Cardboard turning machine

A turning machine and cardboard technology, which is applied in the direction of turning objects, pile separation, thin material processing, etc., can solve the problems of corrugated cardboard such as long operation period, reduced production efficiency, and high labor intensity, so as to facilitate automatic production, improve production efficiency, good flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] For ease of illustration (but not limitation), the direction of travel of the cardboard is defined as front-to-back and derived left and right.

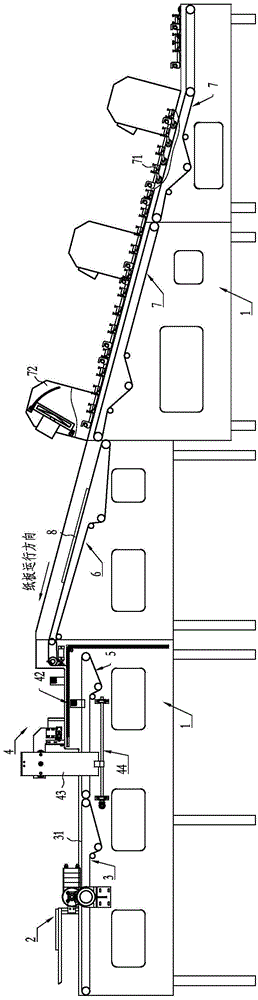

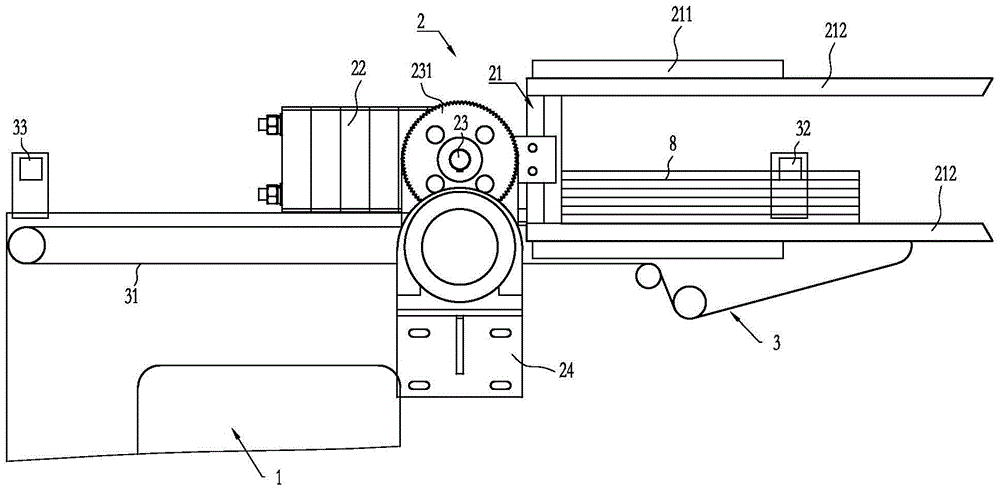

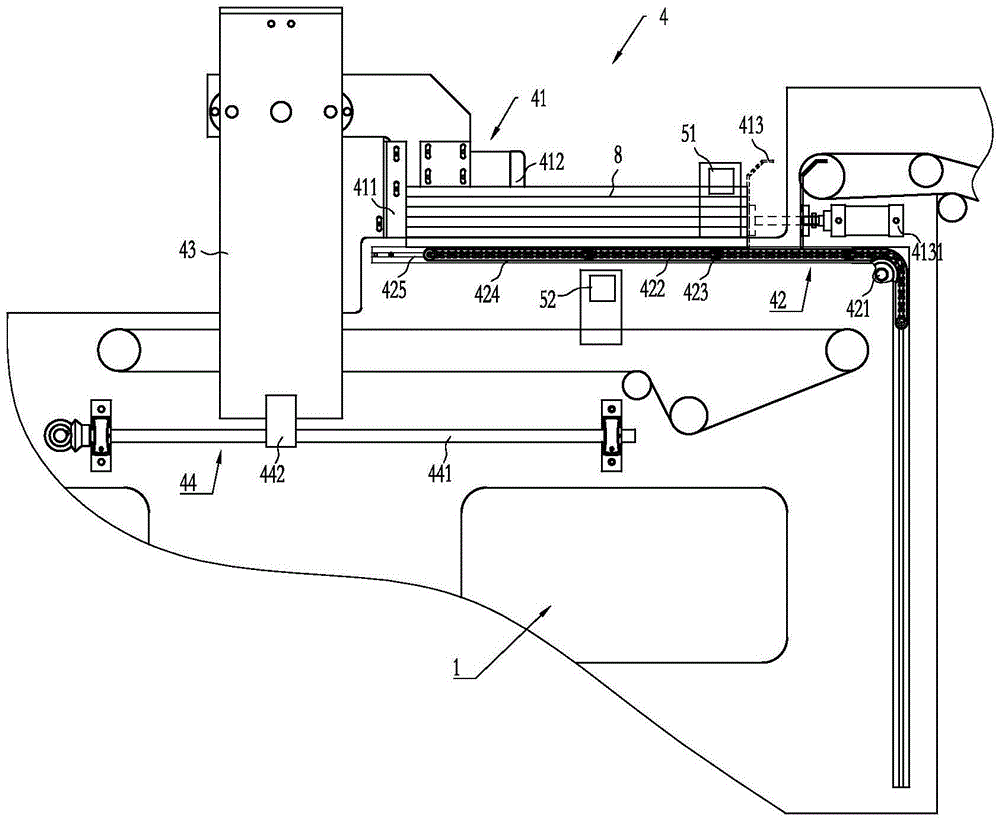

[0027] Such as figure 1 As shown, the frame 1 of the cardboard turning machine is sequentially provided with a first conveyor belt device 3 , a second conveyor belt device 5 , a fourth conveyor belt device 6 and a third conveyor belt device 7 from front to back. Among them, in order to make the upstream and downstream equipment adapt to each other in height, the third conveyor belt device 7 and the fourth conveyor belt device 6 are arranged obliquely; The delivery unit arranges the cardboards into piles for preparation, and the conveying speed of the fourth conveyor belt device 6 is lower than the conveying speed of the third conveyor belt device 7; The pressure roller 71 can prevent the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com