Hydrophilic modification method of methyl cellulose

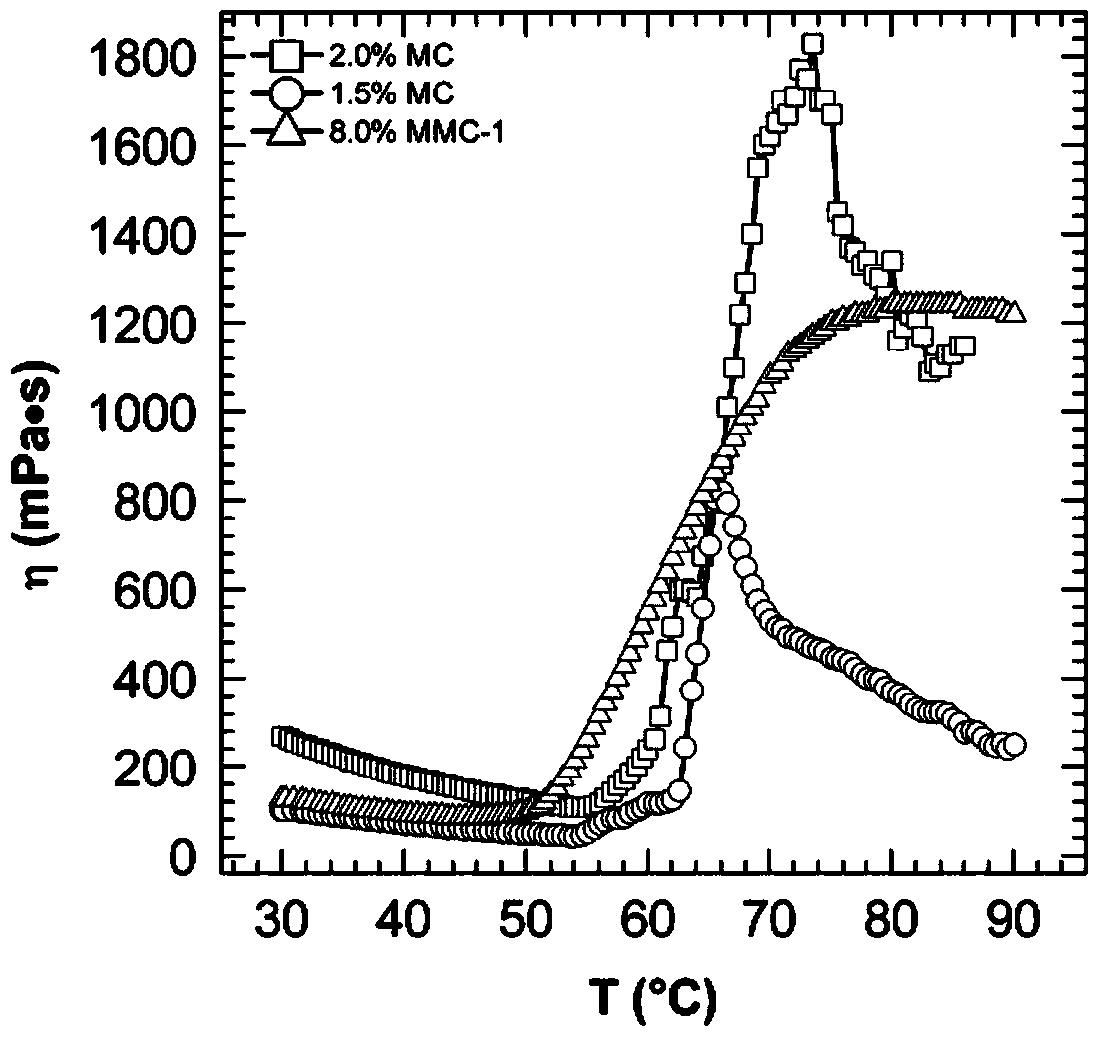

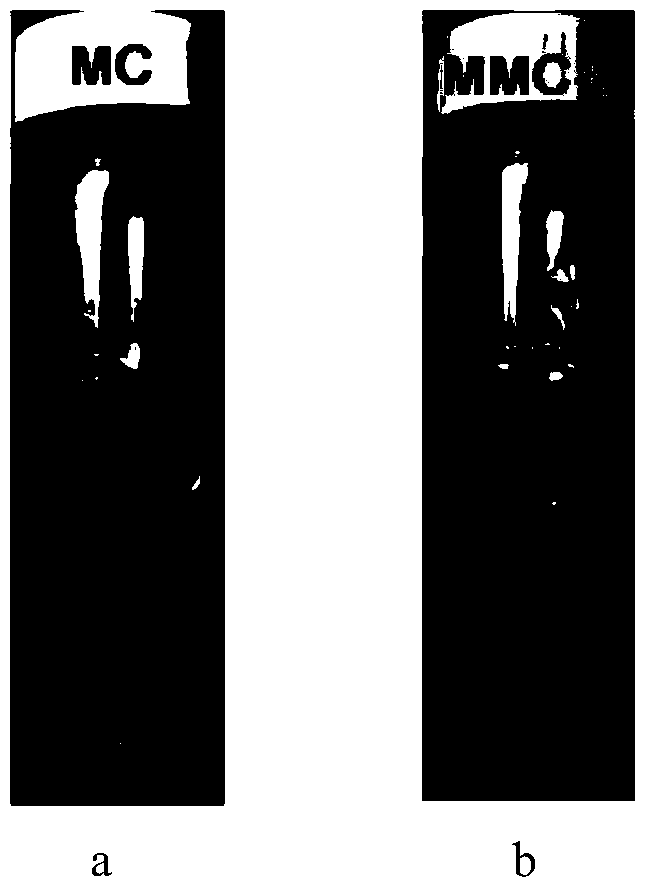

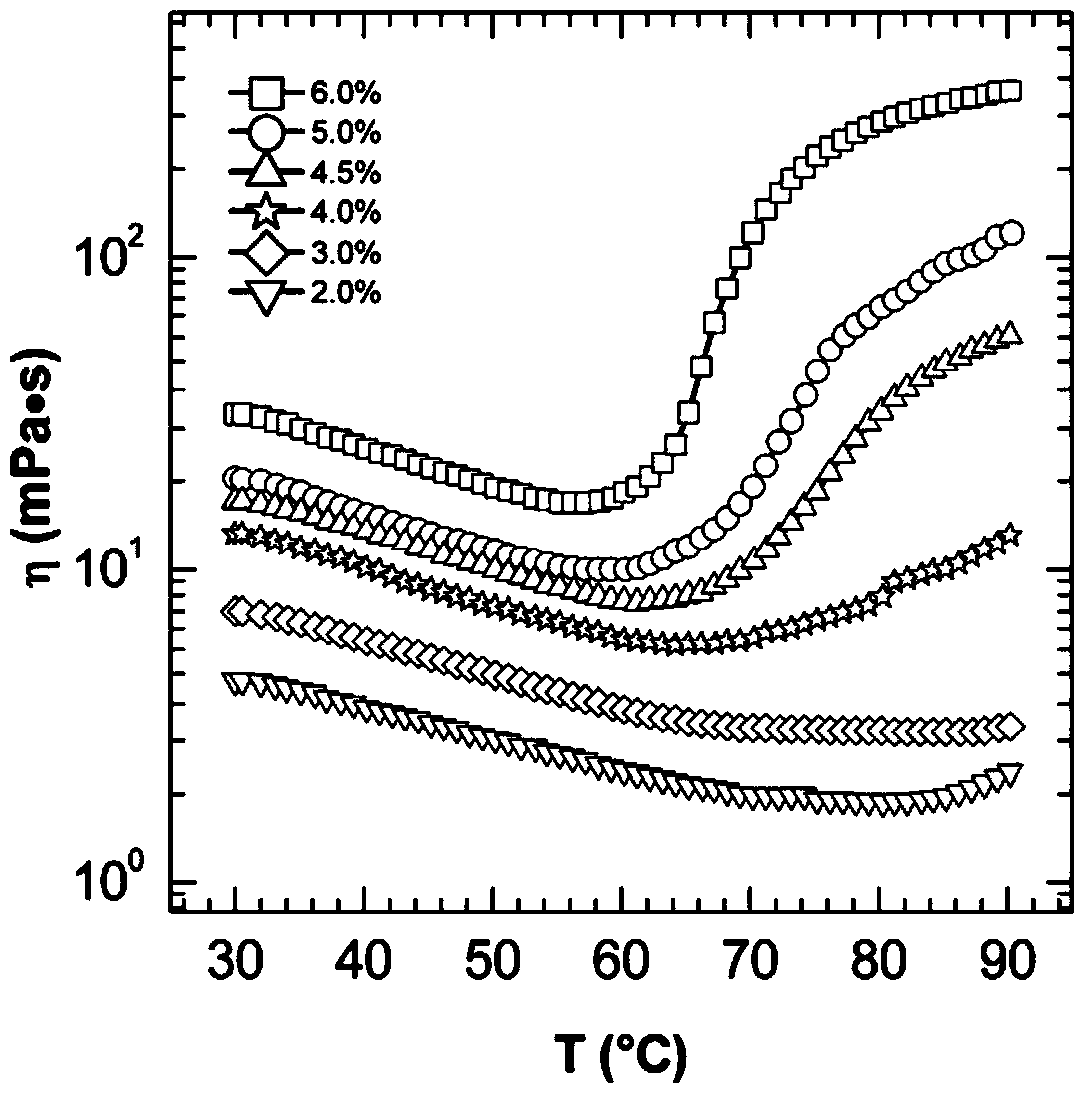

A technology of methyl cellulose and hydrophilic modification, applied in the field of hydrophilic modification of methyl cellulose, can solve problems such as viscosity reduction, limitation of methyl cellulose application, dehydration of polymer solutions, etc., and achieve easy operation, Elimination of macroscopic phase separation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Methylcellulose (MC) is dissolved in the NaOH solution that mass concentration is 6.0% and is mixed with the 100g methylcellulose solution that methylcellulose mass concentration is 2.0%, in the gained methylcellulose solution, add 8.67g of acrylamide monomer was stirred until dissolved to form a mixed solution, then stirred and reacted at 25°C for 24 hours, after the reaction was completed, hydrochloric acid was added to the obtained reaction solution to neutralize the reaction solution to neutrality, and then excess ethanol was added to obtain a precipitate. The filter cake was obtained by filtration, washed with deionized water for 3 times, and then vacuum-dried to obtain an intermediate product.

[0028] (2) The NaOH solution that is 0.8% mass concentration is made into the solution of intermediate product mass concentration 2.0% by the NaOH solution of gained intermediate product, adds 1g NaClO and mixes in gained solution, then is reacted at 25 ℃ under stirring...

Embodiment 2

[0030] (1) Methylcellulose (MC) is dissolved in the NaOH solution that mass concentration is 8.0% and is mixed with the 100g methylcellulose solution that methylcellulose mass concentration is 2.0%, in gained methylcellulose solution, add 8.67g of acrylamide monomer and stirred until dissolved to form a mixed solution, then stirred and reacted at 35°C for 18 hours, after the reaction was completed, added hydrochloric acid to the obtained reaction solution to neutralize the reaction solution to neutrality, and then added excess absolute ethanol to obtain a precipitate , and filtered to obtain a filter cake, which was washed with deionized water for 3 times and then vacuum-dried to obtain an intermediate product.

[0031] (2) The NaOH solution with a mass concentration of 0.8% is made into a solution with a mass concentration of the intermediate product of 2.0% by the obtained intermediate product, and 1g NaClO is added to the obtained solution and mixed uniformly, then reacted a...

Embodiment 3

[0033](1) Methyl cellulose (MC) is dissolved in the KOH solution that mass concentration is 8.0% and is mixed with the 100g methyl cellulose solution that methyl cellulose mass concentration is 2.0%, in the gained methyl cellulose solution, add Stir 5g of acrylamide monomer until dissolved to form a mixed solution, then stir and react at 20°C for 48 hours, add sulfuric acid to the resulting reaction solution to neutralize the reaction solution after the reaction is complete, then add excess absolute ethanol to obtain a precipitate, filter Obtain a filter cake, wash the filter cake with deionized water 3 times, and then vacuum-dry to obtain an intermediate product.

[0034] (2) the NaOH solution that is 0.8% is made into the solution of intermediate product mass concentration 1.0% by the NaOH solution of gained intermediate product with mass concentration, in gained solution, add 20g NaClO and mix homogeneously, then react at 25 ℃ under stirring, dark conditions , add excess Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com