Ultrasonic monitoring method for concentration of paste filling slurry conveyed in pipeline

A technology of paste filling and slurry concentration, which is applied in the direction of specific gravity measurement, measuring devices, and analysis materials, etc., can solve problems such as water loss, increase of slurry concentration, and pipeline blockage, and achieve easy installation and disassembly, convenient operation, and principle simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

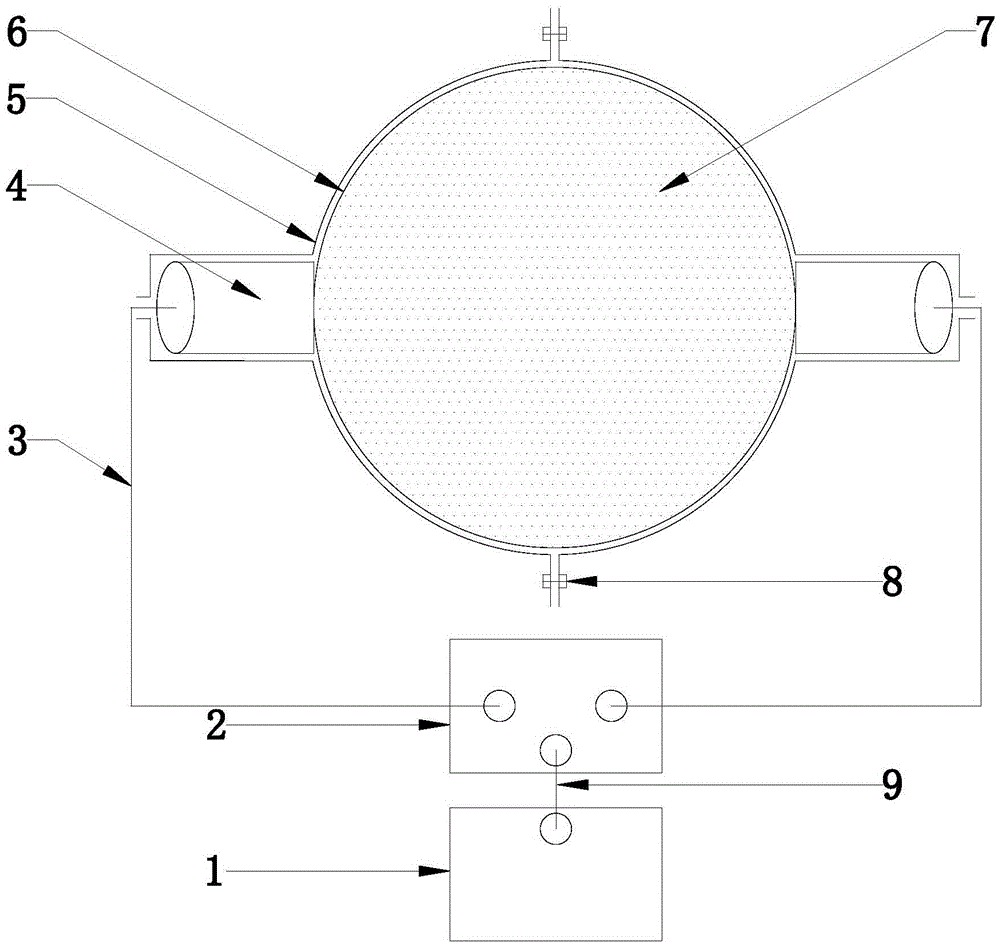

[0023] The present invention specifically implements the method process of ultrasonic monitoring pipeline conveying paste filling slurry concentration as follows:

[0024] (1) After entering the area where the paste filling slurry pipeline 6 is being transported in the mine, first find a pipeline location that is not blocked by obstacles and is convenient for monitoring and arranges measuring points; It is placed at the corresponding measuring points on both sides of the transportation pipeline 6, and is fastened with bolts 9. Connect the ultrasonic tester 2 and the sonic probe through the sonic test line 3, and connect the digital display 1 and the ultrasonic tester 2 through the sonic data line 10.

[0025] (2) When working, turn on the ultrasonic tester 2 and press the zero-adjustment button to adjust the zero. After the zero-adjustment, set the pipe distance to the outer diameter of the measured pipeline 6, and press the sampling button to collect the paste slurry being tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com