Optical driving flexible adjustable grating and preparation method thereof

An optical drive and grating technology, applied in the direction of diffraction grating, optics, optical components, etc., can solve the problems of inapplicable flammable and explosive gas spectrum monitoring, high requirements, and difficult to move, etc., to achieve real-time all-optical drive tuning, The effect of a wide range of grating period changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

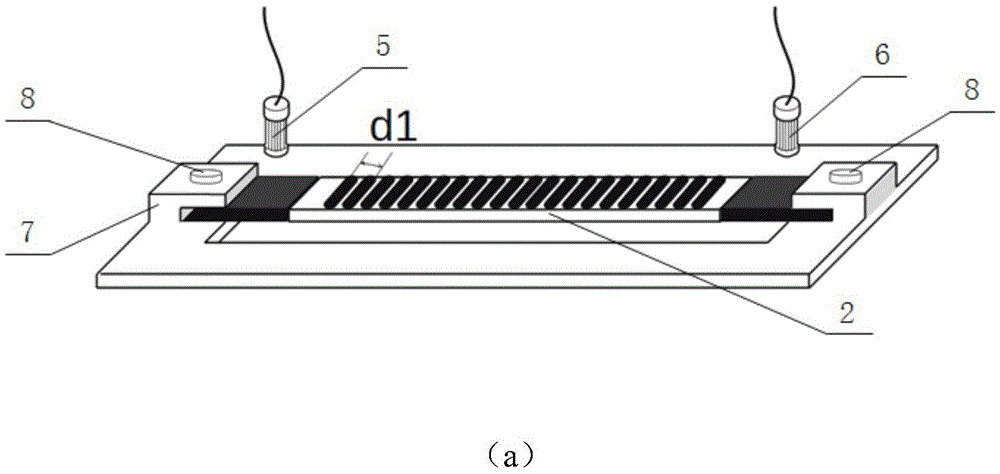

[0027] see figure 2 , a light-driven flexible tunable grating disclosed in the present invention consists of a polydimethylsiloxane film 3 and a graphene-polydimethylsiloxane film 4 arranged at both ends of the polydimethylsiloxane film 3 Composition; under the irradiation of a near-infrared laser, the graphene-polydimethylsiloxane film of the flexible tunable grating 2 can be stretched and deformed to change the grid spacing. The near-infrared laser irradiates the graphene-polydimethylsiloxane film to change the grid pitch of the flexible adjustable grating 2 .

[0028] At the bottom of the flexible adjustable grating 2, there is a grating template 1 for fixing the grid spacing, such as figure 1 shown.

[0029] Such as image 3 As shown in (a) and (b), the flexible tunable grating invol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com