A flatness evaluation system and method based on strip transverse flatness distribution

An evaluation system and flatness technology, applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve the problem that the actual flatness defect and distribution of the strip cannot be effectively reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

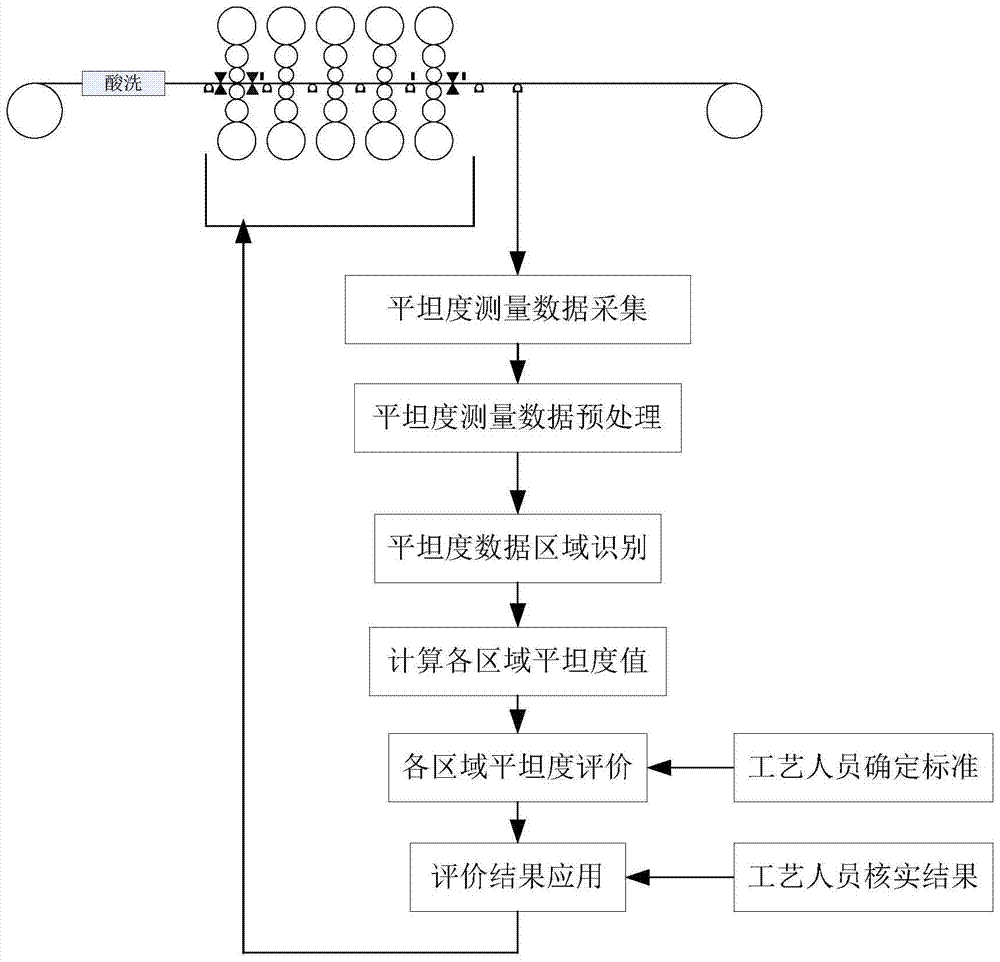

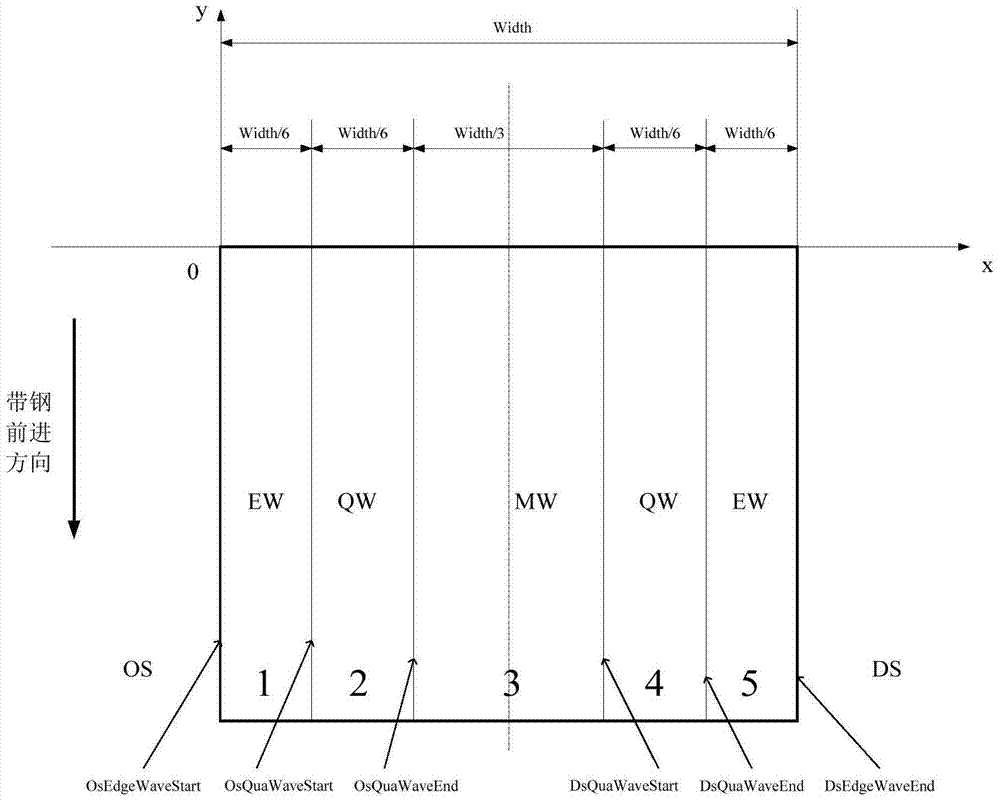

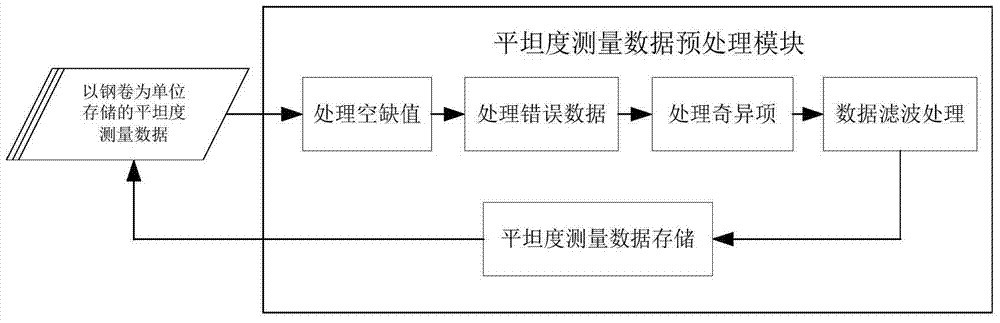

[0080] The present invention proposes a flatness evaluation system based on the strip transverse flatness distribution, which conducts flatness evaluation in different areas along the width direction of the strip, effectively solving the inability of the conventional strip flatness evaluation results based on the strip transverse mean property. The problem of effectively reflecting the actual flatness defects and distribution of strip steel is applied to the cold rolling flatness control system. The detailed description is as follows in conjunction with the drawings and examples:

[0081] Taking a concrete tandem cold rolling production line as an example, the whole process of applying the flatness evaluation system based on the strip transverse flatness distribution to it will be described in detail below.

[0082] The main parameters of the cold tandem rolling line selected in this example are:

[0083] Continuous rolling process section: SMS five-stand tandem cold rolling u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com