Preparation method of micro-nano SN and application of micro-nano SN

A micro-nano and reaction technology, applied in nanotechnology and other directions, can solve the problems of harsh morphology control conditions and difficult preparation process conditions, and achieve the effects of controllable morphology, simple and easy process, and reduced requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

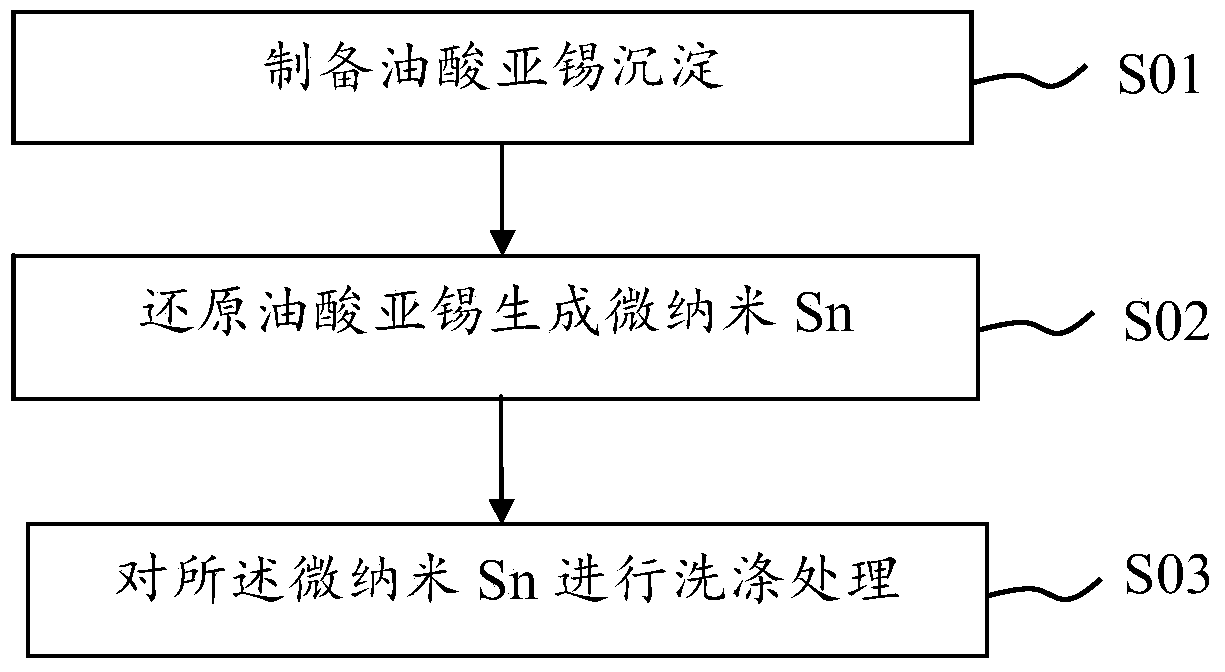

[0022] The embodiment of the present invention provides a preparation method of micro-nano Sn whose process conditions and morphology are easy to control. In one embodiment, the process flow of the preparation method of micro-nano Sn in the embodiment of the present invention is as follows figure 1 shown, including the following steps:

[0023] S01: Preparation of stannous oleate precipitation: Precipitate stannous salt with oleate surfactant in ethanol solvent to generate stannous oleate precipitation;

[0024] S02: reducing stannous oleate to generate micro-nano Sn: reducing the stannous oleate and excess reducing agent in a closed system to generate micro-nano Sn.

[0025] Specifically, in the above step S01, the stannous salt reacts with the oleate, so that the oleate ion combines with the stannous ion to form a stannous oleate precipitate. During the reaction, the oleate ions protect the stannous ions and avoid the oxidation reaction of the stannous ions, so that step S...

Embodiment 1

[0044] A method for preparing micro-nano Sn, comprising the following process steps:

[0045] Weigh 0.045g SnCl 2 2H 2 O was dissolved in 60mL of absolute ethanol, and 0.1216g of sodium oleate was added to it, and after stirring for 30-60min, excess sodium borohydride was added, sealed in a 100mL hydrothermal kettle, and the stirring speed was controlled at 500rpm. After stirring for 10 hours, a dark gray turbid liquid was obtained, which was centrifuged, washed several times with industrial alcohol, and dried in a vacuum oven.

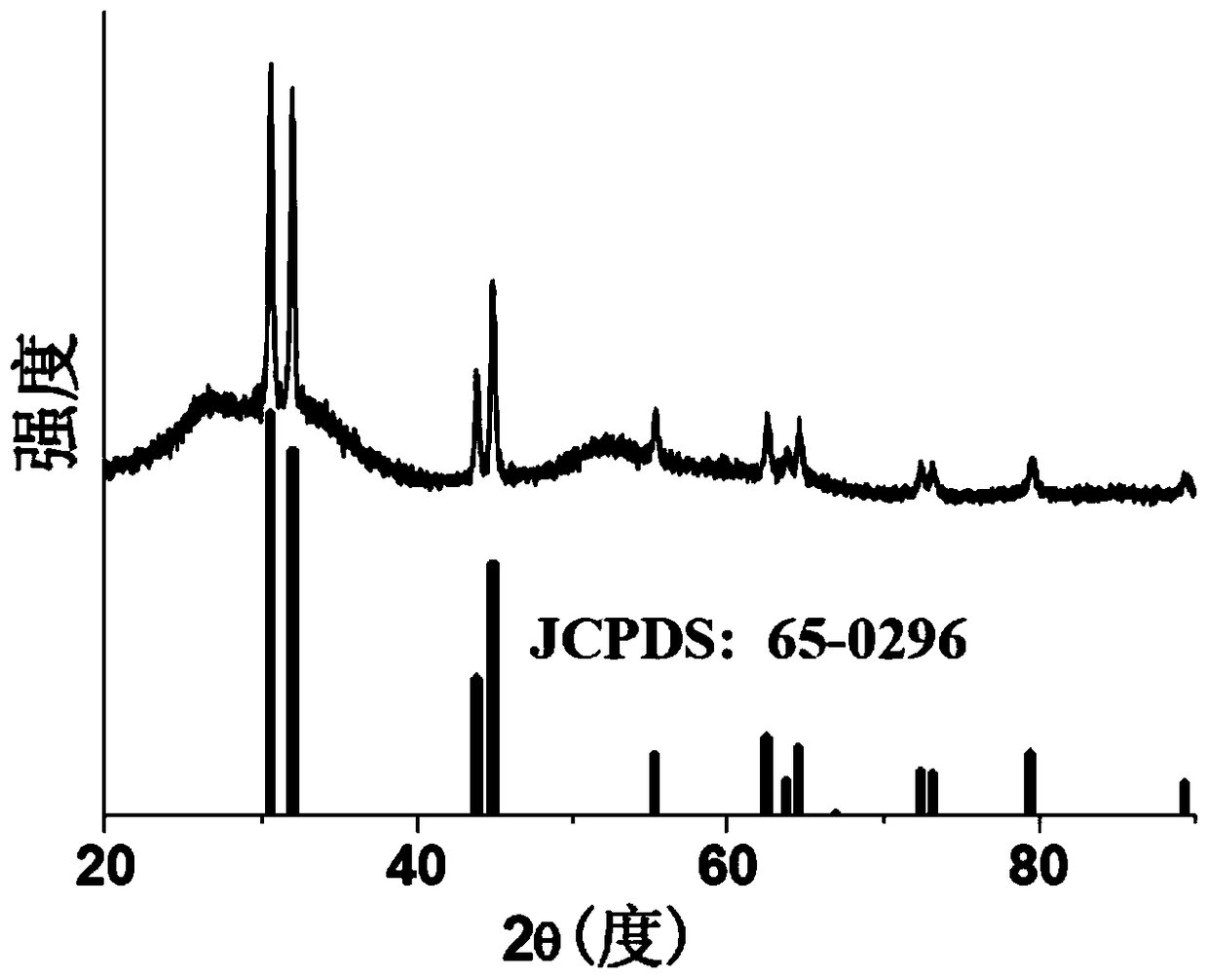

[0046] Get the sample prepared in this embodiment 1 and carry out XRD and SEM characterization, SEM characterization result is as follows figure 2 a and figure 2 As shown in b, the XRD characterization results are as follows image 3 shown. Depend on figure 2 a and figure 2 b It can be seen that the morphology of the sample powder prepared in Example 1 is mostly spherical, the particle size is mostly between 100-150nm, and there are a smal...

Embodiment 2

[0048] A method for preparing micro-nano Sn, comprising the following process steps:

[0049] Weigh 0.0337g SnCl 2 2H 2 O was dissolved in 60mL of absolute ethanol, and 0.0912g of sodium oleate was added to it, and after stirring for 30-60min, excess sodium borohydride was added, sealed in a 100mL hydrothermal kettle, and the stirring speed was controlled at 500rpm. After stirring for 10 hours, a dark gray turbid liquid was obtained, and finally the sample was treated and washed according to Embodiment 1, and the sample was dried.

[0050] The samples prepared in Example 2 were taken for XRD and SEM characterization. Among them, the SEM characterization results are as follows figure 2 c and figure 2 As shown in d, the XRD characterization results are as image 3 . Depend on figure 2 c and figure 2 d It can be seen that the sample powder prepared in Example 2 is mostly rod-shaped, with a length between 300-800nm and a width between 60-90nm. There is also a small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com