Air-gas mixer units for premix burner installations

A gas mixer, premixed combustion technology, applied in combustion equipment, burners, gas fuel burners, etc., can solve the problems of cost and time, and achieve the effect of improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

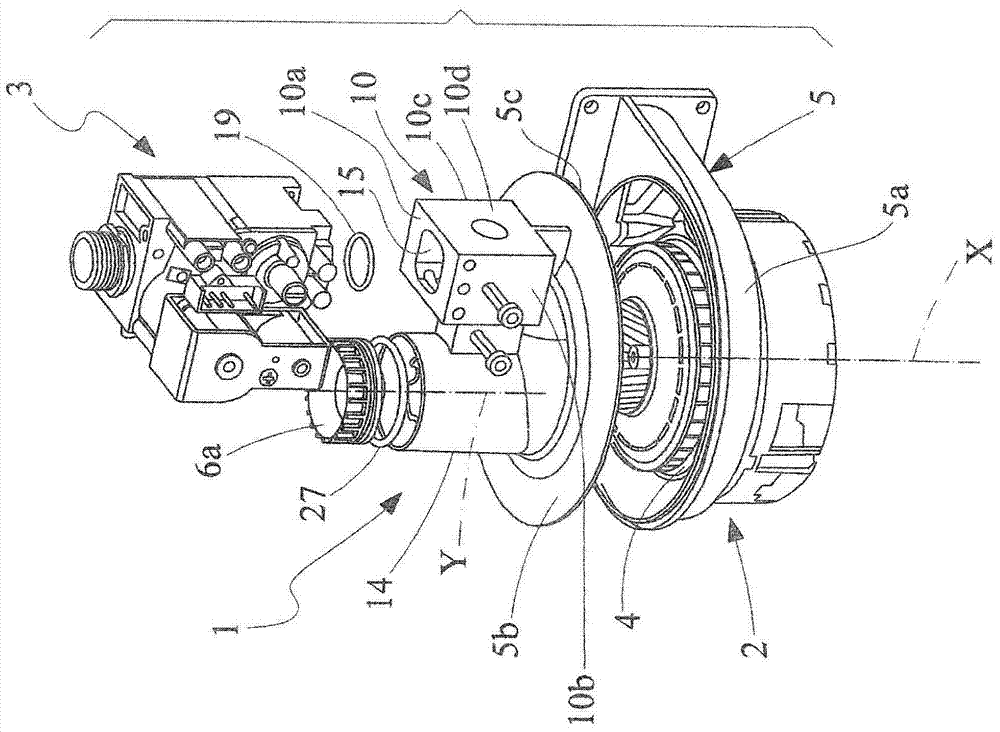

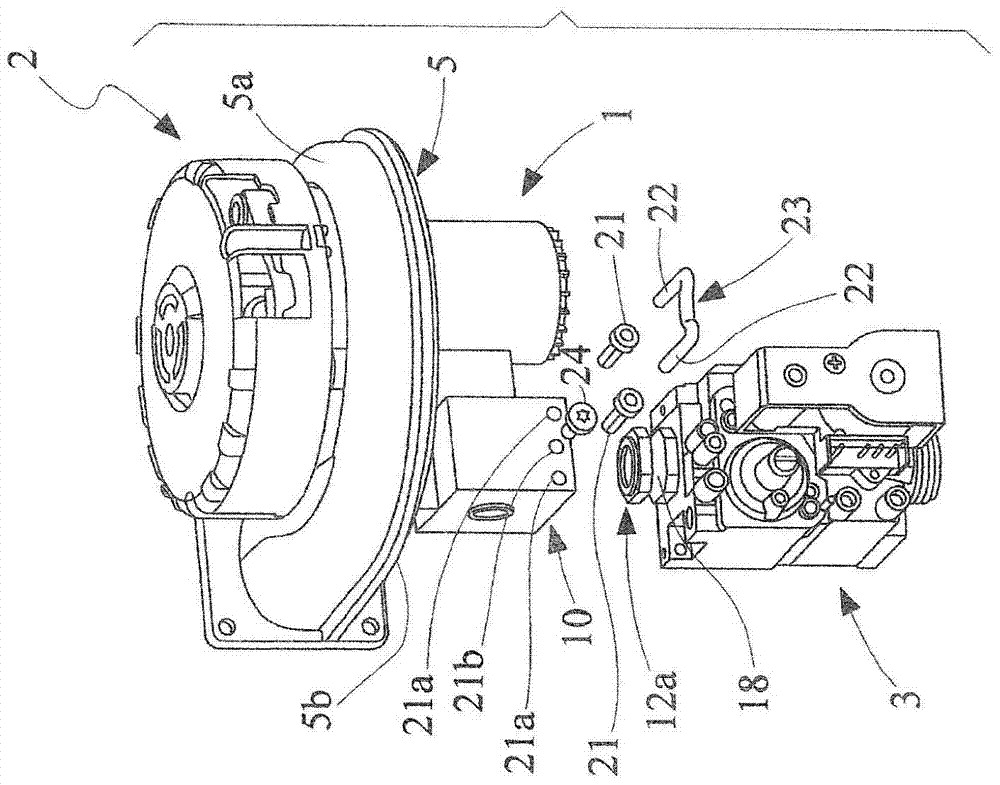

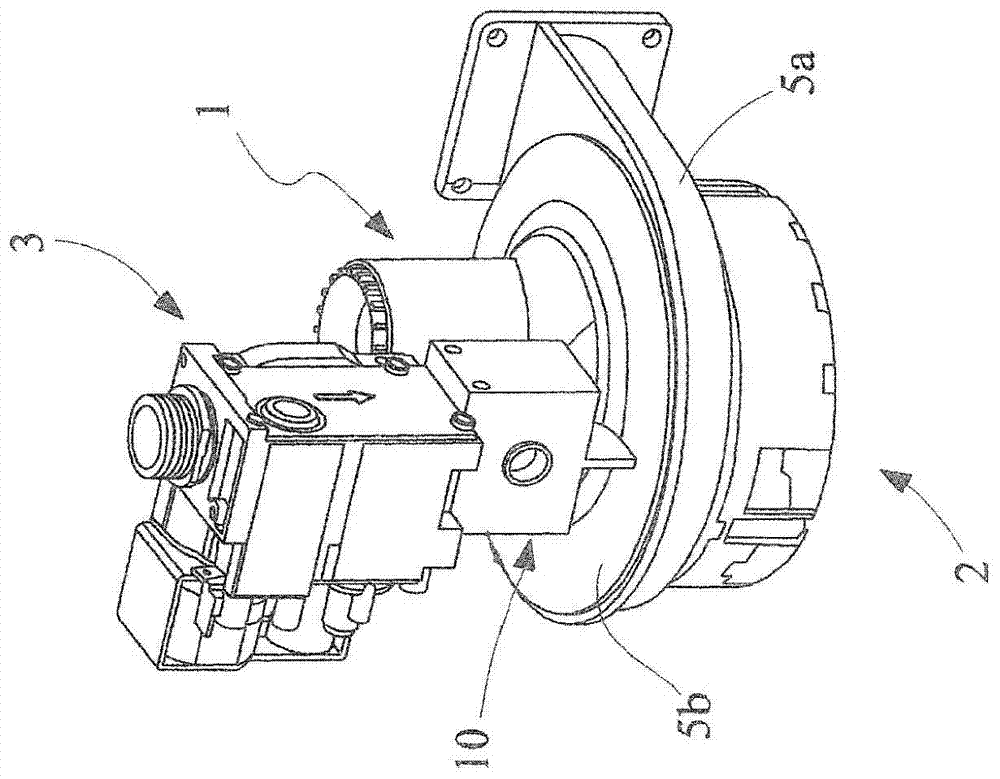

[0027] First refer to figure 1 , reference numeral 1 denotes an air-gas mixer made according to the invention, which is especially designed for burner installations using gas fuel for premixing.

[0028] The device 1 is designed to receive the air flow and the gas flow introduced into the device, and mix the air flow and the gas flow to form an air-gas fuel mixture, ready to be sent to the inlet section 2a of the centrifugal fan 2, which is also designed The air-gas fuel mixture is supplied in delivery mode to the head of a gas burner, not shown in the figure. The invention is particularly, but not exclusively, applicable to the premixing of air and gas for condensing boiler burners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com