Method for extracting lithium salt from high magnesium-lithium ratio saline water in electrochemical way

A technology of high magnesium-to-lithium ratio and lithium extraction, applied in the direction of alkali metal chloride, etc., can solve the problems of high water consumption, pollution, equipment corrosion environment, etc., and achieve the effects of overcoming high water consumption, low cost, and non-toxic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 200mg spinel LiMn respectively 2 o 4 , 25mg acetylene black conductive agent and 25mg polyvinylidene fluoride PVDF binder, weigh 808.3mg N-methylpyrrolidone NMP, dissolve polyvinylidene fluoride PVDF binder in N-methylpyrrolidone NMP, and then add the weighed Amount of spinel LiMn 2 o 4 and acetylene black conductive agent, fully stirred to form a slurry, and the slurry was evenly coated on the titanium mesh collector fluid, and the loading capacity of solid matter was 10mg / cm 2 , and then vacuum dried at 80 °C for 8 hours to obtain LiMn 2 o 4 electrode;

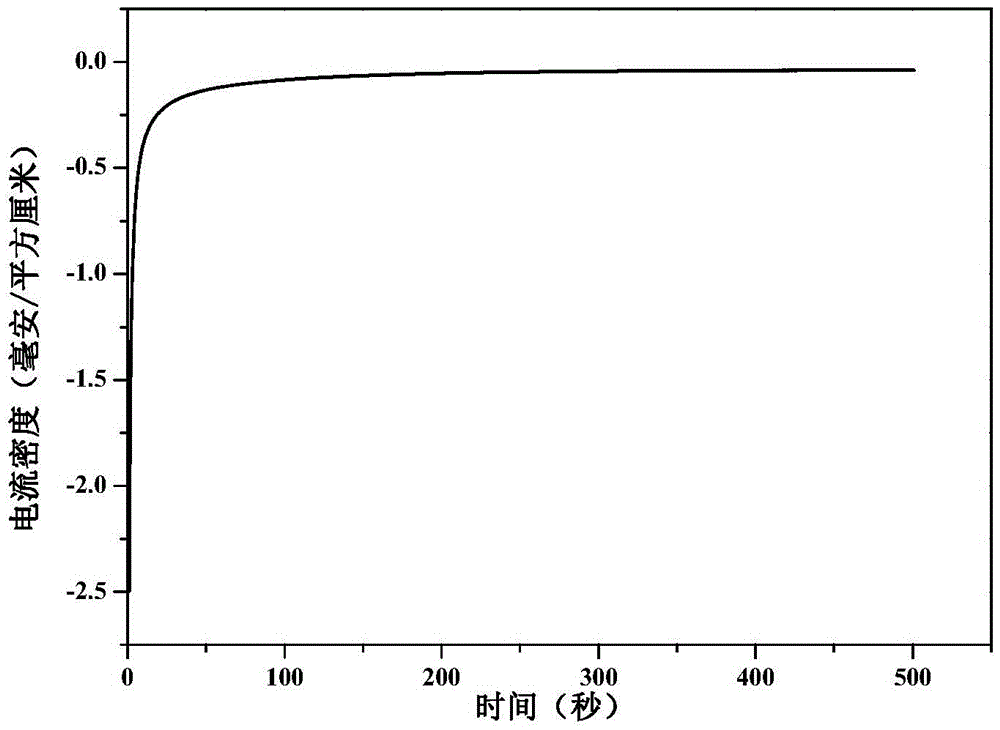

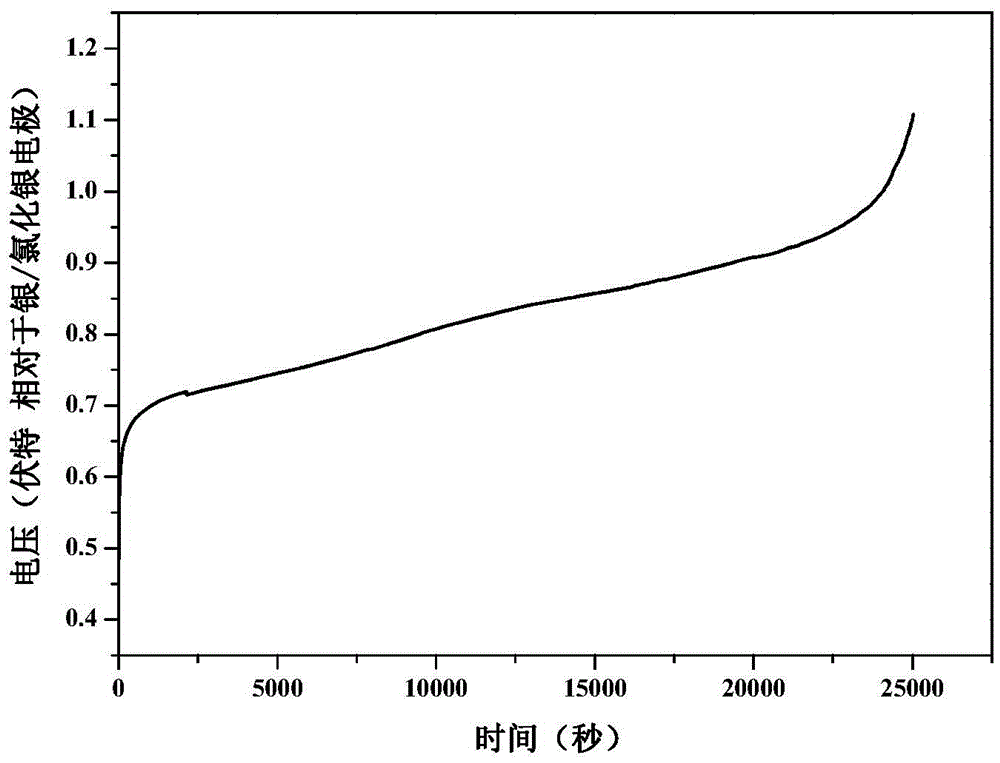

[0028] (2) The titanium mesh was used as the working electrode and the counter electrode, the Ag / AgCl electrode was used as the reference electrode, and the LiCl solution with a concentration of 0.01mol / L was used as the electrolyte solution to form an electrochemical reaction system; 1V (vs .Ag / AgCl) voltage charging for 10min, chlorine ions are adsorbed on the surface of the titanium mesh working ele...

Embodiment 2

[0035] (1) Weigh 200mg spinel LiMn respectively 2 o 4 , 80mg acetylene black conductive agent and 120mg polyvinylidene fluoride PVDF binder, weigh 5.88g N-methylpyrrolidone NMP, dissolve polyvinylidene fluoride PVDF binder in NMP in N-methylpyrrolidone, and then add the weighed Amount of spinel LiMn 2 o 4 and acetylene black conductive agent, fully stirred to form a slurry, and the slurry was evenly coated on the titanium net collector fluid, and the loading capacity of solid matter was 5mg / cm 2 , and then dried under vacuum at 50 °C for 5 hours to obtain LiMn 2 o 4 electrode;

[0036] (2) The titanium mesh is used as the working electrode and the counter electrode, the Ag / AgCl electrode is used as the reference electrode, and the LiCl solution with a concentration of 0.005mol / L is used as the electrolyte solution to form an electrochemical reaction system; apply 0.9V ( vs.Ag / AgCl) voltage charging for 5min, chlorine ions are adsorbed on the surface of the titanium mesh ...

Embodiment 3

[0042] (1) Weigh 200mg spinel LiMn respectively 2 o 4 , 11.8mg acetylene black conductive agent and 23.6mg polyvinylidene fluoride PVDF binder, weigh 448.4mg N-methylpyrrolidone NMP, dissolve polyvinylidene fluoride PVDF binder in N-methylpyrrolidone NMP, and then add Weighed spinel LiMn 2 o 4 and acetylene black conductive agent, fully stirred to form a slurry, and the slurry was evenly coated on the titanium mesh collector fluid, and the loading capacity of solid matter was 15mg / cm 2 , and then vacuum dried at 100 °C for 10 h to obtain LiMn 2 o 4 electrode;

[0043] (2) The titanium mesh is used as the working electrode and the counter electrode, the Ag / AgCl electrode is used as the reference electrode, and the LiCl solution with a concentration of 0.05mol / L is used as the electrolyte solution to form an electrochemical reaction system; apply 0.95V to the titanium mesh working electrode ( vs.Ag / AgCl) voltage charging for 20min, chlorine ions are adsorbed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com