Detection device for detecting thickness of vacuum vapor plating membrane and vacuum vapor plating device

A detection device and a technology of evaporation film, which is applied in the field of vacuum evaporation device and detection device for detecting the thickness of vacuum evaporation film, can solve the problems of high production cost, improve the service life, prolong the time of vibration frequency drop, and reduce the evaporation process cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

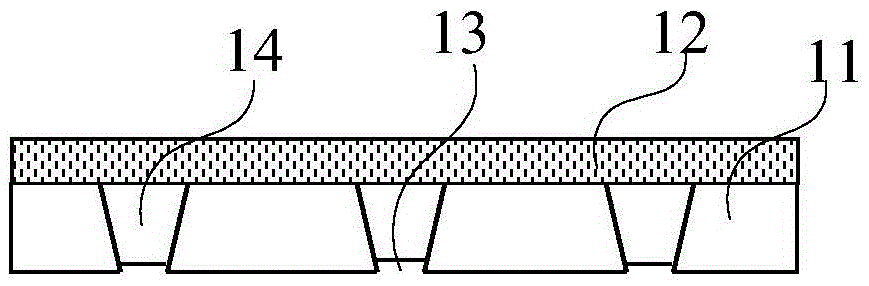

[0032] Embodiments of the present invention provide a detection device for detecting the thickness of a vacuum evaporation film and a vacuum evaporation device to solve the problem of high production cost caused by frequent replacement of crystal oscillators in the prior art.

[0033] The present invention will be described below in conjunction with the accompanying drawings. It should be noted that the drawings are only structural schematic diagrams, not true to scale. And it is only for explaining the present invention more clearly, but not limiting the present invention.

[0034] see Figure 1a and Figure 1b The detection device for detecting the thickness of the vacuum evaporated film provided by the embodiment of the present invention includes: a detection structure 11 and a crystal oscillator 12, and the detection structure 11 is provided with an opening 13 corresponding to the crystal oscillator, so that the evaporated molecules pass through the The opening is deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com