Novel water-type mold temperature controller apparatus

A mold temperature machine, water-type technology, applied in the field of new water-type mold temperature machine devices, can solve problems such as affecting safe production, water tank scrap, misoperation, etc., to prevent dry burning phenomenon, prevent dry burning phenomenon, and control temperature. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

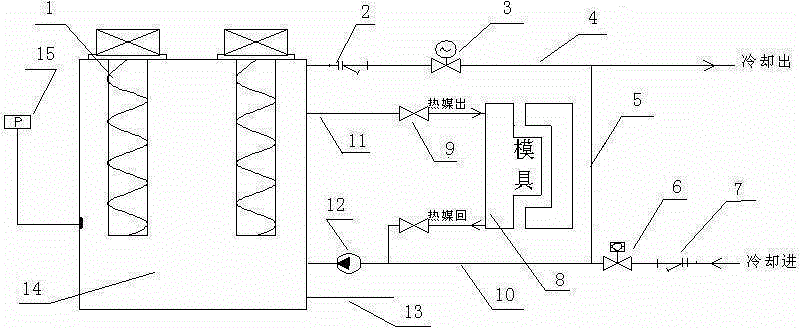

[0034] see figure 1 Shown, the present invention comprises water tank 14, heating device 1, water inlet pipe 10, water outlet pipe 4, pressure switch 15 and blowdown outlet 13, and the work flow of the present invention is:

[0035] 1) The cooling water passes through the filter 7, the water flow switch 6, and the circulation pump 12 enters the water tank 14, and the air and water in the water tank 14 pass through the outlet pipe 4 connected to the upper part of the water tank, pass through the impurities to block the solenoid valve 2, and then turn on and off the solenoid valve 3 to flow out . Detect the data of pressure switch 15, when water tank 14 pressure is enough, circulation pump 12 starts.

[0036] 2) Turn on the heating switch. After the circulation pump 12 runs for three minutes, the heating device 1 starts to work. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com