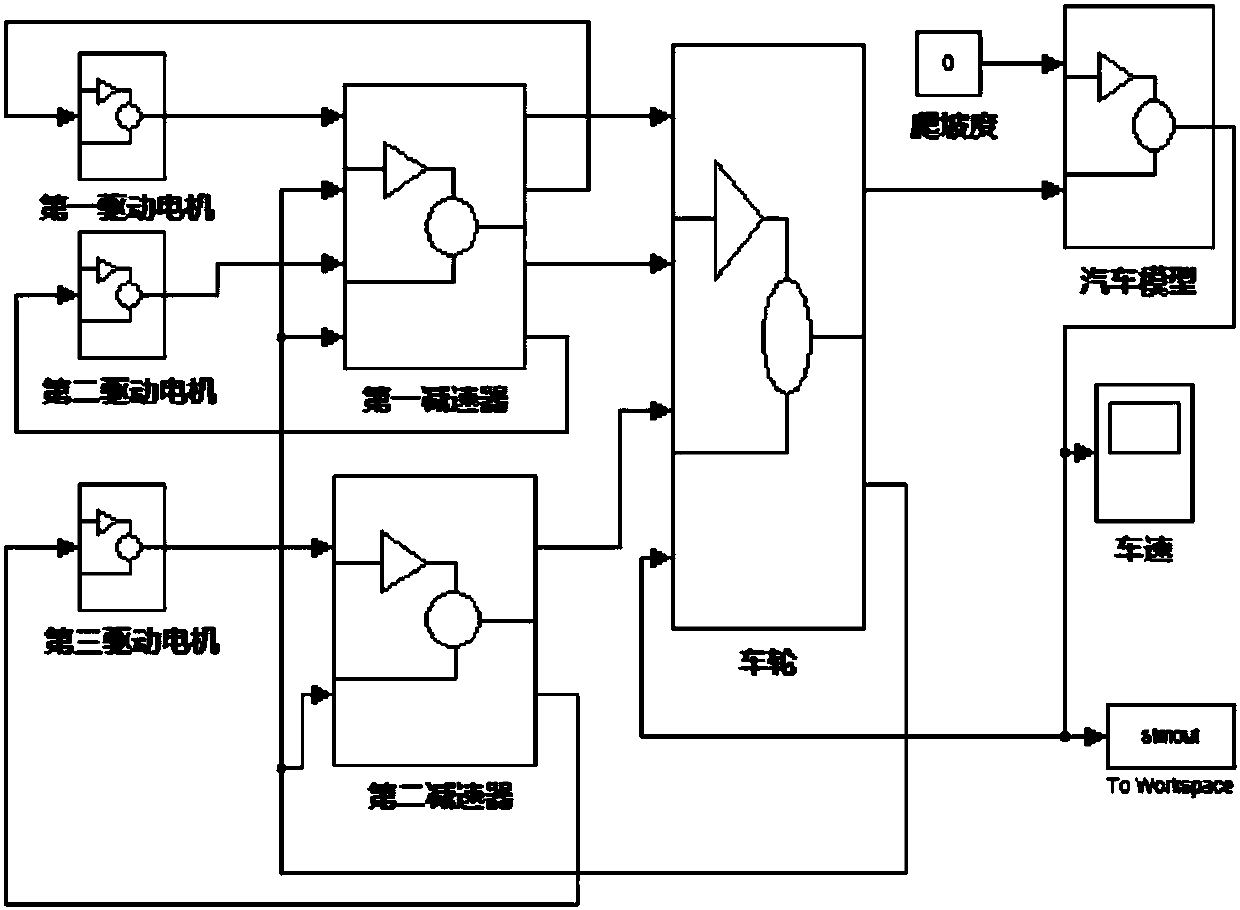

[0046] The applicant gave an embodiment of the present invention according to the specific vehicle model development process. The vehicle parameters of a certain type of light truck are: the curb weight (not including the battery) is 750kg, the battery quality is 480kg, the maximum load capacity is 1000kg, and the wheels roll The radius is 0.312m, the rolling resistance coefficient is 0.0076+0.00056u, u is the vehicle speed, and the windward area of the vehicle is 2.5m 3 , air resistance coefficient 0.6, rotating mass conversion coefficient 1.05; vehicle performance indicators are: maximum speed 120km / h, acceleration time from 0 to 80km / h≤15s, maximum gradeability ≥25%;

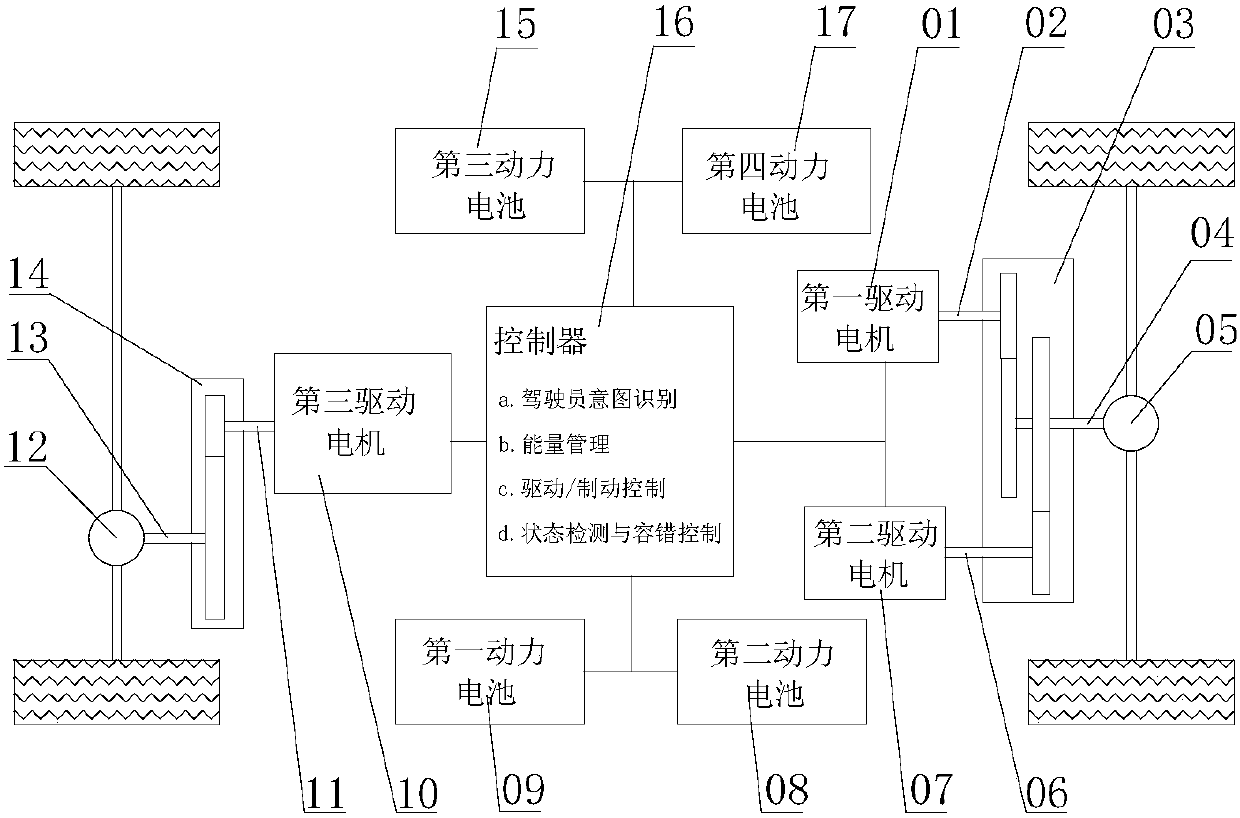

[0047] as attached figure 1 As shown: the three-motor hybrid drive truck includes a first drive motor 1, a first input shaft 2, a first reducer 3, a first output shaft 4, a front axle 5, a second input shaft 6, and a second drive Motor 7, first power battery 8, second power battery 9, third drive motor 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com