Regulating-type central transmission mud scraper

A center-driven mud-scraping and adjustable technology, which is applied to chemical instruments and methods, separation methods, sedimentation and separation, etc., can solve the problems of easy damage to the mud scraper, poor mud scraping effect, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

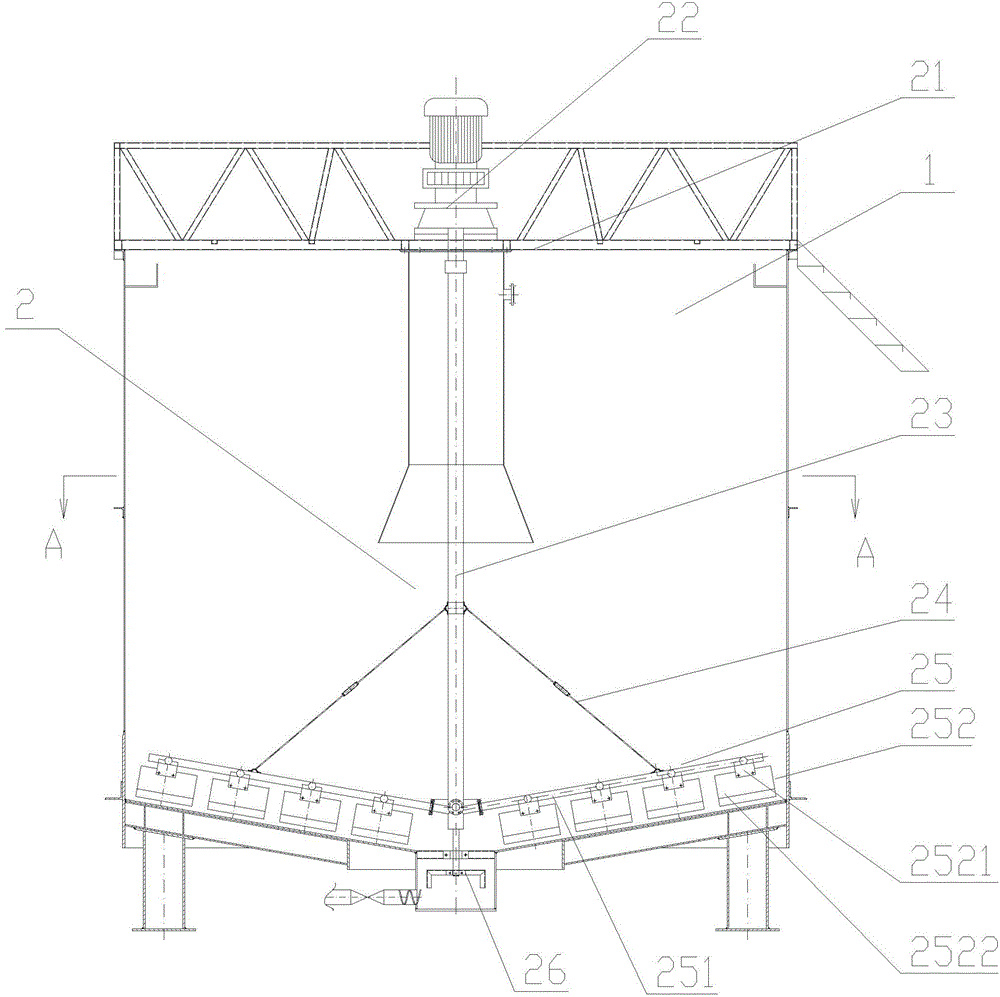

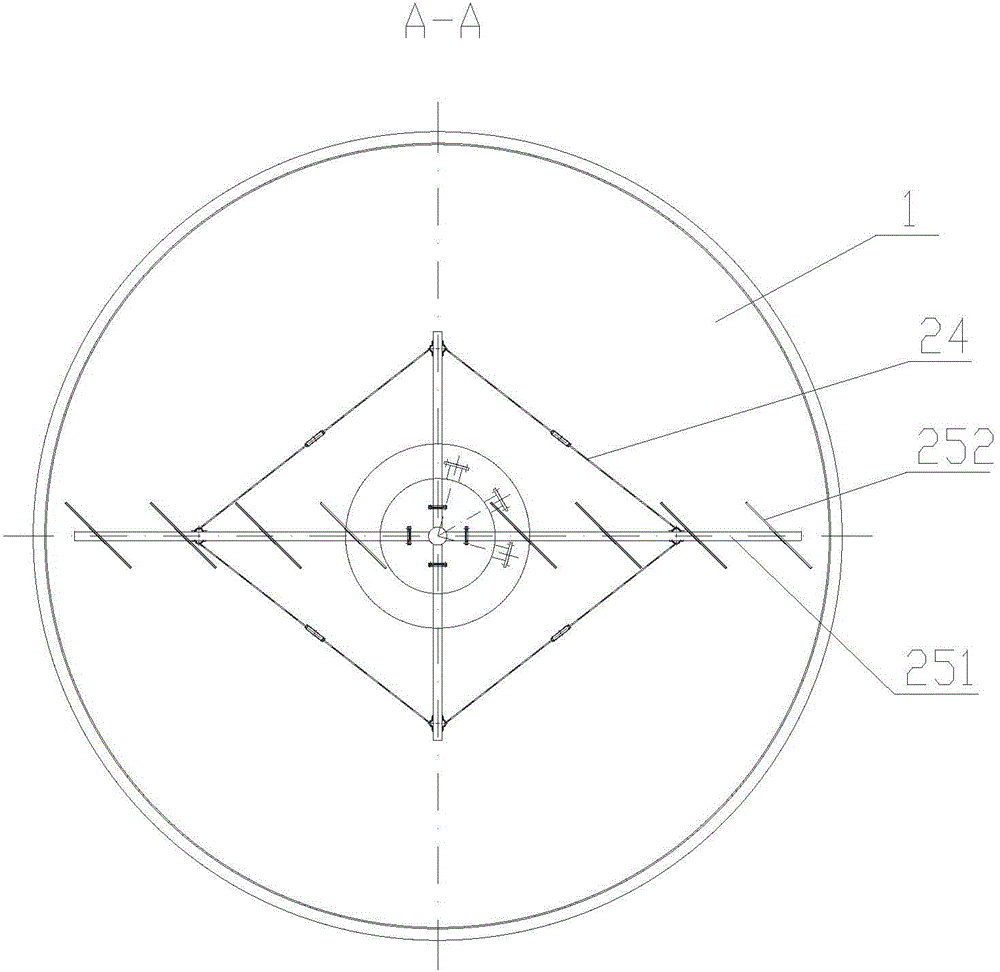

[0019] The present invention as Figure 1-4 As shown, the adjustable central drive mud scraper 2 is located in the center of the sedimentation tank 1. The mud scraper 2 includes a bracket 21, a motor 22, a transmission shaft 23, several pull rods 24 and at least two sets of evenly distributed mud scraper mechanisms. 25, the bracket 21 is set on the top of the sedimentation tank 1, the motor 22 is set on the bracket 1, the upper end of the transmission shaft 23 is connected to the output shaft of the motor 22, and the mud scraping mechanism 25 It is arranged symmetrically at the lower end of the transmission shaft 23 , and the pull rod 24 is arranged between the transmission shaft 23 and the mud scraping mechanism 25 to play a supporting role.

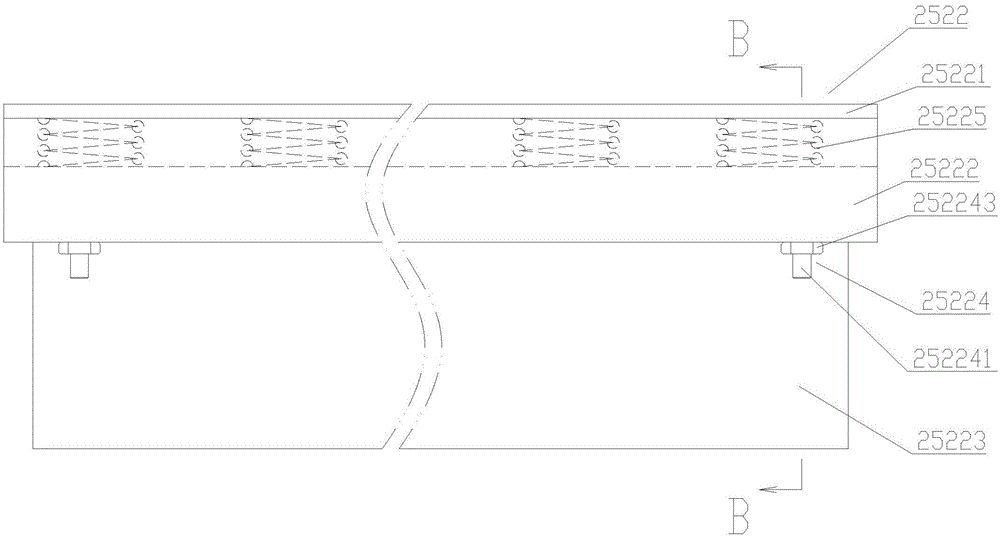

[0020] The scraper mechanism 25 includes a scraper arm 251 and several scraper units 252, the scraper units 252 are arranged parallel to each other and arranged obliquely to the vertical line on the horizontal plane of the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com