Automatic base plate top block of mulch applicator workbench

A workbench, laminating machine technology, applied in chemical instruments and methods, layered products, lamination, etc., can solve the problems of controlling the lifting and lowering of the top block, and reduce the operating space, improve the adaptability and limitations. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

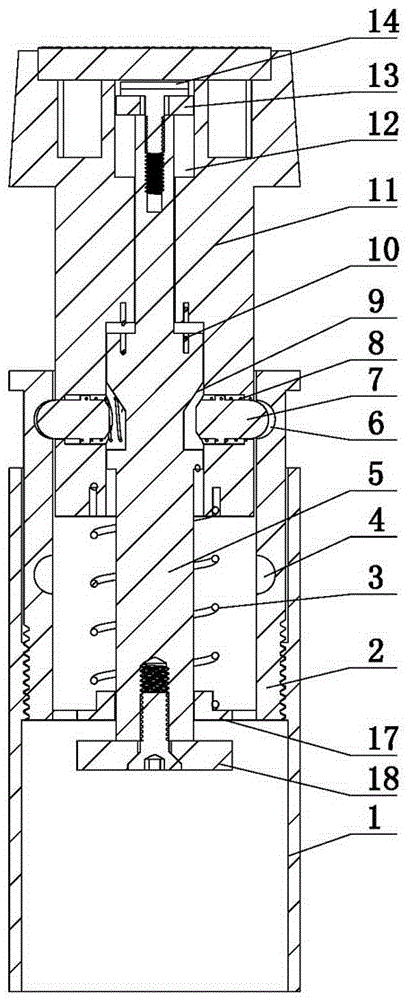

[0015] The present invention includes a casing 1, which is characterized in that: the casing 1 is provided with a fixed sleeve 2, the fixed sleeve 2 is provided with a lifting sleeve 11, and the lifting sleeve 11 is provided with a mandrel 5; the upper end of the mandrel 5 is set through a fixing member 14 There is a driving magnet 13, and the upper end of the lifting sleeve 11 is provided with a positioning groove 12 corresponding to the fixing piece 14; a horizontal locking block 7 is arranged in the lifting sleeve 11 through a locking spring 8; There is a receiving groove 20; the upper limit groove 6 and the lower limit groove 4 that can cooperate with the locking block 7 are arranged in the fixed sleeve 2; a push-down spring 10 is arranged between the mandrel 5 and the lifting sleeve 11, and the A locking slope 9 is provided above the receiving groove 20 corresponding to the locking block 7 .

[0016] A jacking spring 3 is arranged between the lifting sleeve 11 and the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com