Meal substituting dessert and preparation method thereof

A dessert and meal replacement technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as tissue collapse and adverse sensory effects, and achieve the effect of uniform tissue state and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

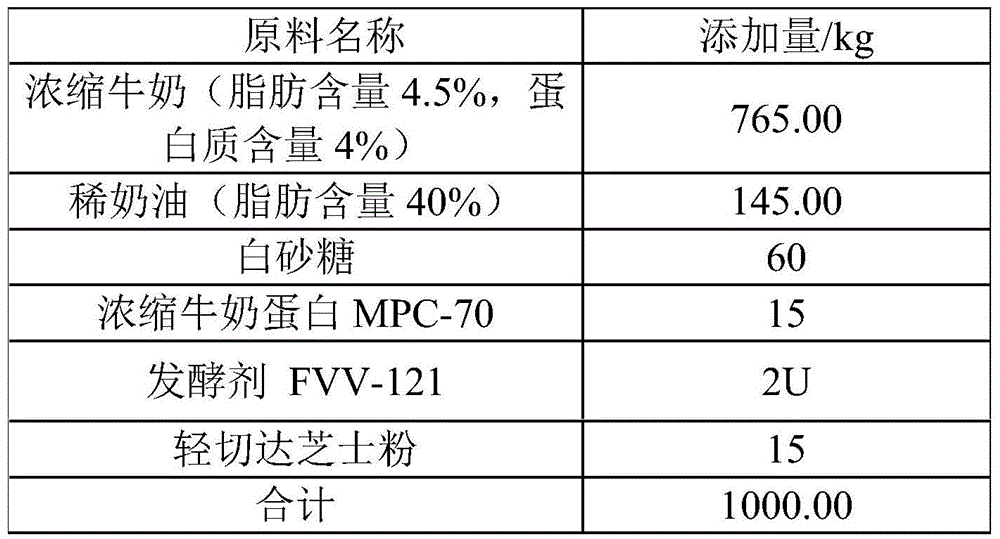

[0046] 1. Raw material formula

[0047] Table 1

[0048]

[0049] 2. Preparation method:

[0050] (1) Concentrated milk preparation: Concentrated milk is obtained by passing the qualified raw milk through a conventional flash evaporation process in the art;

[0051] First mix the cream and condensed milk evenly, and heat to 50°C; after mixing the condensed milk protein, cheese powder and white sugar, add it to the preheated cream and condensed milk mixture through a water-powder mixer, and stir for 30 minutes to obtain mixed liquid;

[0052] (2) homogenizing the mixed material liquid of step (1), sterilizing, and cooling to obtain a homogeneous material liquid;

[0053] Among them, the homogenization pressure is 18MPa, the homogenization temperature is 65°C; the sterilization temperature is 95°C, and the sterilization time is 10min; the temperature after cooling is 38°C;

[0054] (3) Inoculate the starter with the homogeneous material solution in step (2), mix and ferme...

Embodiment 2

[0057] 1. Raw material formula

[0058] Table 2

[0059]

[0060] 2. Preparation method:

[0061] (1) First mix the cream and condensed milk evenly, and heat to 65°C; after mixing the condensed milk protein, cheese powder and white sugar, add it to the preheated cream and condensed milk mixture through a water powder mixer, and stir 20min to get the mixed material liquid;

[0062] (2) homogenizing the mixed material liquid of step (1), sterilizing, and cooling to obtain a homogeneous material liquid;

[0063] Among them, the homogenization pressure is 12MPa, the homogenization temperature is 65°C; the sterilization temperature is 98°C, and the sterilization time is 5min; the temperature after cooling is 45°C;

[0064] (3) Inoculate the starter with the homogeneous material solution in step (2), mix and ferment, then stir and cool to obtain a meal replacement dessert; after filling it, refrigerate it at 4-10°C;

[0065] Wherein, the dosage of starter is 2U / 1000kg; the in...

Embodiment 3

[0067] 1. Raw material formula

[0068] table 3

[0069]

[0070] 2. Preparation method:

[0071] (1) Concentrated milk preparation: the qualified raw milk is subjected to a conventional double-effect concentration process in the art to obtain concentrated milk;

[0072] Mix the cream and condensed milk evenly, and heat to 65°C; after mixing the condensed milk protein, cheese powder and white sugar, add it to the preheated cream and condensed milk mixture through a water-powder mixer, and stir for 20 minutes to obtain mixed liquid;

[0073] (2) homogenizing the mixed material liquid of step (1), sterilizing, and cooling to obtain a homogeneous material liquid;

[0074] Among them, the homogenization pressure is 15MPa, the homogenization temperature is 65°C; the sterilization temperature is 95°C, and the sterilization time is 5min; the temperature after cooling is 43°C;

[0075] (3) Inoculate the starter with the homogeneous material solution in step (2), mix and ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com