Method for obtaining three-dimensional stress field of rock mass model including complex structural plane

A technology of complex structure and three-dimensional model, which is applied in the engineering field to achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0027] A method for obtaining a three-dimensional stress field of a rock mass model containing complex structural planes in the present invention comprises the following steps:

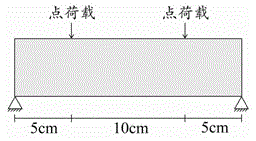

[0028] (1) Place the four-point bending test sample printed by the 3D printer in a temperature control box, apply a 4-point bending load, and irradiate polarized light, and continuously increase the temperature in the temperature control box from room temperature to the softening temperature of the rapid prototyping material. Determine the stress "freezing" streak value of rapid prototyping materials, and determine the best "freezing" temperature of rapid prototyping materials;

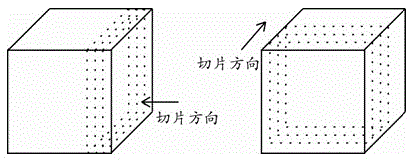

[0029] (2) Generate rock mass structural surface network system and rock mass CAD model: use mature three-dimensional structural surface network genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com