Operator support system, operator support method and component mounting apparatus

A technology for installing devices and supporting systems, applied in general control systems, electrically operated teaching aids, control/regulation systems, etc., can solve problems such as the reduction of equipment operation rate, the delay in improving the level of operation skills, and the difficulty in preventing equipment operation rate, etc. The effect of improving operation skills and preventing the reduction of equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

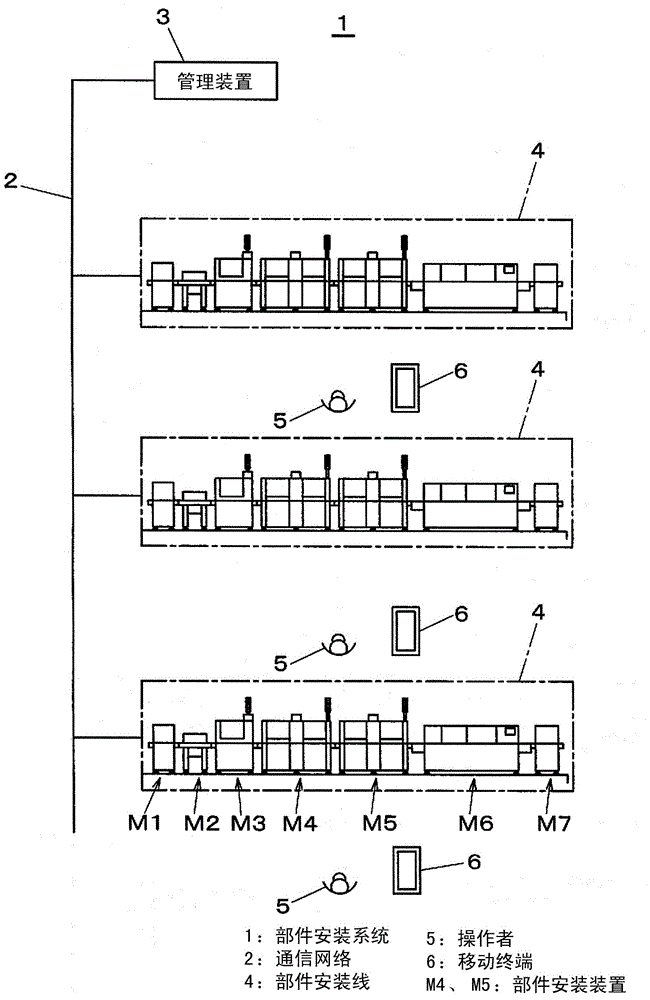

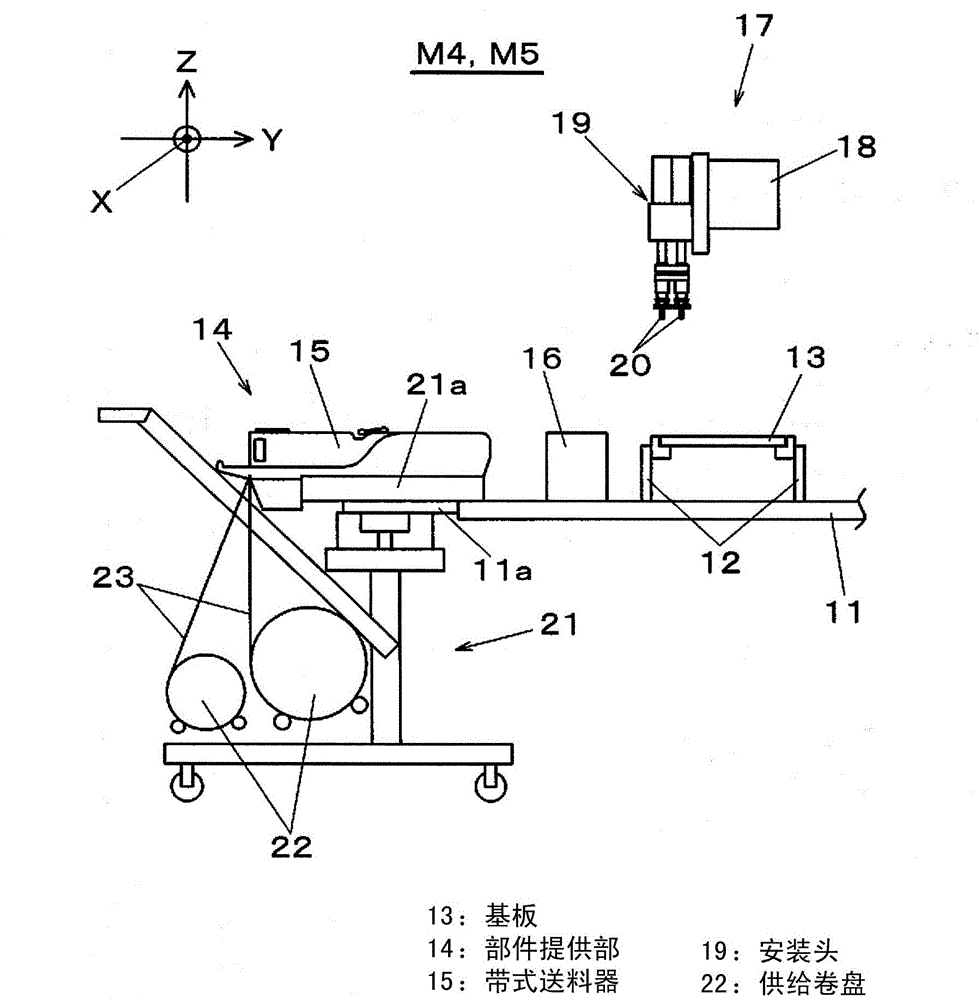

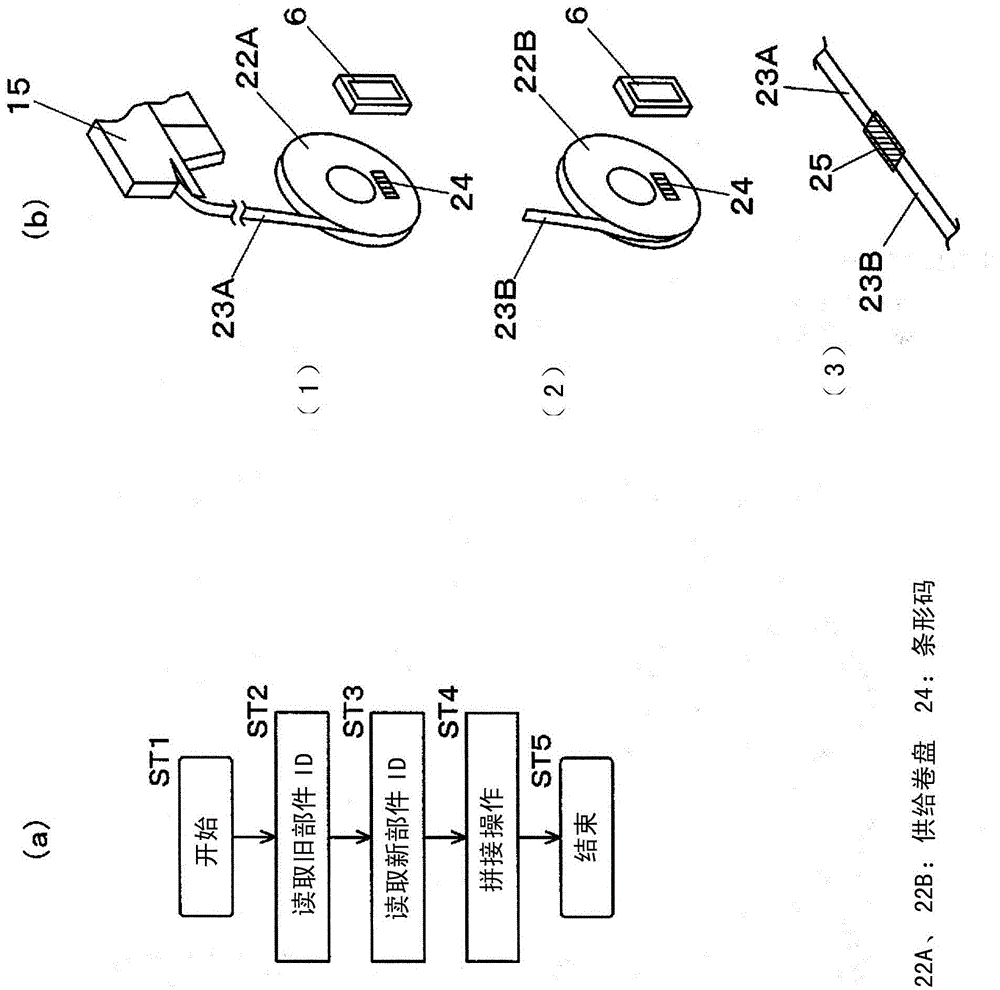

[0035] Embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , the configuration of the component mounting system 1 to which the operator support system of the present embodiment is applied will be described. The component mounting system 1 has a function of mounting electronic components on a substrate to generate a mounted substrate. In the present embodiment, a plurality of component mounting lines 4 are connected to the management device 3 via the communication network 2, and operators 5 assigned to each component mounting line 4 perform various operations for device operation. At this time, the mobile terminal 6 owned by each operator 5 is used as necessary. Operations in each component mounting line 4 are managed by the management device 3 . That is, the management device 3 transmits the data necessary for the operation of each device belonging to the component mounting line 4 to the device, and transmits the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com