A device and method for preventing wall sticking of spray drying tower

A spray drying tower and wall sticking technology, which is applied in the direction of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of viscous materials sticking to the wall, etc., to increase the uniformity, improve the quality of dried products, and simplify the process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the embodiments and the drawings.

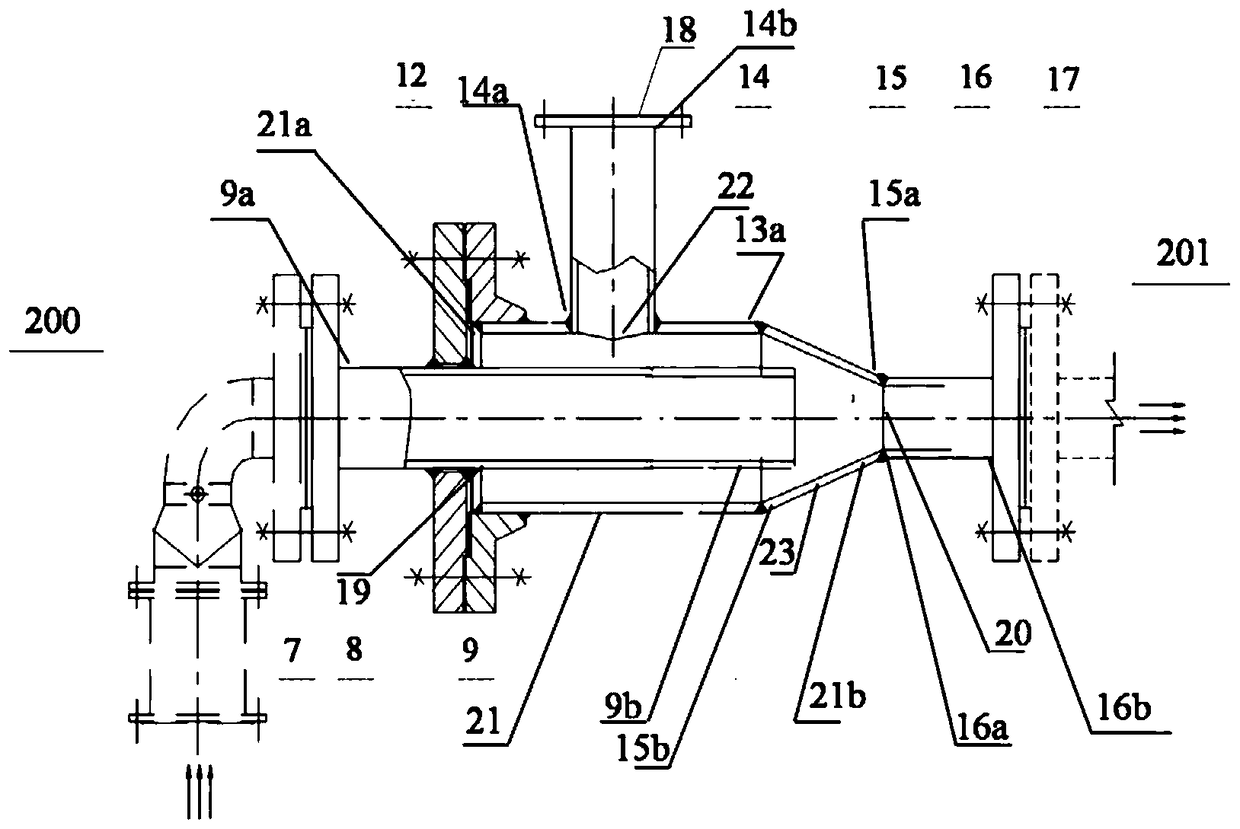

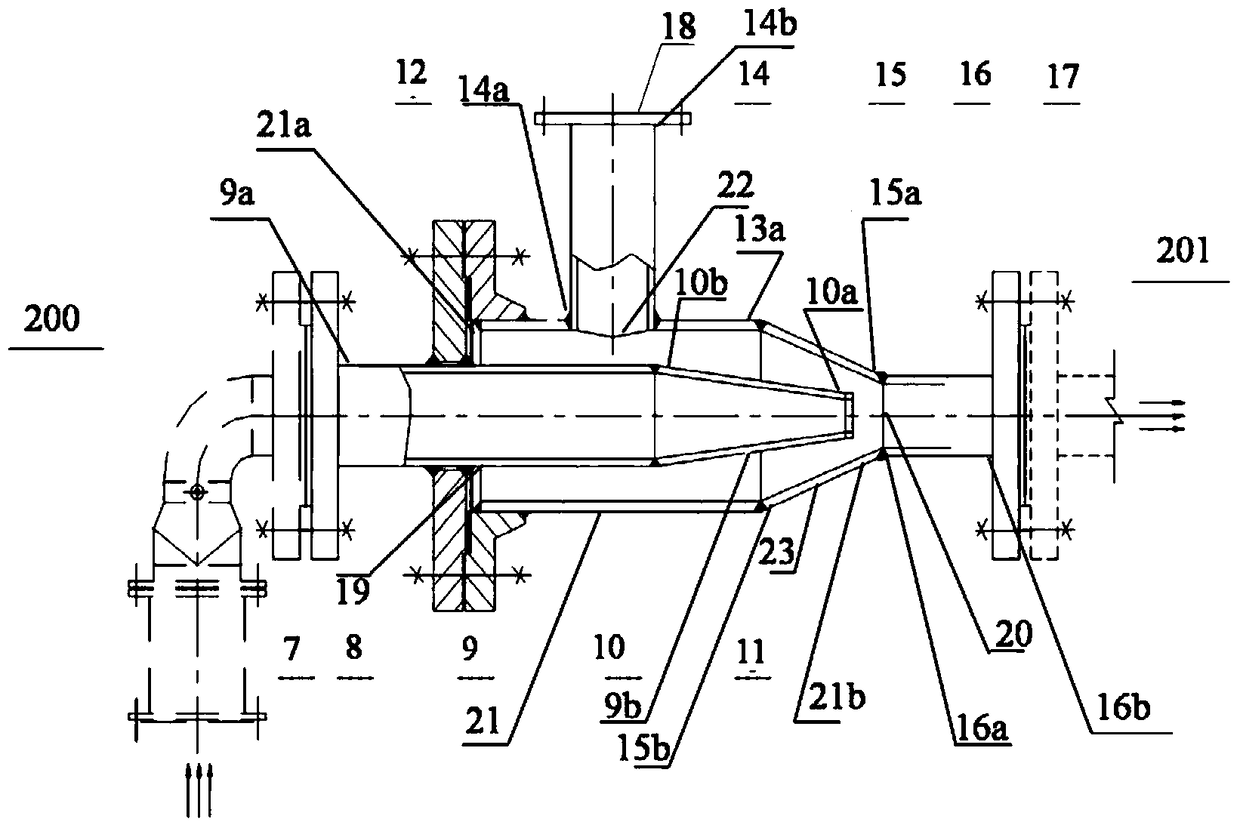

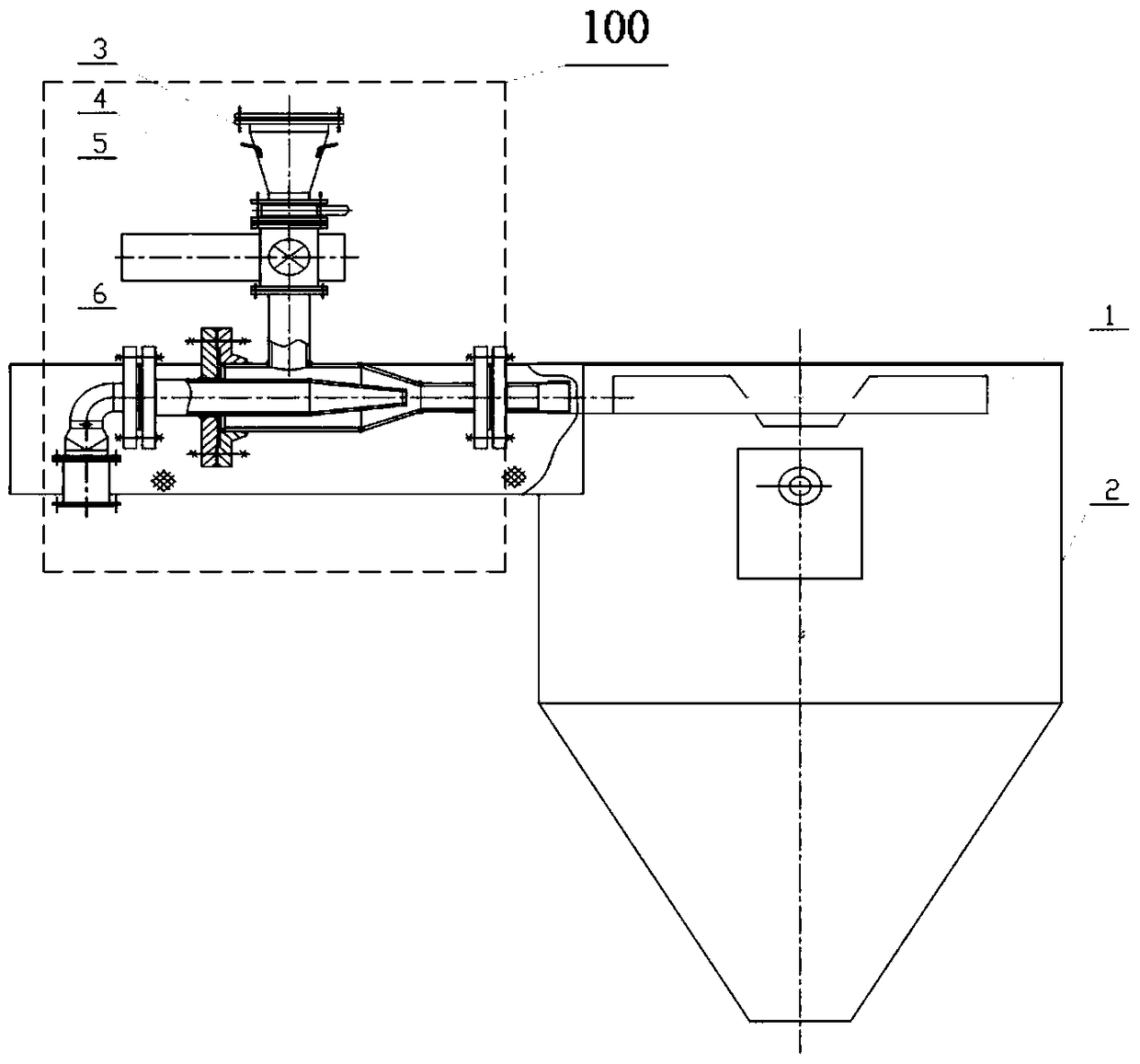

[0027] The mechanism for preventing the spray drying tower from sticking to the wall according to the present invention, such as figure 1 As shown, the device includes an outer cylinder 21 with an air inlet 19 and an air outlet 20; and a suction port 22 provided on the outer cylinder for providing anti-sticking material in the outer cylinder 21; wherein, in the outer cylinder 21 The flowing airflow carries the anti-sticking material and flows out through the air outlet 20. The outer cylinder 21 may be made of metal or heat-resistant material, and the outer cylinder 21 made of the material can meet the requirements of heat-resistant wind. After the gas with anti-sticking materials enters the drying tower cylinder 2 (such as image 3 ), it can be dispersed to various parts in the drying tower to improve the phenomenon of sticky materials sticking to the wall. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com