Touch panel and preparation method thereof

A technology of a touch panel and a manufacturing method, which are applied in the directions of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of the complex structure of the capacitive touch screen film layer, reduce the manufacturing cost, etc. The effect of manufacturing cost, improving overall strength, and simplifying film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the touch panel provided by the present invention and the manufacturing method thereof, a detailed description will be given below in conjunction with the accompanying drawings and text descriptions of the specification.

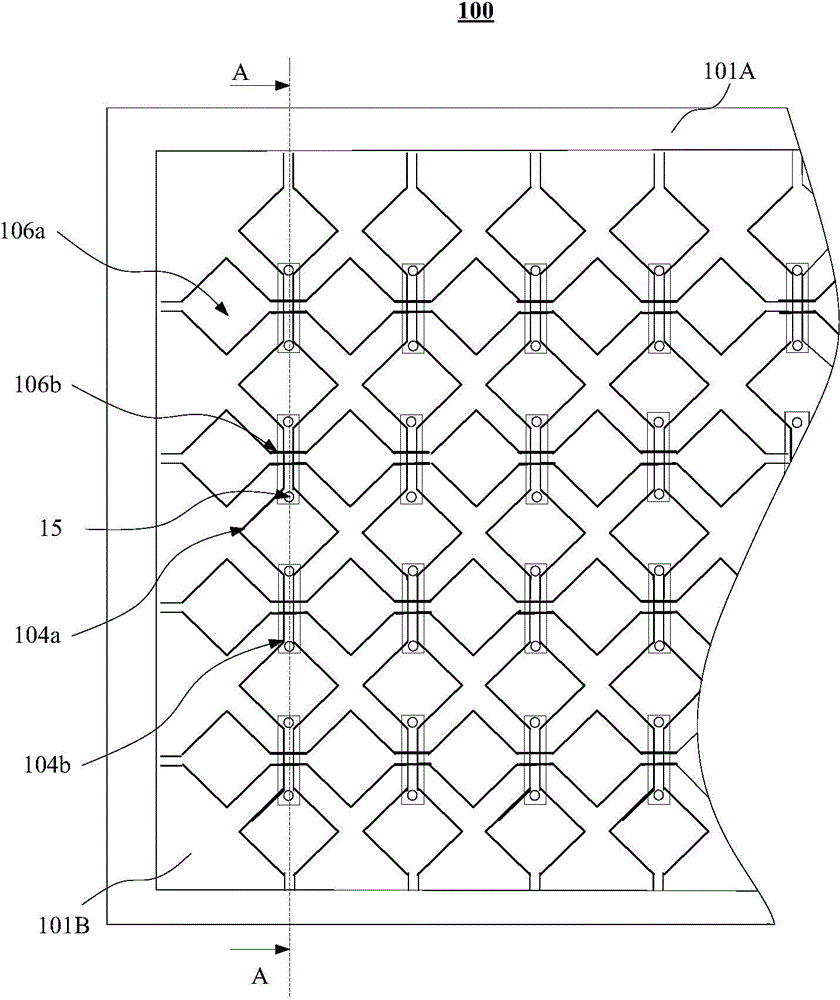

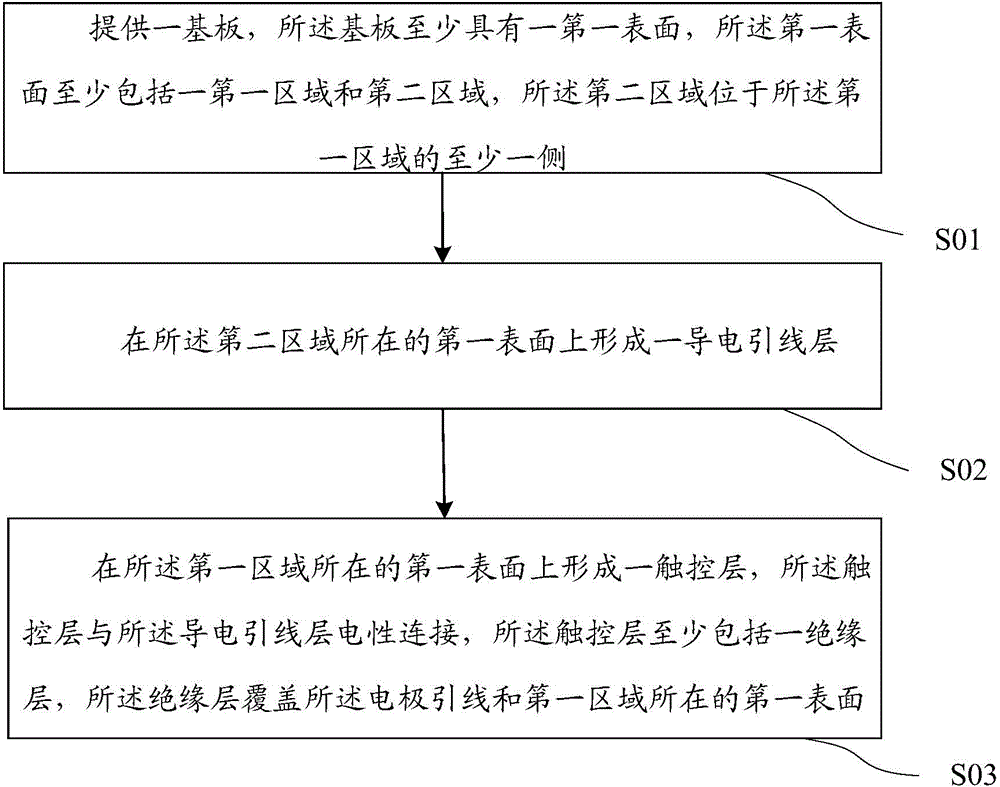

[0022] Please refer to figure 1 , figure 2 , which is a schematic structural diagram of a touch panel 100 according to a preferred embodiment of the present invention and a schematic structural diagram of the touch panel 100 along the direction A-A. The touch panel 100 at least includes a substrate 101 , a shielding layer 102 , a conductive lead layer 103 and a touch layer.

[0023] The substrate 101 has at least a first surface 101a, and the first surface 101a is a plane. In other embodiments, the first surface may also be a curved surface or an irregular surface. The substrate 101 is made of transparent materials such as glass and resin. The first surface 101a includes at least a first region 101A and a second region 101B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com