Coating layer, coating solution, method for forming the coating layer, and method for producing medical tool

一种涂布层、涂布液的技术,应用在对表面涂布液体的装置、涂层、医药科学等方向,能够解决医疗用具表面粘接性不充分等问题,达到耐久性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0118] Hereinafter, although an Example demonstrates invention concretely, this invention is not limited to this. In Examples and Comparative Examples, "parts" and "%" represent "parts by weight" and "% by weight", respectively, unless otherwise specified.

[0119] In the following description, the abbreviations represent the following substances, respectively.

[0120] 4,4’-MDI: 4,4’-Diphenylmethane diisocyanate.

[0121] 1,6-HDI: 1,6-hexamethylene diisocyanate.

[0122] In this example, a tube (elastomer part) made of polyamide-based elastomer resin (Pebax: trade name, polyether block amide copolymer, manufactured by ElfAtochem Corporation) and a tube (nylon part) made of nylon 12 were used. The jointed tube having an outer diameter of 1 mm and a length of 200 mm was used as an object for medical equipment.

[0123] In addition, the measurement and evaluation in the Example and the comparative example were performed by the following conditions and methods.

[0124] [eval...

Synthetic example 1

[0142] (1) Preparation of coating liquid

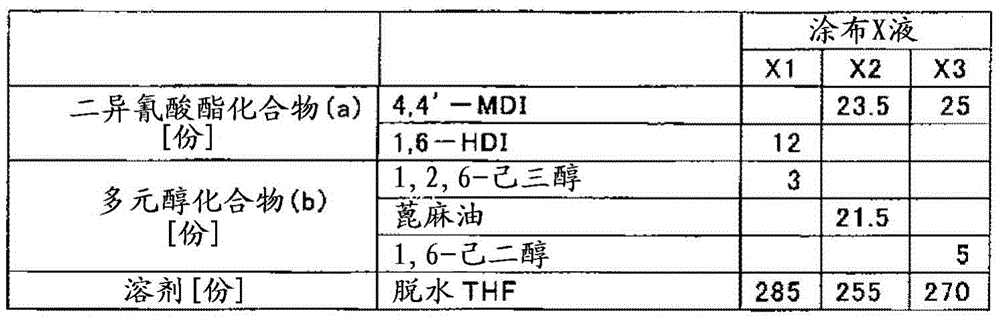

[0143] The diisocyanate compound (a) and dehydrated tetrahydrofuran (THF) were charged in a 1 L eggplant-shaped flask in proportions (parts) shown in Table 1, and the temperature was raised to 50° C. while stirring under a nitrogen stream. Further continue to stir under nitrogen stream, add polyol compound (b) in the ratio (part) shown in Table 1 to the reaction mixture in this flask simultaneously, stir at 50 ℃ for 5 hours again, obtain as (a) component Coating liquid X (X1-X3) of the polyurethane prepolymer solution which reacted with (b) component.

[0144] It should be noted that the time for adding the polyol compound (b) to the above reaction mixture is 2 hours when the polyol compound (b) is 1,2,6-hexanetriol, and 2 hours for the polyol compound (b) In the case of castor oil or 1,6-hexanediol, it is 3 hours.

[0145] [Table 1]

[0146]

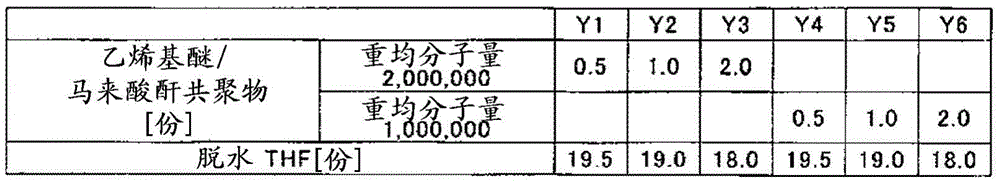

[0147] (2) Preparation of Coating Y Liquid

[0148] Next, a vinyl ether / maleic anhyd...

Embodiment 1~3

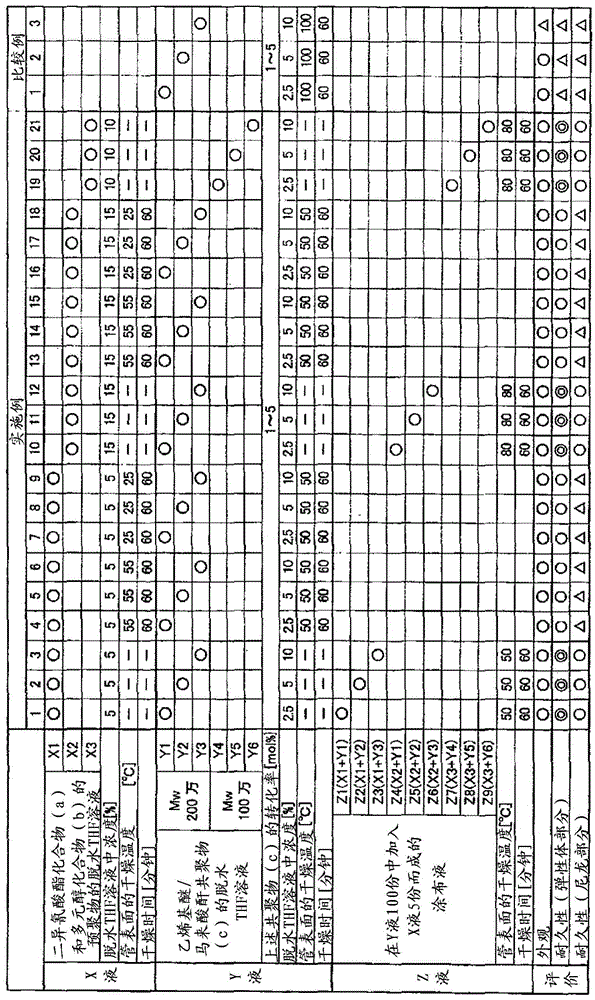

[0155] As shown in Table 3, add 5 parts of coating X1 solution to 100 parts of coating Y1, Y2 or Y3 solution to prepare coating Z1, Z2 or Z3 solution. After adjusting the liquid temperature of the obtained Z1, Z2 or Z3 liquid to about 5°C to 10°C, dip the tube as the object of medical equipment into the Z1, Z2, or Z3 liquid at a constant speed parallel to the longitudinal direction of the tube Coated and dried at 50°C for 60 minutes. The coated tube was washed twice by immersing in an aqueous sodium hydroxide solution of 0.1 to 1.0 at room temperature for 30 seconds, followed by immersing in RO water, to obtain a tube having a coated layer. The appearance and durability of the obtained tubes were evaluated. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com