Method for optimizing warping deformation and technological parameters of flat injection-molded part

A technology for process parameter optimization and process parameter application in the field of flat injection molding and injection molding processing, which can solve problems such as low efficiency, improve analysis efficiency and reduce labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

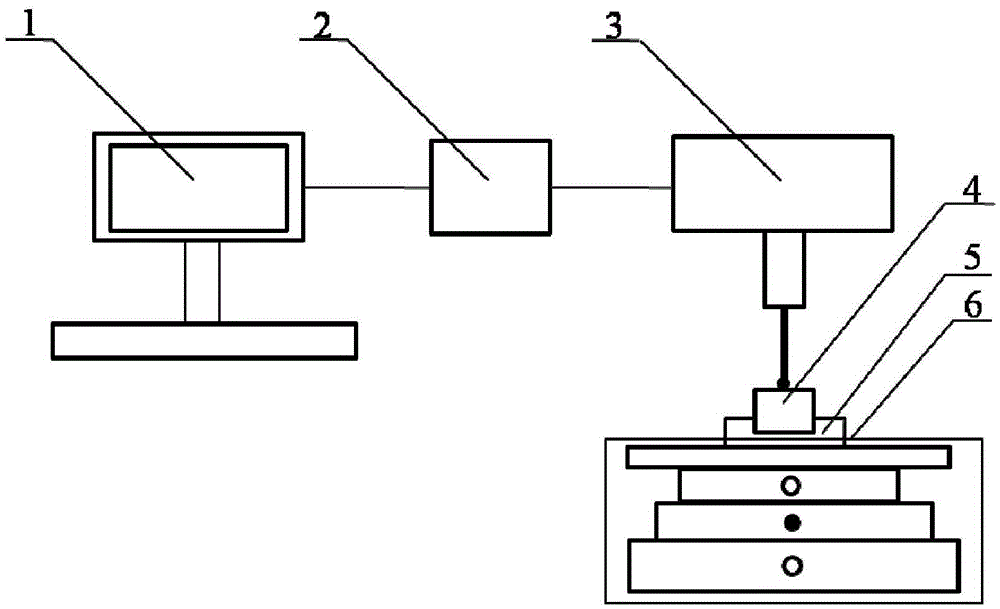

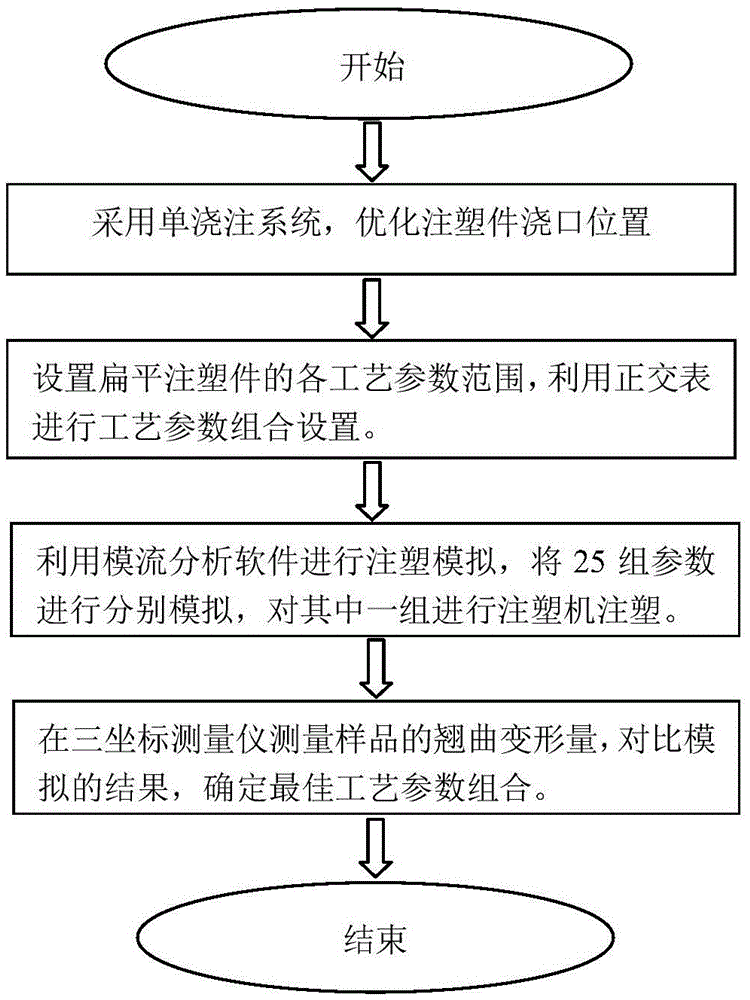

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and tables.

[0021] The sample used in this embodiment is a mobile phone card slot of a certain type, the injection molding material is PBT, its geometric size is 28.57mmx11.47mmx0.56mm, and a single gate casting system is adopted.

[0022] Step 1: Use the MPI of Moldflow software to optimize the gate position of the flat injection molded part and determine the best gate position.

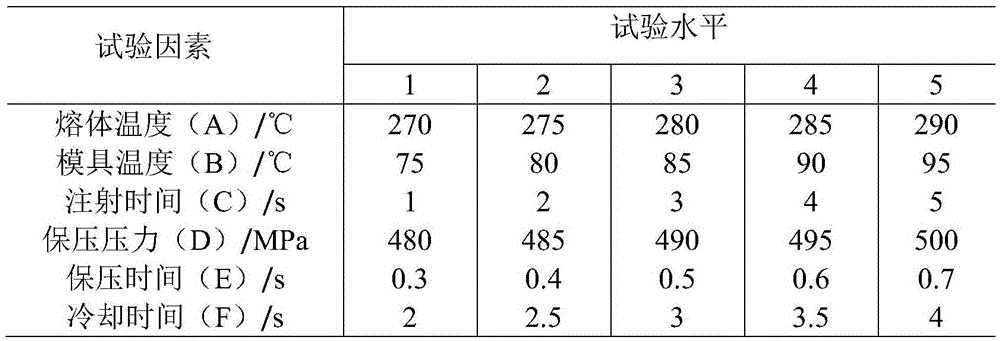

[0023] Step 2: Determine the value range of the six parameters, and determine the value range of each parameter according to the material characteristics of the product. The mold surface temperature range during injection molding is 270-290°C, and the melt temperature range is 75-95°C , the range of injection molding time is 1-5s, the range of holding pressure is 480-500MPa, the range of holding time is 0.3-0.7s, and the range of cooling time is 2-4s, as shown in Table 1;

[0024] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com