Novel high-temperature heating disinfecting anti-bacteria pharmacy production line

A high-temperature heating and high-temperature disinfection technology is applied in the direction of synchronous devices, bottle filling, bottling machines, etc. It can solve the problems of increased labor costs, power consumption, and low temperature, so as to save time for pharmaceuticals, reduce labor costs, and ensure filling. The effect of loading quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

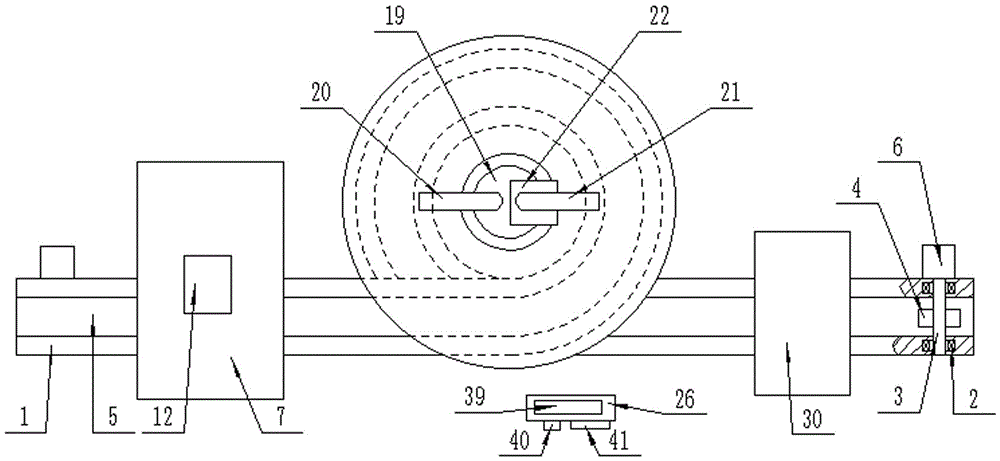

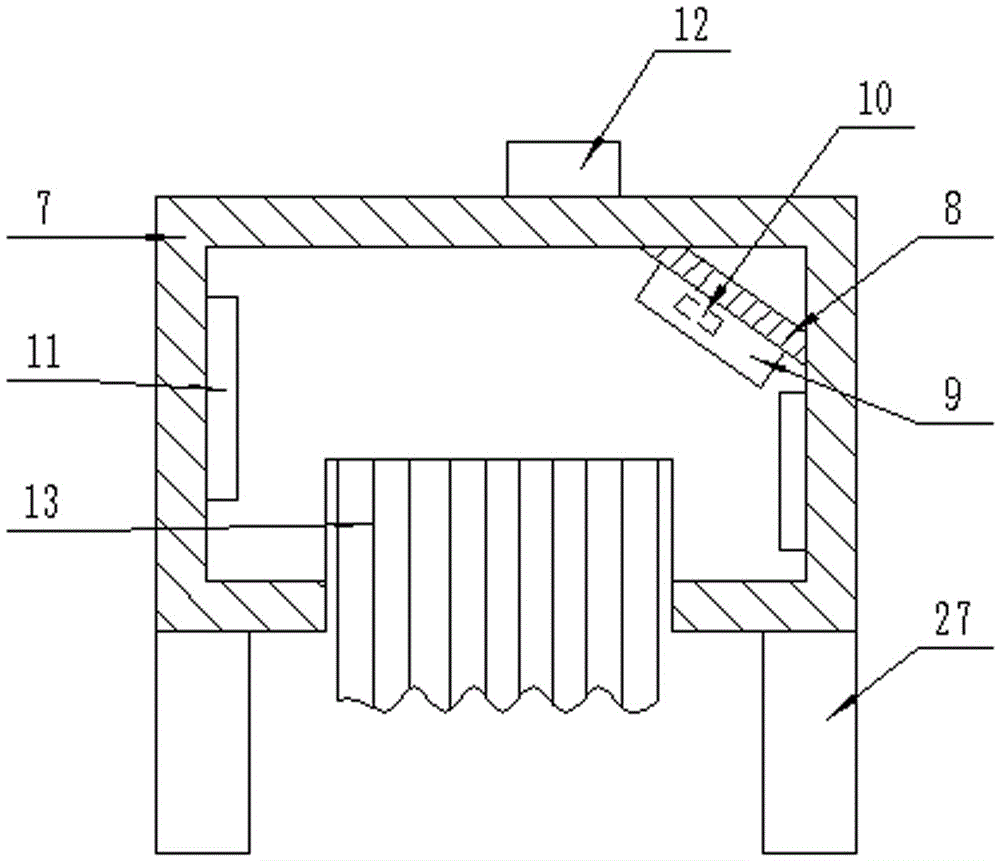

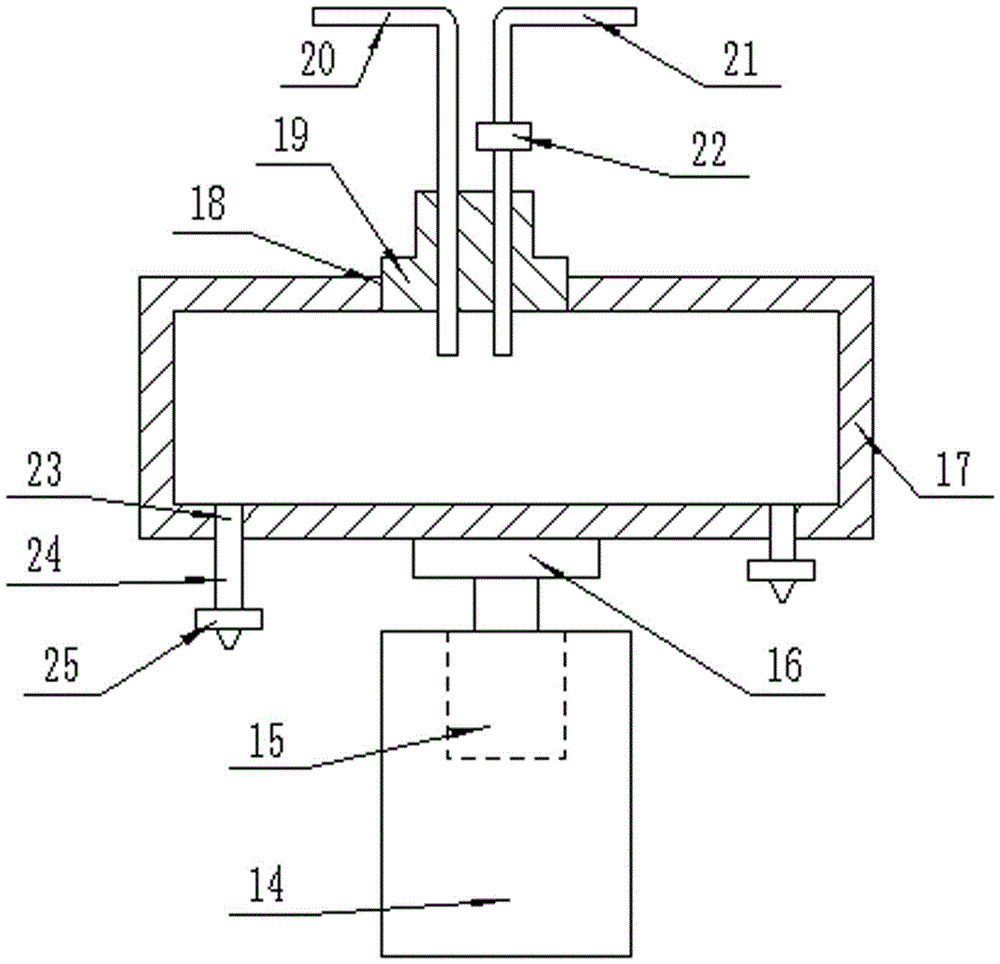

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a new type of high-temperature heating, disinfection and antibacterial pharmaceutical production line includes an annular support (1), the annular support (1) is fixedly installed on the ground, and a chain-type endless conveyor belt mechanism is arranged inside the annular support (1). The chain type endless conveyor belt mechanism consists of multiple sets of bearings (2) located on the inner wall of the ring bracket (1), a rotating shaft (3) inserted in the bearing (2), and a gear fixedly sleeved on the rotating shaft (3) ( 4), an annular wide transmission chain (5) that engages with each gear (4), and two drive motors (6) that are fixedly installed at both ends of the annular support (1) and fixedly connected with the rotating shafts (3) at both ends ), one end of the annular support (1) is provided with a high-temperature sterilization and disinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com