Dust-free screening and crushing integrated equipment

An all-in-one machine and equipment technology, applied in the fields of sieving, solid separation, smoke removal, etc., can solve the problems of crushing cost, high labor maintenance cost, serious dust pollution in crushed buildings, and harsh working environment, etc., to reduce the cleaning workload, The effect of reducing the content of civil works and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

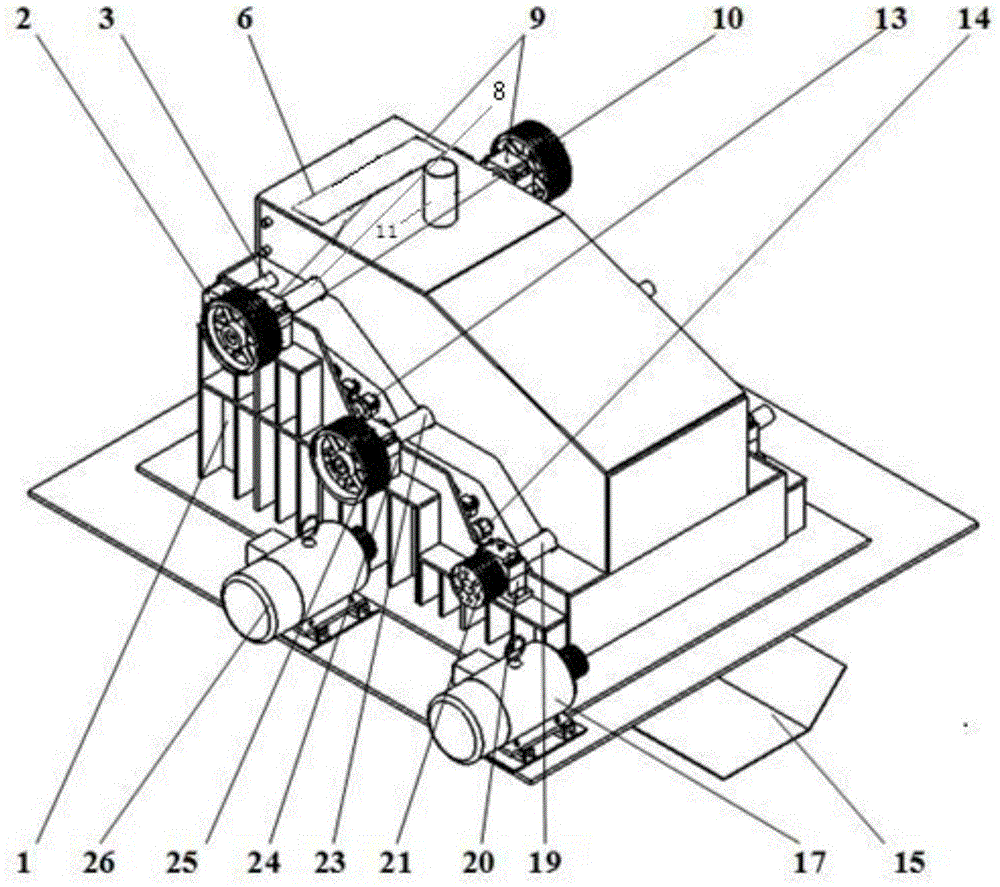

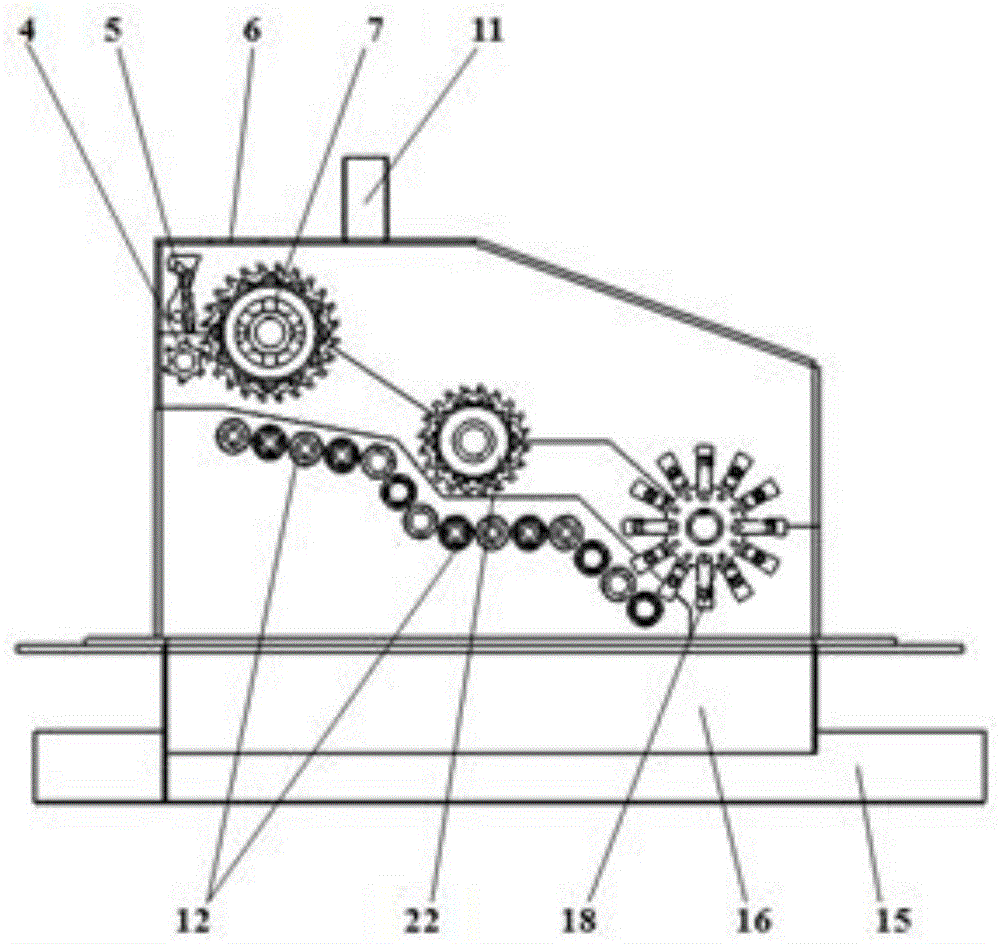

[0032] Such as figure 2 As shown, a dust-free screening and crushing integrated machine equipment according to an embodiment of the present invention includes a frame 1, a primary crushing device, a secondary crushing device, a tertiary crushing device, a screening device, and a dust removal device. All-in-one equipment is outdoors.

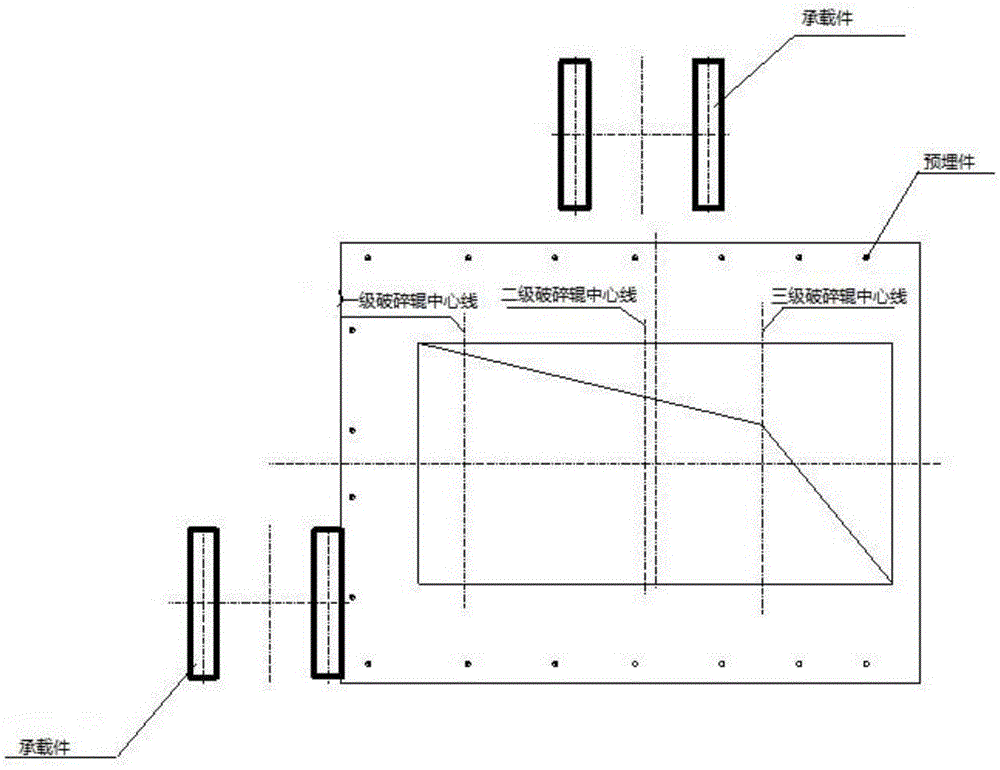

[0033] The frame 1 is stepped, and the three sides of the outer bottom of the frame 1 are fixed on the concrete pouring platform through embedded parts. The bottom of the outer frame is provided with a rubber plate 16, and a conveyor belt 15 is provided under the rubber plate 16 to convey The belt 15 is closely attached to the rubber plate to form a tight cavity, and the top of the frame is provided with a material inlet 6 and an air exhaust port 11 . Among them, such as image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com