A preparing method of a ternary copolymerized water reducer

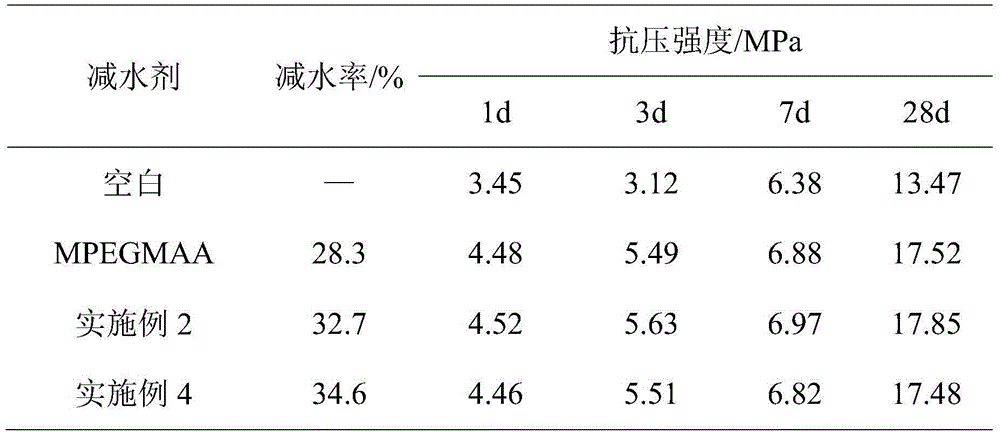

A technology of water reducer and copolymerization, which is applied in the field of preparation of ternary copolymerization water reducer, which can solve the problems of high price of MPEGMAA, long production cycle of naphthalene-based water reducer, serious environmental pollution, etc., and improve the early strength and final strength , good market competitiveness, good cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the ternary copolymerization water reducer of the present invention comprises the following steps:

[0020] Step 1: Add a certain amount of water, modified polyether allyl polyoxyethylene ether or methallyl polyoxyethylene ether, molecular weight regulator dodecyl mercaptan to the reactor, modify polyether and The mass ratio of water is 1:200-300, the dosage of the molecular weight regulator is 1%-3% of the modified polyether, and the modified polyether solution is obtained by stirring and dissolving;

[0021] Step 2: Heat the modified polyether solution obtained in step 1 to 70°C to 85°C, then add the mixed monomer acrylic acid and acrylamide and the aqueous initiator solution, and the moles of acrylic acid and modified polyether The ratio is 1~1.6:1, the molar ratio of acrylamide to modified polyether is 0.5~1.3:1, the initiator is ammonium persulfate or potassium persulfate, and the amount of initiator is 1%~ of the total mass of acrylic aci...

Embodiment 1

[0025] Step 1: Add a certain amount of water, allyl polyoxyethylene ether (APEG-2400), molecular weight regulator dodecyl mercaptan to the reactor, and the mass ratio of allyl polyoxyethylene ether to water is 1 : 200, the consumption of molecular weight regulator is 1% of allyl polyoxyethylene ether, stirring and dissolving obtains allyl polyoxyethylene ether solution;

[0026] Step 2: Heat the allyl polyoxyethylene ether solution obtained in step 1 to 70°C, then add the mixed monomers of acrylic acid, acrylamide and ammonium persulfate aqueous solution, acrylic acid and allyl polyoxyethylene ether dropwise within 1 hour The molar ratio of acrylamide to allyl polyoxyethylene ether is 1:1, the molar ratio of acrylamide to allyl polyoxyethylene ether is 0.5:1, the amount of ammonium persulfate is 1% of the total mass of acrylic acid and acrylamide, and the ammonium persulfate and The mass ratio of water is 1:5, after the mixed monomer and the ammonium persulfate aqueous solutio...

Embodiment 2

[0029] Step 1: Add a certain amount of water, methallyl polyoxyethylene ether (TPEG-2400), molecular weight regulator dodecyl mercaptan, and the mixture of methallyl polyoxyethylene ether and water into the reactor The mass ratio is 1:300, the amount of the molecular weight regulator is 2% of the allyl polyoxyethylene ether, stirring and dissolving to obtain the methallyl polyoxyethylene ether solution;

[0030] Step 2: Heat the methallyl polyoxyethylene ether solution obtained in step 1 to 75°C, and then add the mixed monomers acrylic acid and acrylamide and ammonium persulfate aqueous solution, acrylic acid and methacrylic acid simultaneously within 1.5 hours The molar ratio of polyoxyethylene ether is 1.3:1, the molar ratio of acrylamide to methallyl polyoxyethylene ether is 0.9:1, and the amount of ammonium persulfate is 4% of the mass sum of acrylic acid and acrylamide. The mass ratio of ammonium persulfate to water in the ammonium aqueous solution is 1:7. After the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com