Device for measuring thermal conductivity of fireproof material at high temperature

A technology of fireproof material and measuring device, applied in the field of building fireproof performance design, can solve the problems of complicated operation, expensive instrument, large size of test piece, etc., and achieve the effect of accurate thermal conductivity, low operating cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

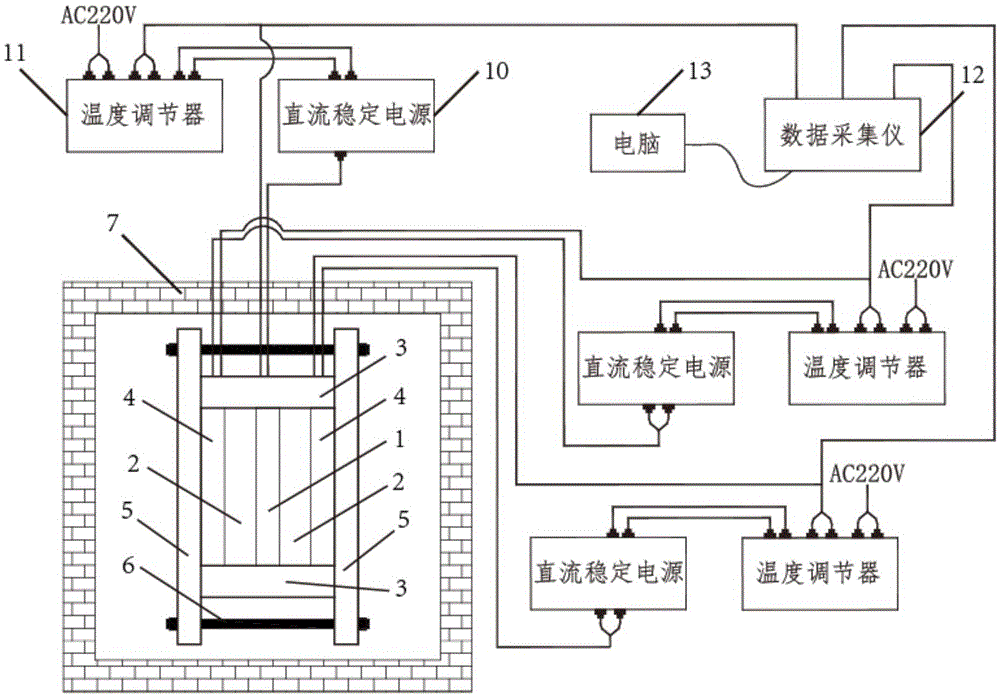

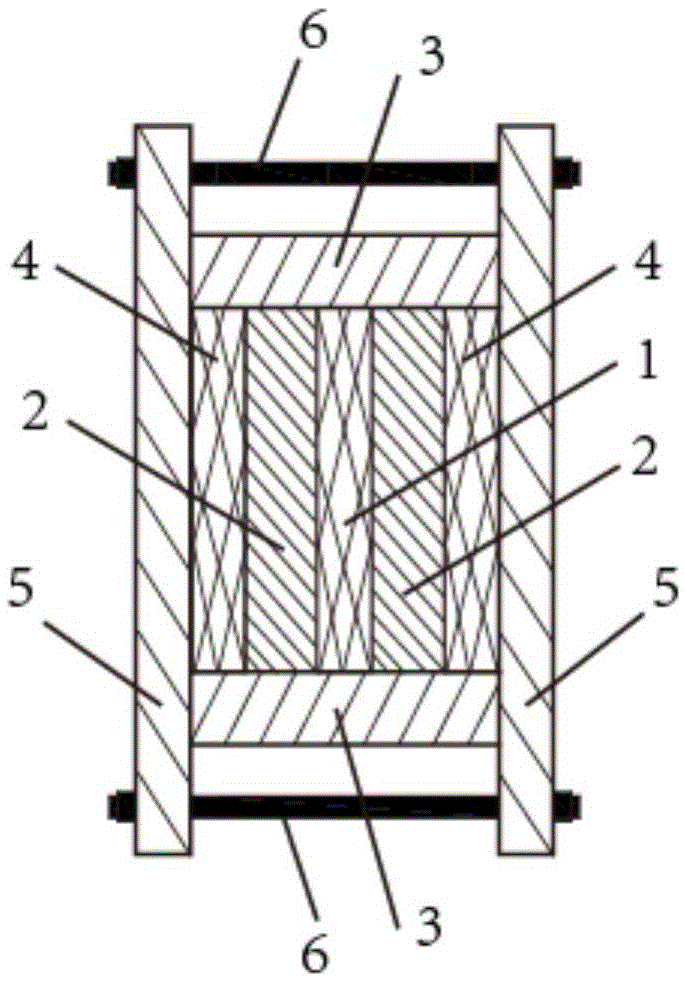

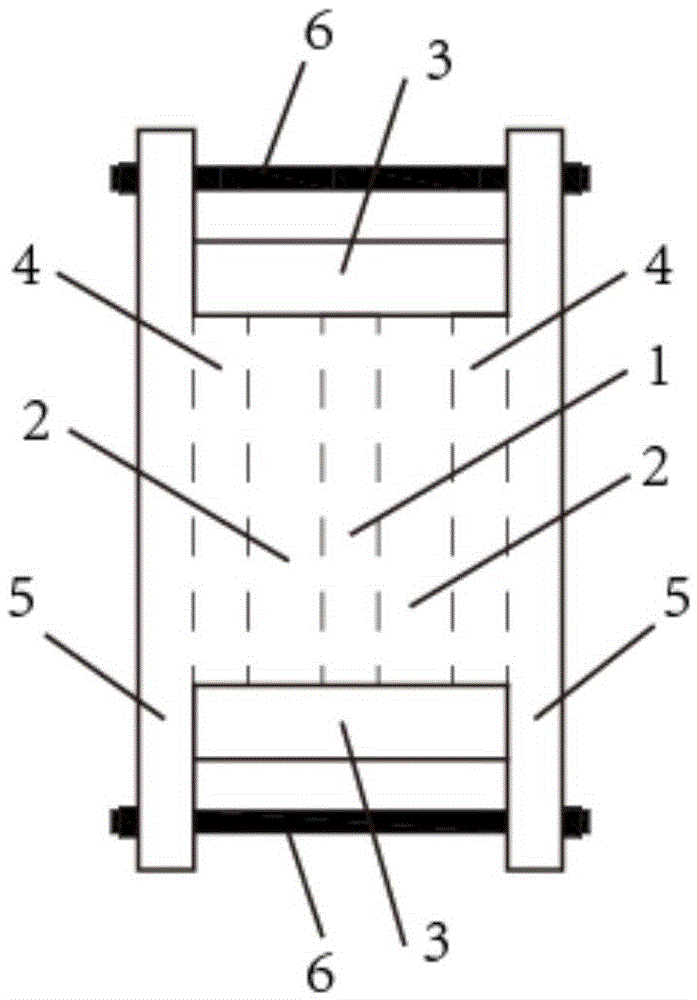

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0019] Such as Figure 1 to Figure 7 As shown, a device for measuring thermal conductivity of fireproof materials in high temperature, the device includes heating core board 1, heat insulation layer 3, low temperature side core board 4, heat conducting plate 5, electric furnace 7, single-head heating rod A8, single-head heating rod B8-1, thermocouple A9, thermocouple B9-1, DC stabilized power supply 10, temperature regulator 11, data acquisition instrument 12 and computer 13. When installing, first place the heat conduction plate 5 flat, place a low-temperature side core plate 4 in the middle of the heat conduction plate 5, place a plate-shaped fireproof material sample 2 above the low-temperature side core plate 4, and then place the heating core plate 1 is placed above the plate-shaped fireproof material sample 2, the plate-shaped fireproof material sample 2 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com