An anti-reflection film used in an anti-blue light spectacle lens

An anti-reflection film and blue-light eye technology, which is applied in optics, optical components, instruments, etc., can solve the problems of anti-blue-light glasses that have not yet appeared, the color of the film has little effect, and the appearance has no effect, so as to protect the eyes and improve visual contrast. , increase the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

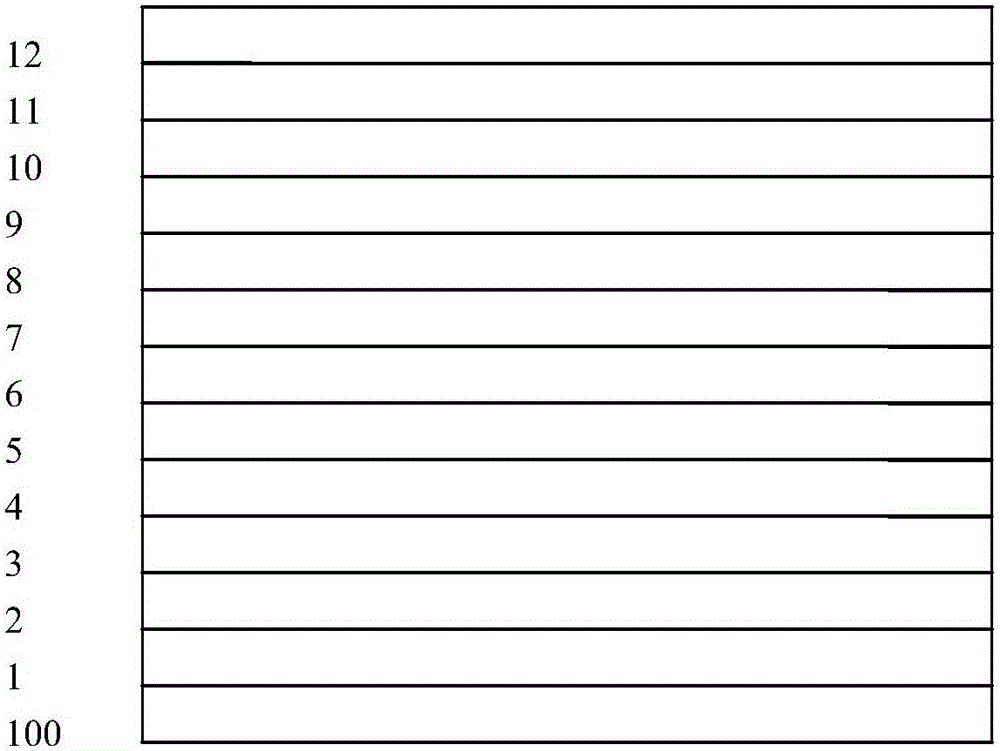

[0017] Such as figure 1 As shown, the anti-reflection film for spectacle lenses provided by the present invention includes a first silicon dioxide layer 1, a first zirconium oxide layer 2, a second silicon dioxide layer 3, a first titanium oxide layer in the order of being away from the lens substrate 100. Layer 4, first aluminum oxide layer 5, second zirconium oxide layer 6, first silicon carbonate layer 7, second titanium oxide layer 8, second silicon carbonate layer 9, second aluminum oxide layer 10, third silicon dioxide layer 11 , in addition, it also includes a conductive layer 12 formed of indium tin oxide.

[0018] In the present invention, the anti-reflection film is used for anti-blue light glasses.

[0019] According to the invention, the antireflection film comprises at least one high-refractive-index layer and at least one low-refractive-index layer. It is formed into a structure of 7-11 layers, and the high-refractive-index layers and low-refractive-index layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com