Manufacturing method of excavator bucket teeth

A technology for excavator bucket teeth and manufacturing methods, which is applied in the field of excavator bucket tooth manufacturing, and can solve problems such as failure to meet product shape and accuracy requirements, failure to guarantee product quality, and low production efficiency, so as to save time and save production costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

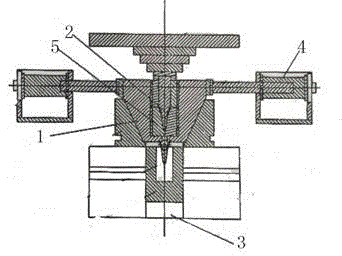

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0030] A method for manufacturing excavator bucket teeth, comprising the following steps:

[0031] Step 1: Since the hot-rolled bar from the rolling mill has a variation range of about 4% in cross-sectional area, it is actually irregular. It is not enough to control the weight of the billet only by the length of the length. Often the obtained billet If the quality is too heavy or too light, it will affect the forging of subsequent products. In order to ensure that the product quality specifications are consistent, the bar is placed on an automatic weighing device for weighing, and the mass and volume per unit length are calculated.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com