Anti-crease finishing agent for textiles and preparation method thereof

An anti-wrinkle finishing agent, a technology for textiles, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve problems such as easy wrinkling, and achieve the effects of uncomplicated process, improved elasticity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

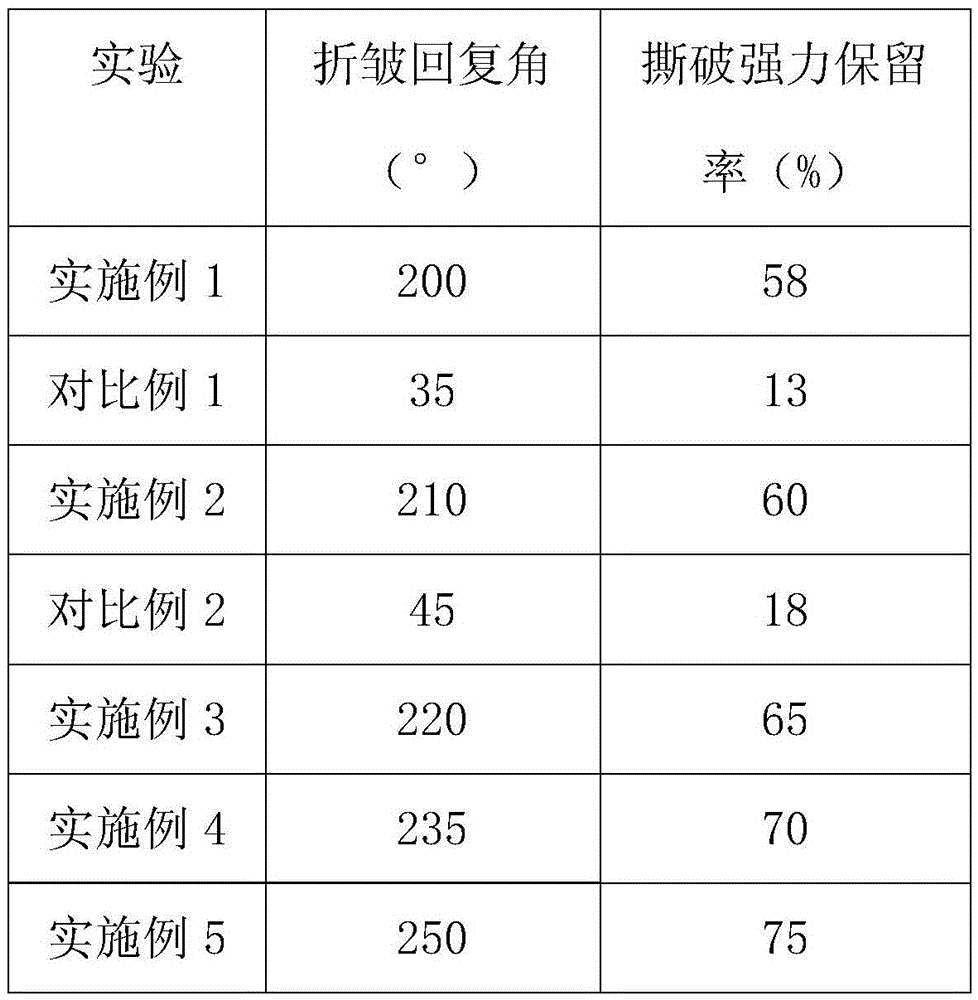

Examples

Embodiment 1

[0016] (1) Add 8 parts of salicylic hydroxamic acid, 3 parts of erucamide, 13 parts of glyoxal and 9 parts of maleic anhydride into the reaction kettle, raise the temperature to 40°C, and react for 20 minutes;

[0017] (2) Stir 15 parts of sodium methylnaphthalenesulfonate formaldehyde resin, 2 parts of trisodium citrate, 1 part of diethylene glycol and 35 parts of deionized water to a uniform state;

[0018] (3) Mix the reaction solution obtained in step (1) with the reaction solution obtained in step (2), then add 7 parts of ammonium persulfate and 3 parts of aluminum tartrate in sequence, feed nitrogen gas, and react at a temperature of 60°C at a rate of 300r / min After 1 hour, the anti-wrinkle finishing agent for textiles can be obtained after the reaction is completed.

Embodiment 2

[0024] (1) Add 15 parts of salicylic hydroxamic acid, 9 parts of erucamide, 18 parts of glyoxal and 15 parts of maleic anhydride into the reaction kettle, raise the temperature to 50°C, and react for 30 minutes;

[0025] (2) Stir 20 parts of sodium methylnaphthalenesulfonate formaldehyde resin, 6 parts of trisodium citrate, 5 parts of diethylene glycol and 45 parts of deionized water to a uniform state;

[0026] (3) Mix the reaction solution obtained in step (1) with the reaction solution obtained in step (2), then add 12 parts of ammonium persulfate and 8 parts of aluminum tartrate in sequence, feed nitrogen gas, and react at a temperature of 80°C at a rate of 500r / min After 1 hour, the anti-wrinkle finishing agent for textiles can be obtained after the reaction is completed.

Embodiment 3

[0032] (1) Add 10 parts of salicylic hydroxamic acid, 5 parts of erucamide, 14 parts of glyoxal and 11 parts of maleic anhydride into the reaction kettle, raise the temperature to 40°C, and react for 20 minutes;

[0033] (2) Stir 17 parts of sodium methylnaphthalenesulfonate formaldehyde resin, 3 parts of trisodium citrate, 2 parts of diethylene glycol and 38 parts of deionized water to a uniform state;

[0034] (3) Mix the reaction solution obtained in step (1) with the reaction solution obtained in step (2), then add 9 parts of ammonium persulfate and 5 parts of aluminum tartrate in sequence, feed nitrogen gas, and react at a temperature of 60°C at a rate of 300r / min After 1 hour, the anti-wrinkle finishing agent for textiles can be obtained after the reaction is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com